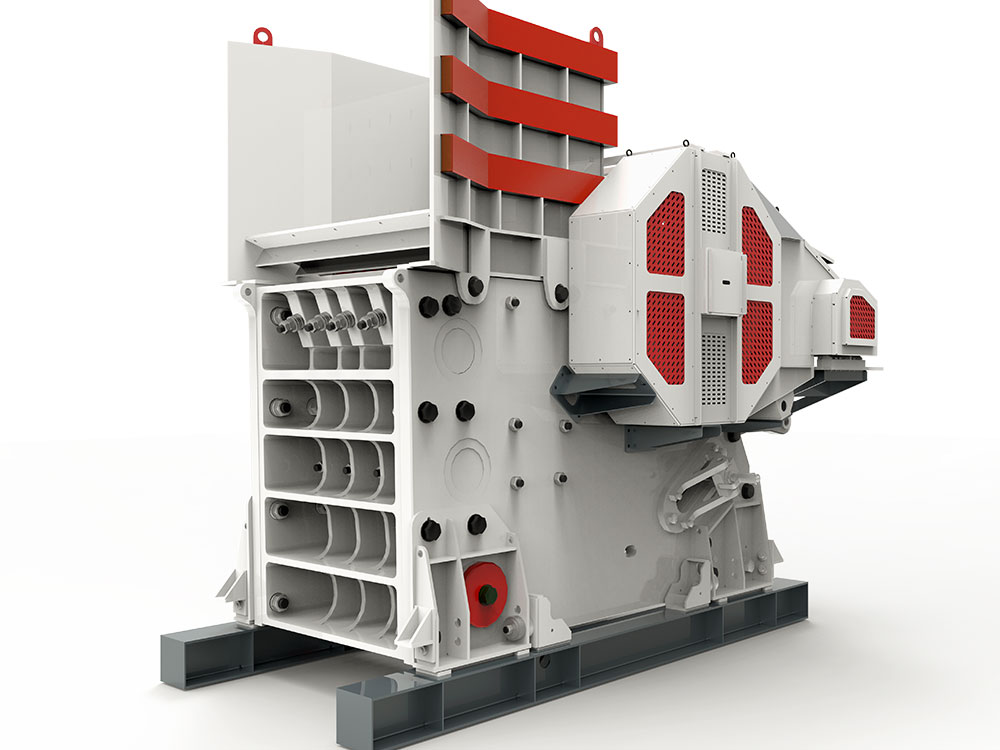

LT125 Jaw Crusher Aggregate Equipment For Sale

In the vast arena of the mining and construction industries, the crusher is the core equipment, and its comprehensive performance and operating efficiency are directly related to the smooth operation and capacity output of the entire production line. LT125 Jaw Crusher, with its excellent performance indicators, indestructible mechanical structure and extraordinary crushing efficiency, shines among many similar products and becomes a shining star in the market. Designed to cope with the challenges of high-hardness and large-volume materials, this heavy-duty crushing tool can easily handle a variety of materials from hard ores such as granite, limestone, quartz to iron ore, river pebbles, and various types of waste generated in the construction field, showing strong material adaptability.

Not only that, the processing capacity of LT125 Jaw Crusher spans from 5 tons/hour to an astonishing 2,200 tons/hour. This flexible and changeable processing capacity enables it to seamlessly connect with the diverse needs from small test lines to large industrial production lines, providing an ideal choice for production operations of all sizes. It is worth mentioning that the equipment has a high tolerance for material compressive strength, with an upper limit of 320MPa. This feature greatly broadens its application scenarios and allows it to maintain efficient and stable operation even in extreme working conditions. In summary, the LT125 Jaw Crusher is undoubtedly one of the best choices for the mining and construction industries in pursuit of efficient and reliable crushing solutions.

LT125 Jaw Crusher Applications

LT125 Jaw Crusher, as a crushing equipment that combines high efficiency and wide applicability, its application tentacles extend to many key industries, showing an influence that cannot be underestimated. Specifically:

Mining field: In this industry, LT125 Jaw Crusher plays a key role in the deep processing of ores, especially in the secondary crushing and fine crushing stages. Its excellent performance significantly improves the recycling rate of ore resources and adds to the economic benefits of mining companies. Help.

