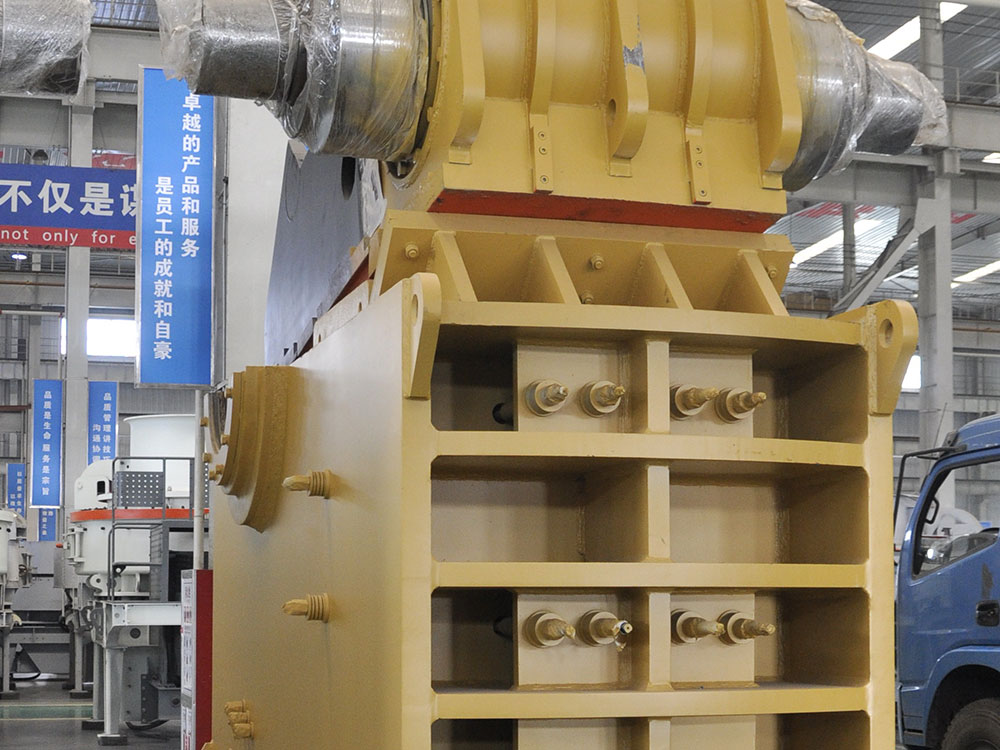

In the field of sand and gravel aggregate production, the performance and efficiency of the equipment are directly related to the overall output and economic benefits of the production line. As an upgraded version of the PFW series, the PF1314 European impact crusher has become the preferred equipment for medium and large sand and gravel production lines with its excellent design and innovative technology. Its core advantages are not only reflected in its powerful processing capabilities, but also in its flexible particle size control, efficient production capacity performance and excellent economy.

1. Large feeding capacity: a tool for handling large pieces of stone

The rotor size of the PF1314 impact crusher has reached an astonishing 1300×1150mm. This design enables it to easily handle raw materials ≤700mm, such as bluestone, limestone and other medium and low hardness materials. This means that large pieces of stone of 70 cm can be fed directly without pre-crushing, which greatly improves the processing efficiency of the production line. In practical applications, this feature enables the production line to process raw materials faster, reduce waiting time, and improve overall production capacity.

II. Particle size control: accurately meet diverse needs

Through the advanced hydraulic adjustment system, the PF1314 impact crusher can accurately adjust the gap between the impact frame and the rotor, thereby achieving flexible control of the discharge particle size. Its discharge range covers 5-40mm, and can simultaneously produce aggregates of various specifications such as 10-20mm (12 stones) and 16-31.5mm (13 stones). This fine particle size control capability enables the PF1314 impact crusher to meet the diverse needs of different customers for aggregate particle size and enhance the market competitiveness of the product.

III. Capacity performance: preferred for efficient and stable medium and large production lines

In terms of capacity, the PF1314 impact crusher also performs well. Its hourly production capacity is as high as 150-350 tons, and it is equipped with a 160kW motor, which can easily meet the needs of medium and large sand and gravel production lines. This efficient capacity performance not only improves the overall output of the production line, but also reduces the energy consumption cost per unit product, creating greater economic benefits for the company.

Technical adaptability analysis

Material adaptability: ideal choice for medium and low hardness rocks

For medium and low hardness rocks such as bluestone (hardness 2.6), the impact crushing principle of PF1314 impact crusher can give full play to its advantages. This crushing method not only has a strong crushing capacity, but also can realize the shaping function of materials during the crushing process, making the finished product particle shape more excellent, which is better than the traditional cone crusher.

Process comparison: simplify the process and save investment

The traditional sand and gravel production line usually adopts the two-stage crushing process of "jaw crusher + cone crusher". With its powerful processing capacity, PF1314 impact crusher can realize the coarse crushing-medium crushing joint operation with a single machine, which greatly simplifies the production process. This not only saves the equipment investment cost (saving more than 30%), but also reduces the floor space and staffing, and reduces the operating cost of the enterprise.

Configuration recommendation

Pretreatment requirements: ensure the quality of raw materials

If the raw materials contain a lot of soil or impurities, it is recommended to use a pre-vibrating feeder for screening to ensure the quality of the raw materials entering the impact crusher. For ultra-hard materials (such as granite), it is recommended to switch to the traditional "jaw crusher + cone crusher" solution to ensure the crushing effect and stable operation of the equipment.

Parameter optimization: balanced output ratio

By adjusting the hammer speed to 650-800r/min and controlling the gap between the impact plates to 20-30mm, the 12/13 stone output ratio can be flexibly adjusted. This parameter optimization strategy helps to meet the market demand for aggregates of different specifications and increase the added value of the product.

Maintenance points: extend equipment life

The PF1314 impact crusher adopts a heavy-duty rotor design, which extends the life of the hammer to 800-1200 hours. At the same time, the equipment supports hydraulic opening of the cover to quickly replace the hammer and other wearing parts, greatly reducing downtime and maintenance costs.

Economic evaluation

Cost comparison: a more cost-effective choice

The quotation of a single PF1314 impact crusher is about 850,000-1.2 million yuan, which is more cost-effective than the traditional "jaw crusher + cone crusher" combination (1.5 million+). This means that under the same production capacity requirements, choosing PF1314 impact crusher can save a lot of equipment investment costs for enterprises.

Energy consumption performance: a model of low-carbon and environmental protection

The power consumption per ton of PF1314 impact crusher is only 0.8-1.2kW·h, which is much lower than the 1.5kW·h of multi-stage crushing process. This low energy consumption performance not only helps to reduce the operating costs of enterprises, but also conforms to the low-carbon and environmental protection concept advocated by the current country, and helps enterprises achieve sustainable development.