China Maxizm Mobile Jaw Crusher Nord-track J127

Nordtrack J127 mobile jaw crusher is designed to meet the needs of specific industries. Its crawler chassis makes this equipment excellent in various fields such as asphalt recycling, construction waste reuse and aggregate production, and is especially suitable for short-term contract operations. Operate with novices. Its wide crusher feed inlet and optimized two-stage feeding mechanism design greatly improve the processing capacity. In addition, the equipment also provides an optional high-efficiency iron removal device, equipped with a high-flow large-diameter jaw crusher, and stable material transfer functions to ensure efficient operations. The Nordtrack J127 is also distinguished by its mobility, ease of operation and smoothness. Its large-capacity feeder, which is easy to quickly deploy and store, and its hydraulically adjustable side conveyor belts further improve the equipment's availability and durability, ensuring continued and efficient production.

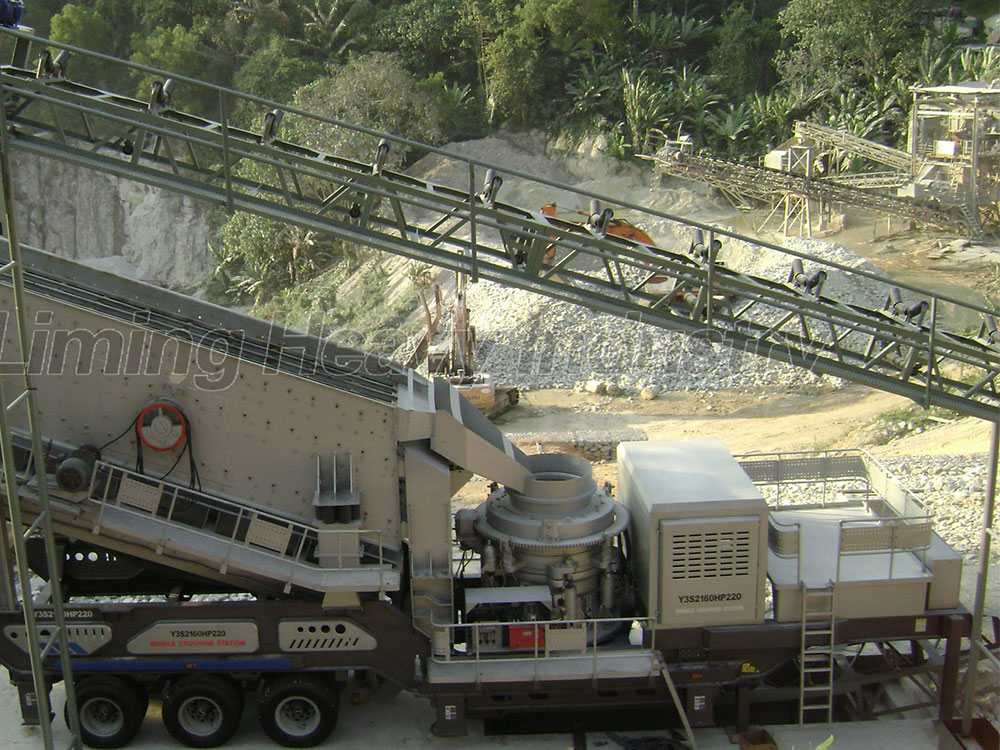

China Maxizm Mobile Jaw Crusher Nord-track J127 Applications

In the field of mining, the Nordtrack J127 mobile jaw crusher can crush various ores, such as iron ore, copper ore, gold ore, etc. Its wide crusher feed opening and two-stage feeder design ensure high production capacity and stable material flow, making the equipment perform well in quarrying operations. In addition, the equipment is also equipped with a high-efficiency iron remover (optional) to effectively suppress dust, further improving the cleanliness and safety of the working environment.