Chemical industry: Faced with the complex and diverse raw material processing needs of the chemical industry, the LT125 Jaw Crusher can easily handle the crushing tasks of various materials with its powerful crushing capacity, ensuring the smoothness and efficiency of the chemical production process.

Building materials industry: As the cornerstone of building materials production, the crushing processing of stone and concrete is crucial. With its precise crushing technology and stable operating performance, the LT125 Jaw Crusher provides solid and reliable raw material support for the building materials industry and promotes the sustainable development of the industry.

Metallurgical industry: The metallurgical process often begins with the crushing of ore. The LT125 Jaw Crusher can efficiently crush metal ores into the ideal particle size range, laying a solid foundation for subsequent smelting processes. It is one of the indispensable and important equipment in the metallurgical industry.

LT125 Jaw Crusher Advantages

Strong and durable, quality builds trust

The LT125 Jaw Crusher is built on high manganese steel, which makes it indestructible. Its core components, the jaw plate and jaw teeth, have been carefully crafted through special processes, and the hardness has jumped to between HB180 and HB220, ensuring that they can maintain a long life and peak performance under extreme working conditions. This material not only has excellent wear resistance, but also has toughness and impact resistance, making it easy to handle the crushing journey of large pieces of materials. At the same time, the equipment design cleverly incorporates the concept of rapid replacement of wearing parts, effectively reducing maintenance costs, accelerating production processes, and improving overall operational efficiency.

Fine craftsmanship, quality in details

From casting to machining, every process of the LT125 Jaw Crusher embodies the essence of advanced technology. The jaw plate and other key components have undergone fine casting and heat treatment, with accurate dimensions and a smooth surface like a mirror, which not only optimizes the crushing effect, but also greatly reduces dust pollution caused by wear. The whole machine has a scientific and reasonable structural design, tacit cooperation between components, smooth and quiet operation, and minimal noise and vibration, creating a more comfortable and healthy working environment for operators.

Intelligent control, convenient leading the future

The LT125 Jaw Crusher is equipped with an intelligent control system, allowing equipment monitoring and operation to transcend time and space boundaries. Users only need to tap the screen to understand the operating status of the equipment, master various key parameters, and respond to fault warnings in time. The intelligent system also has an automatic protection function. In case of abnormal conditions, the safety mechanism is immediately activated, the machine automatically shuts down and issues an alarm, effectively ensuring equipment safety, preventing accidents, and making production more worry-free.

Widely applicable, enabling industrial upgrading

As a leader in the industry, the LT125 Jaw Crusher shines in many fields such as mining, construction, transportation, and chemical industry with its excellent performance and wide applicability. It is not only a tool to improve production efficiency and reduce costs, but also a powerful boost to promote the rational use of resources and promote sustainable development. With the continuous growth of market demand and the continuous advancement of technological innovation, LT125 Jaw Crusher will continue to lead the industry trend and inject new vitality and impetus into the development of various industries.

