In the mineral processing industry, ore crushing serves as the primary step, directly determining the efficiency and cost of subsequent separation and purification processes. Given the significant variations in physical properties (such as hardness, grain size distribution, and clay content) among different metal ores, crushing solutions must be tailored to specific requirements. This article systematically outlines crushing processes for typical metal ores like copper, gold, and lead-zinc, analyzes key equipment selection and process optimization strategies, helping you grasp core concepts in just 3 minutes.

I. Matching Crushing Equipment to Ore Characteristics

Metal ore crushing must be tailored to ore type and properties. For example:

Copper Ore: Sulfide copper ores exhibit high hardness and coarse grain size, requiring strong impact crushing.

Gold Ore: Primary gold ores often occur with quartz veins, necessitating high-capacity equipment.

Lead-Zinc Ore: High sulfur content causes adhesion, necessitating anti-clogging designs.

II. Detailed Explanation of Staged Crushing Processes

1. Primary Crushing Stage: The “Initial Gatekeeper” for Large Ore Blocks

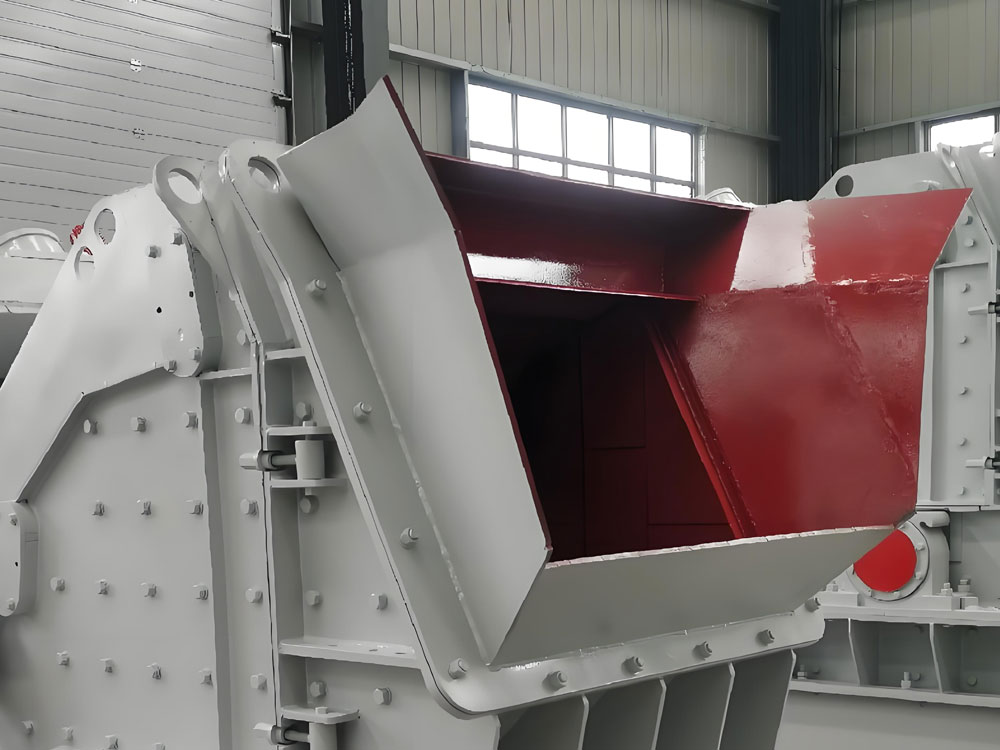

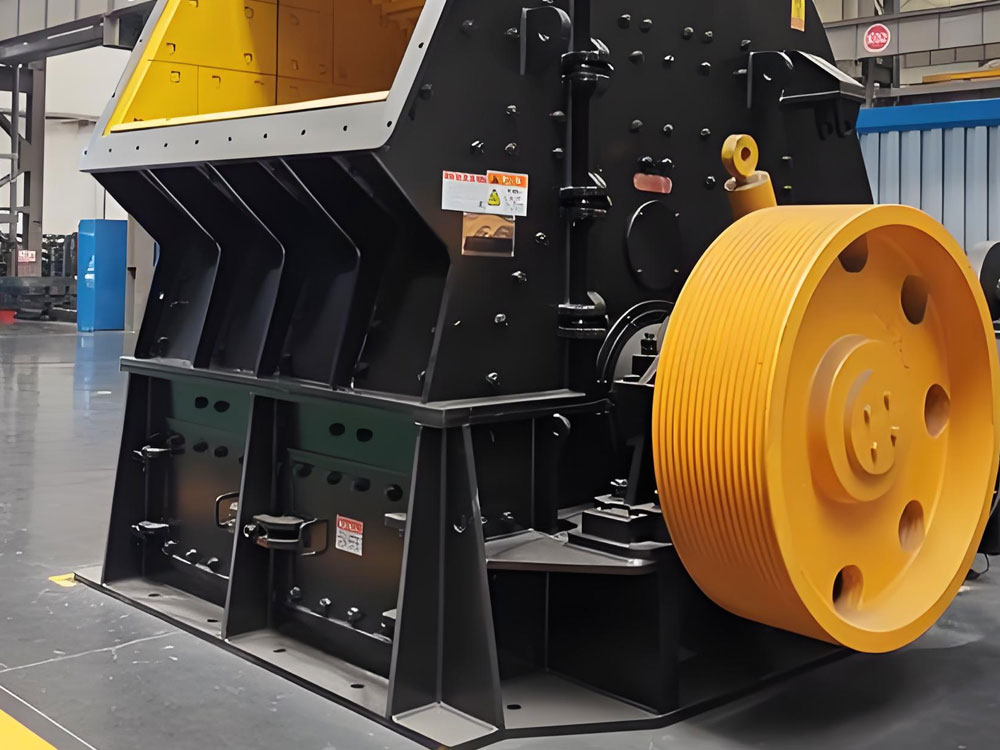

Primary Equipment: Jaw Crusher

Capacity: Up to 1000 tons/hour (Example: PE1200×1500 model)

Feed Size: Maximum 1000 mm

Discharge Size: 50–200 mm

Applications: High-hardness ores (e.g., copper sulfide, primary gold ore)

Case Study: Dexing Copper Mine in Jiangxi employs jaw crushers with single-unit daily throughput exceeding 20,000 tons.

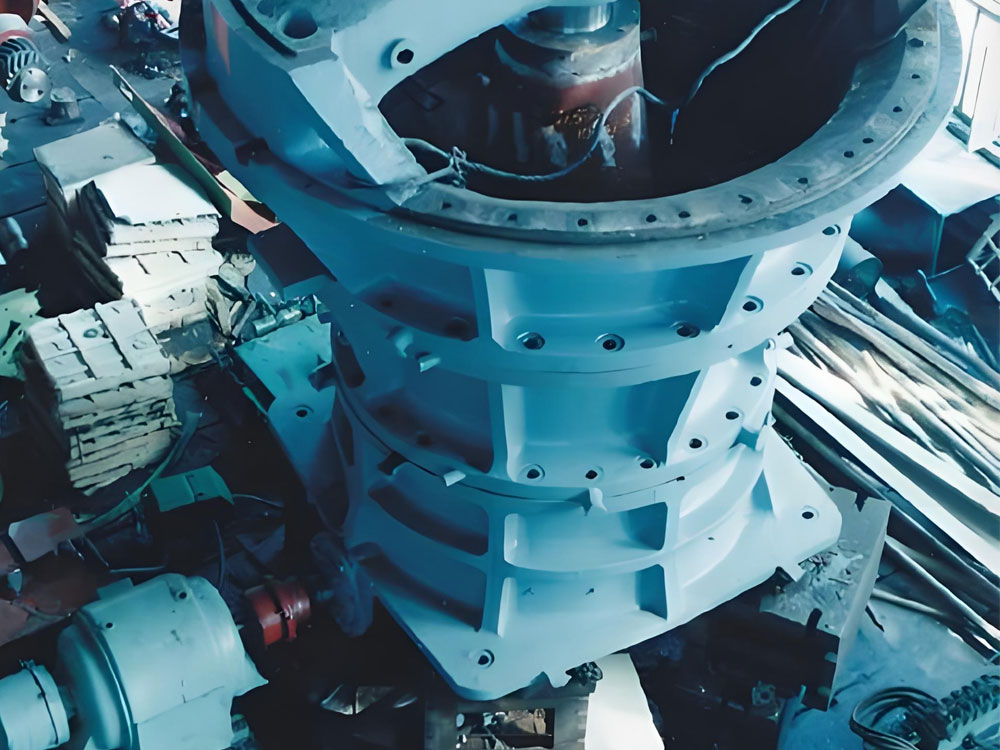

Upgrade Option: Gyratory Crusher

Advantages: High crushing ratio (up to 8:1), 15%-20% reduced energy consumption

Applications: Ultra-large mines (e.g., Escondida Copper Mine, Chile)

Supporting Equipment: Vibrating Feeder

Function: Ensures uniform feeding to prevent equipment overload

Efficiency Boost: Reduces material blockage failures by 20%.

