Manganese ore, as a key raw material in steel production, battery manufacturing, and chemical industries, directly impacts supply chain costs and environmental benefits through its processing efficiency. However, traditional processing models face multiple challenges including difficulties in handling low-grade ores, high energy consumption, rapid equipment wear, and complex pollution control. This paper systematically outlines the practical path for intelligent solutions by integrating typical process flows, equipment configurations, and innovative technologies.

I. Manganese Ore Processing Workflow and Core Challenges

1. Typical Processing Flow and Technical Parameters

Crushing and Screening Stage: Employing a “jaw crusher (primary crushing) + cone crusher (secondary/tertiary crushing)” combination reduces ore particle size from ≤750mm to 30-50mm. For example, the PE-750×1060 jaw crusher achieves a processing capacity of 150-220 t/h, while the HPT300 hydraulic cone crusher controls discharge particle size at 10-30 mm.

Grinding Stage: Ball mills (e.g., MQY3785) and vertical mills (LM3700) work in tandem to grind ore to 80-200 mesh. Among these, high-pressure roller mills, as new energy-efficient equipment, reduce energy consumption by 20-30% compared to traditional ball mills, making them an ideal choice for the fine grinding stage.

Beneficiation Stage: Depending on ore properties, processes include gravity separation, magnetic separation (magnetic field strength 800-1600 kA), flotation, or combined methods. For instance, an Indonesian project achieved concentrate grades of 46-50% using a “three-stage crushing + jig” process; A South African project achieved efficient beneficiation using a C6X jaw crusher + HST cone crusher + VSI6X sand maker combination.

2. Key Technical Challenges

Low-grade ore processing: Traditional methods exhibit insufficient separation efficiency for ores with manganese content below 15%, leading to resource wastage.

High Energy Consumption: Ball mill energy consumption accounts for over 30% of processing costs, necessitating urgent energy-saving technology upgrades.

Equipment Wear: Manganese ore's Mohs hardness of 5-6 reduces crusher hammer and mill liner lifespans to 60% of those for conventional ores.

Environmental pollution: Each ton of manganese sulfate produced generates 0.8-1 ton of manganese slag, which can contaminate soil and water bodies if improperly treated.

Process control complexity: Requires coordinating over 10 parameters including differential pressure (500-800 Pa), vibration values (<2 mm/s), and temperature (80-120°C), with manual operation error rates as high as 15%.

II. Core Equipment Configuration and Intelligent Upgrades

1. Crushing System Optimization

Coarse Crushing Equipment: PE-750×1060 jaw crusher with feed size ≤750mm and processing capacity of 150-220 t/h, paired with a 960×3800 vibrating feeder for uniform material supply.

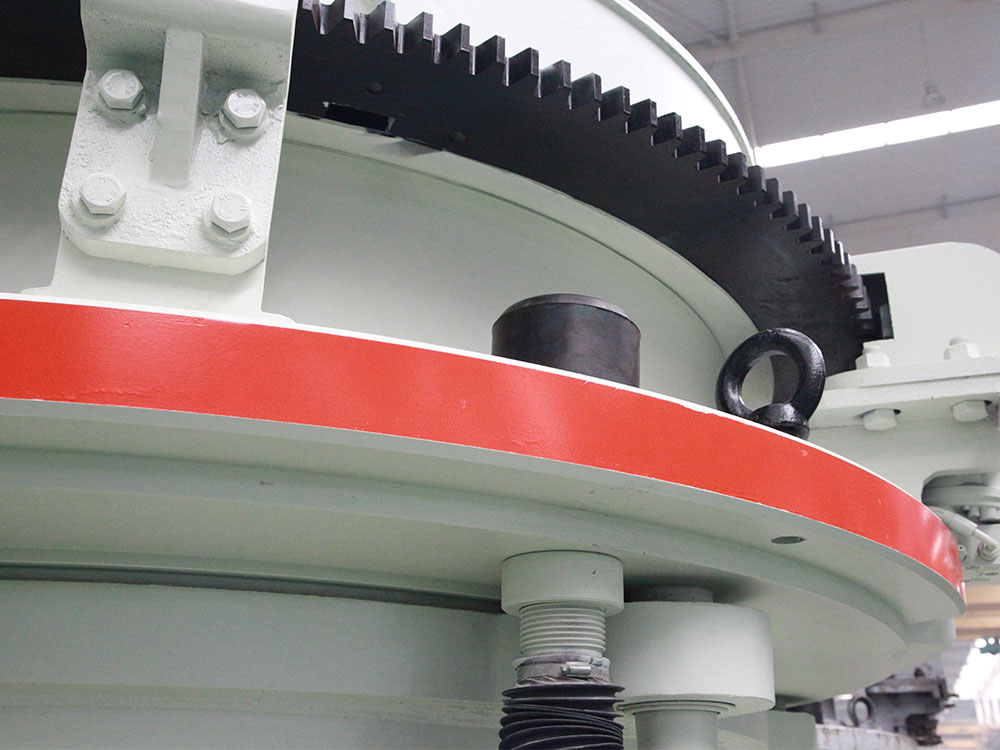

Medium-Fine Crushing Equipment: HPT300 hydraulic cone crusher with discharge size 10-30mm and processing capacity 80-150t/h, forming a closed-loop screening system with a 2500×8000 circular vibrating screen.