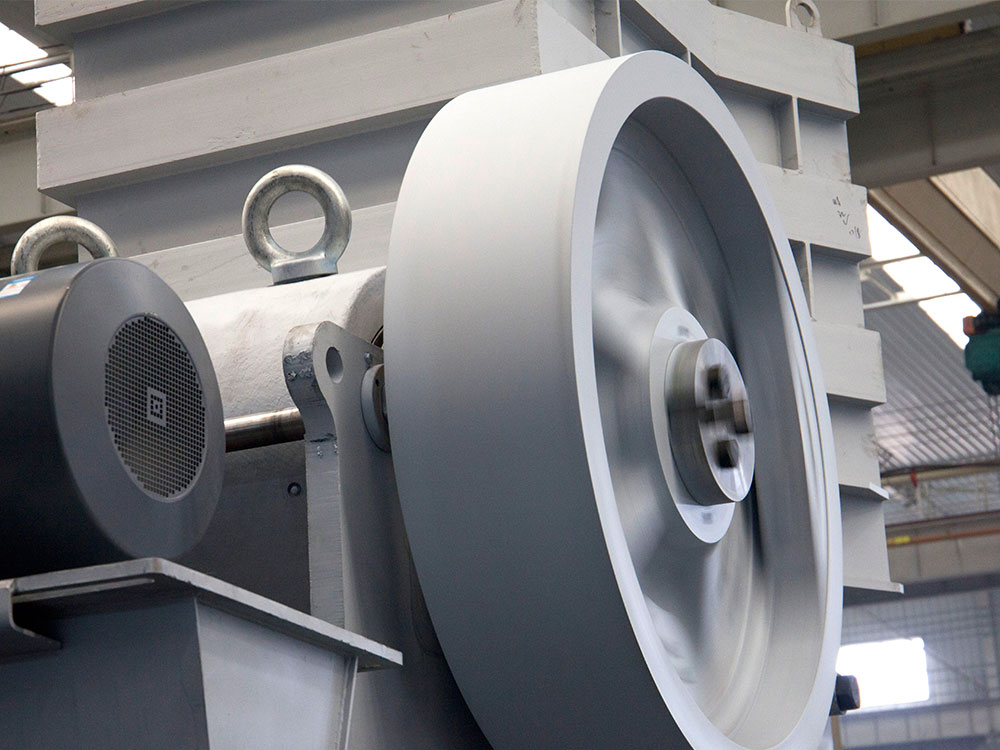

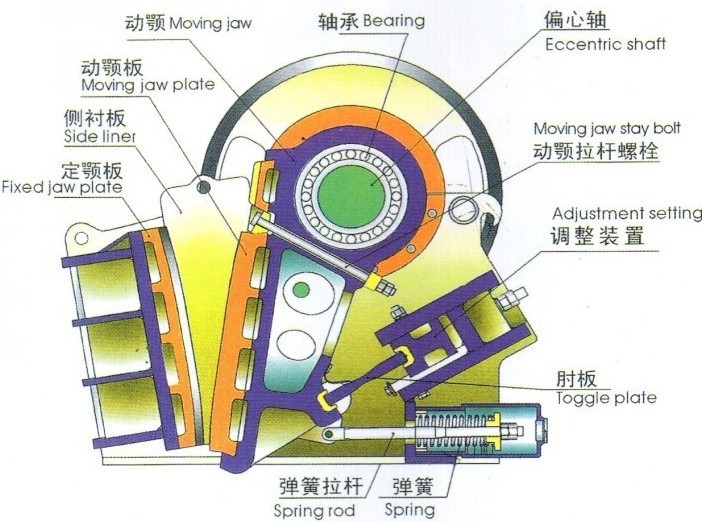

LT125 Jaw Crusher Principle

The core of the working principle of LT125 jaw crusher lies in its unique jaw plate system, which is composed of a stationary jaw plate and a movable jaw plate working together. The power comes from the motor, which drives the eccentric shaft to rotate through a belt drive, and this rotational motion is converted into the reciprocating lifting and lowering of the vertical connecting rod. During the rising stage of the connecting rod, the toggle plate acts as a medium to push the movable jaw plate closer to the stationary jaw plate, forming a strong compression space, so that the materials in the crushing chamber are quickly crushed under the combined action of extrusion force, splitting force and bending force. On the contrary, when the connecting rod descends, the movable jaw plate withdraws with the assistance of the spring and the pull rod, the discharge port expands, and the crushed materials are discharged smoothly. This process presents a cyclical working mode, that is, every time the eccentric shaft completes a circle of rotation, the first half focuses on the crushing operation, and the second half focuses on the discharge of the material, ensuring the crushing efficiency and continuity.

LT125 Jaw Crusher Technical Parameters

| Operating weight |

|

Crusher opening length | 1.25 m |

| Crusher opening width | 0.95 m | Transport width | 3.5 m |

| Plant type |

|

Drive | D/Hy |

| Silo capacity | 9 m³ | Transport height | 3.8 m |

| Transport Package | Shanky | Model series | Nordberg |