2. Medium-Fine Crushing Stage: Precision Surgery for Particle Size Control

Cone Crusher

Principle: Layer compression crushing, uniform output size (10-50 mm)

Applications: Medium-hard or high-sulfur ores (e.g., lead-zinc ore)

Case Study: Yunnan Huize Lead-Zinc Mine employs HPC hydraulic cone crushers, achieving 92% product size compliance.

Impact Crusher

Advantages: High crushing ratio (up to 40:1), excellent particle shape (cubic particles >85%)

Limitations: Rapid wear of wear parts (service life ~3000 hours)

Applications: Medium-hard ores (e.g., certain copper oxide ores)

Screening Equipment: Single-deck vibrating screen

Function: Separates qualified particle sizes, returns unqualified material

Efficiency Metric: Screening efficiency ≥90%.

3. Fine Crushing Stage: “Precision Polishing” for Final Particle Size

Short-head Cone Crusher

Discharge Size: 3-20 mm

Applications: Final crushing of hard ores

Roller Crusher

Advantages: Controllable particle size (adjustable below 2 mm)

Limitations: Low throughput (approx. 500 t/h per unit)

Vertical Impact Crusher

Applications: Brittle ores (e.g., certain gold deposits)

Size adjustment: Speed control (1000-1500 rpm)

Auxiliary equipment: Double-deck vibrating screen

Function: Enables closed-circuit operation to reduce over-crushing

Case study: Olympic Dam copper mine in Australia employs double-deck screening, reducing circulating load to 25%.

III. Optimization Strategies for Crushing Processes

1. Classic Process: Three-Stage Closed-Circuit

Flow: Primary crushing → Secondary crushing → Tertiary crushing + Screening

Advantages: 30% energy reduction, 25% efficiency increase

Applicable Scenarios: Large-scale mineral processing plants (e.g., Las Bambas Copper Mine, Peru)

2. Simplified Process: Two-Stage Closed-Circuit

Flow: Primary crushing → Tertiary crushing + Screening

Advantages: 40% reduction in equipment investment, 30% space savings

Suitable Scenarios: Small-to-medium scale operations or low-hardness ores (e.g., certain iron ores)

IV. Efficiency Enhancement Practices for Special Processes

1. High-Pressure Roller Mill

Principle: Layer crushing reduces energy consumption by 40%-50%

Case: ThyssenKrupp's application at Chilean copper mines reduced specific power consumption to 1.2 kWh/t.

2. Intelligent Control System

Technology: PLC + IoT

Function: Real-time monitoring of current, temperature, and other parameters with 95% fault prediction accuracy

Benefits: 60% reduction in unplanned downtime, 10%-15% energy optimization

3. Environmental Protection Measures

Enclosed crushing chamber + pulse dust collector

Effect: Dust emission concentration ≤10mg/m³ (far below the national standard of 30mg/m³)

Case Study: After implementation at Zijin Mining's operations, surrounding residents' complaints decreased by 90%.

V. Practical Case Studies and Selection Recommendations

1. Typical Metal Ore Crushing Solutions

Copper Ore: Jaw Crusher (primary crushing) + Cone Crusher (secondary/tertiary crushing) + Three-stage closed-circuit process

Case Study: Minmetals Resources Las Bambas Copper Mine, annual processing capacity of 120 million tons.

Gold Ore: Mobile Crushing Station (integrated primary and secondary crushing)

Advantages: Deployment completed in 7 days, flexible response to dispersed ore sites

Case Study: Shandong Gold Group overseas project, reducing commissioning time by 50%.

Lead-Zinc Ore: Impact Crusher (fine crushing)

Outcome: 8% recovery rate increase, generating over ¥20 million in annual benefits.

2. Key Equipment Selection Criteria

Hardness Matching: High hardness—jaw/cone crushers; low hardness—impact crushers.

Scale Adaptation: Heavy-duty equipment (e.g., 1200 t/h jaw crusher) for large mines; mobile units for small-to-medium operations.

Maintenance Costs:

Chromium-molybdenum alloy liners: 8000-hour lifespan, ¥50,000/set;

Coated steel plates: 5000-hour lifespan, ¥20,000/set, offering superior cost-effectiveness.

VI. Future Trends: Green and Intelligent

With the advancement of carbon neutrality goals, crushing processes are evolving toward low-carbon and digital solutions. For instance, a leading enterprise has piloted hydrogen-powered crushers, reducing annual carbon emissions by 2,000 tons per unit. AI vision systems can identify ore hardness in real time, dynamically adjusting crushing parameters to boost efficiency by 18%.

Enhancing ore crushing efficiency fundamentally requires synergistic innovation across equipment, processes, and management. By precisely matching ore characteristics, optimizing process design, and integrating intelligent technologies, mineral processing plants can achieve dual breakthroughs in cost reduction and output while ensuring environmental compliance.