The construction industry is another important application area for the Nordtrack J127 mobile jaw crusher. In the process of urbanization, the treatment and reuse of construction waste has become an important issue. This equipment can crush construction waste, concrete blocks, etc., and convert them into reusable aggregates, which not only solves the problem of construction waste treatment, but also realizes the recycling of resources. At the same time, the finished product has uniform particle size and good particle shape, which can meet the high-standard material requirements in the construction field.

In the metallurgical industry, the Nordtrack J127 mobile jaw crusher also plays an important role. It can crush metal ores and non-metallic ores to provide high-quality raw materials for the smelting process. The sturdy structure and efficient crushing capacity of the equipment ensure its stability and durability in harsh working environments.

In addition, Nordtrack J127 mobile jaw crusher is also widely used in the chemical industry, road construction, railway construction and hydropower station construction. In the chemical industry, it can crush various chemical raw materials and minerals to provide a suitable particle size distribution for chemical reactions. In road construction, railway construction and hydropower station construction, it can crush stones and produce the required aggregates to ensure the quality and progress of the project.

China Maxizm Mobile Jaw Crusher Nord-track J127 Advantages

Large crusher feed port and two-stage feeder

The core of the system lies in its design of a wide crusher feed port, which greatly increases the single feed volume and reduces the waiting time for material processing, thus achieving a significant improvement in production efficiency. With the two-stage feeder, materials can enter the crushing cavity more evenly and continuously, avoiding equipment overload and increased energy consumption caused by material accumulation or uneven supply, further ensuring the stability and efficiency of the production process. This design not only improves the processing capacity of the equipment, but also lays a solid foundation for achieving high productivity.

Effectively suppress dust and create a green production environment

Dust pollution has always been a major problem plaguing the industry. This equipment effectively suppresses dust flying during the crushing process by adopting advanced dust control technology. At the same time, the optional high-efficiency iron remover can automatically remove iron impurities from the material before it enters the crusher. This not only protects the crusher's cutting tools from damage, but also further reduces sparks and dust generated by metal friction, which provides better operating conditions. Provides a safer and healthier working environment for personnel.

High-volume feeder with solid structure and quick unfolding and folding

Taking into account the complexity and variability of the field operating environment, the design of this equipment pays attention to the robustness and portability of the structure. The large-volume feeder adopts a simple and fast unfolding and folding mechanism, allowing the equipment to be deployed or evacuated in a short time, greatly improving the flexibility and efficiency of on-site operations. In addition, the sturdy structural design ensures stable operation of the equipment under harsh working conditions and extends its service life.

Flexible mobility, energy saving and emission reduction

In order to further enhance the on-site adaptability of the equipment, the system is equipped with hydraulic telescopic side conveyors, which can adjust the conveying distance and angle according to actual needs to achieve flexible transfer of materials. At the same time, the energy-saving engine used effectively reduces fuel consumption and emissions while ensuring strong power, which meets the requirements of modern industry for environmental protection and energy saving. This design not only improves the overall efficiency of the equipment, but also brings significant economic and social benefits to the enterprise.

China Maxizm Mobile Jaw Crusher Nord-track J127 Principle

The belt and pulley driven by the motor, through the action of the eccentric shaft, make the movable jaw perform up and down reciprocating motion. During the rising process of the movable jaw, the angle between the toggle plate and the movable jaw increases, pushing the movable jaw plate close to the fixed jaw plate, and implementing multiple crushing mechanisms including extrusion, friction and rolling on the material. When the movable jaw descends, the angle between the toggle plate and the movable jaw decreases, and the movable jaw plate retreats under the elastic force of the pull rod and the spring, leaving the fixed jaw plate, making way for the crushed material to be discharged from the bottom outlet of the crusher. With the uninterrupted rotation of the motor, the movable jaw repeats this process continuously, completing the periodic operation of crushing and discharging, ensuring the continuity of production.

China Maxizm Mobile Jaw Crusher Nord-track J127 Principle Parameters

| Model | J217 | Work Type | Track-Mounted |

| Origin | Finland/China | Transport Package | Standard Package |

| After-sales Service | Field Installation, Commissioning and Training | Trademark | Liugong/Me. tso |