Innovative Application: The mobile crushing station features a modular design, reducing installation time by 50% and adapting to complex mining terrains.

2. Innovation in Grinding and Classification System

Ball Mill: MQY3785 overflow ball mill with a capacity of 80-120 t/h, paired with a 2400×9000 spiral classifier to form a closed-circuit system, boosting grinding efficiency by 20%.

Vertical Mill: The LM3700 model is suitable for fine powder processing, with a capacity of 15-30 t/h. Product fineness can reach 80% at -200 mesh.

High-Pressure Roller Mill: Utilizing the principle of laminar crushing, energy consumption is reduced by 25% compared to traditional ball mills, and over-grinding is reduced by 30%.

3. Mineral Processing Equipment Upgrades

Magnetic Separation Equipment: Rare earth permanent magnets boost magnetic field strength to 1.5 T, achieving 40% energy savings over traditional electromagnetic separators.

Floating Separator: Micro-bubble generation technology increases recovery rates for fine-grained manganese minerals by 10-15%.

Combined Process: Multi-metal ores utilize a “magnetic separation-flotation” integrated process, achieving manganese recovery rates exceeding 85%.

III. Analysis of Typical Production Line Cases

1. 300 t/h Configuration (Domestic Plant)

Feeding System: 960×3800 vibrating feeder + 600×600 feeding equipment combination, improving feed uniformity by 30%.

Crushing System: 2 PE600×900 jaw crushers + 2 250×1000 jaw crushers, achieving 320 t/h processing capacity.

Classification System: 2400×9000 spiral classifier achieves 75% -200 mesh particle size distribution.

Magnetic Separation System: High-intensity magnetic separator paired with a 3000×3000 agitation tank, achieving 42% concentrate grade.

2. 3,000-ton-per-day configuration (international case studies)

Indonesia Project: Employed a three-stage crushing process (“jaw crusher + cone crusher + fine crusher”) combined with jigging equipment, achieving 46-50% concentrate grade while reducing power consumption per ton of ore by 18%.

South Africa Project: Equipped with C6X jaw crusher, HST cone crusher, and VSI6X sand maker, reducing equipment failure rate to below 5%.

IV. Technological Development Trends and Intelligent Pathways

1. Intelligent Control Trends

DCS System Application: Automated adjustment of parameters like crushing pressure (500-800Pa) and grinding concentration (65-75%) via distributed control systems reduces manual intervention by 70%.

AI Optimization Algorithms: Neural network models trained on historical data predict equipment failures and preemptively adjust process parameters, cutting downtime by 40%.

2. Green Manufacturing Technologies

Tailings Comprehensive Utilization: Equipped with 200t/h high-efficiency thickeners, achieving 90% tailings dry-stacking rate for use as building materials or backfill.

Energy-Efficient Equipment Adoption: High-pressure roller mills, vertical mills, and other energy-saving equipment now account for 60% of installations, reducing energy consumption per unit of product by 25%.

3. Modularization and Flexible Production

Mobile Crushing Station: Integrates crushing, screening, and conveying functions, with installation and commissioning completed within 7 days to meet remote mining site demands.

Quick Die Change System: Utilizes hydraulic quick-change devices to replace different screen mesh specifications within 10 minutes, boosting product particle size adjustment efficiency by 5 times.

V. Selection Considerations and Industry Recommendations

1. Ore Type Compatibility

Manganese Oxide Ore: Prioritize spiral washing machines + vibrating screens to remove clay impurities, boosting washing efficiency by 30%.

Manganese Carbonate Ore:

Enhance fine grinding to achieve 80% -200 mesh particle size, using a closed-circuit process with vertical mills + classifiers.

Polymetallic Ore:

Recommend combined “magnetic separation-flotation” process, increasing manganese recovery by 15% compared to single-process methods.

2. Environmental and Economic Balance

Tailings Treatment: Select a high-efficiency thickener with 200 t/h capacity, paired with filter presses for water recycling, achieving 80% water savings.

Equipment Lifecycle Management: Adopt high-chromium alloy liners to extend crusher hammer life to 1200 hours, reducing maintenance costs by 40%.

3. Intelligent Upgrade Pathway

Phased Implementation: Prioritize deployment of DCS systems and online monitoring equipment, gradually introducing AI predictive maintenance modules.

Data-Driven Decision-Making: Establish digital twin models of mining operations to optimize process parameters through simulation, reducing trial-and-error costs.

The manganese ore processing industry is undergoing a transformation from “extensive” to “intelligent and green” operations. Innovative solutions like high-pressure roller milling technology, DCS control systems, and modular design effectively address challenges such as low-grade ore processing, high energy consumption, and equipment wear. Looking ahead, the integration of 5G and industrial internet technologies will enable end-to-end automation and resource efficiency in manganese ore processing, providing sustainable raw material supplies for global industries.