When it comes to equipment configuration, quartz sand plants indeed require customized design based on production capacity, raw material characteristics, and finished product requirements. This is crucial for ensuring efficient, environmentally friendly production and products that meet standards. In the following sections, we will provide a detailed overview of recommended core equipment lists, standard process flows, configuration scheme examples, and optimization suggestions for quartz sand production, offering comprehensive guidance for the industry.

I. Core Equipment Recommendation List

Core equipment plays a crucial role in the production process of a quartz sand plant. The following is a list of core equipment recommended based on typical requirements (e.g., hourly output of 100-150 tons, raw material size ≤400mm, finished product size 0-3mm fine sand):

Vibrating Feeder: As the starting point of the production line, the vibrating feeder uniformly and stably conveys raw materials to the crushing section, effectively preventing blockages and ensuring smooth operation of the production line.

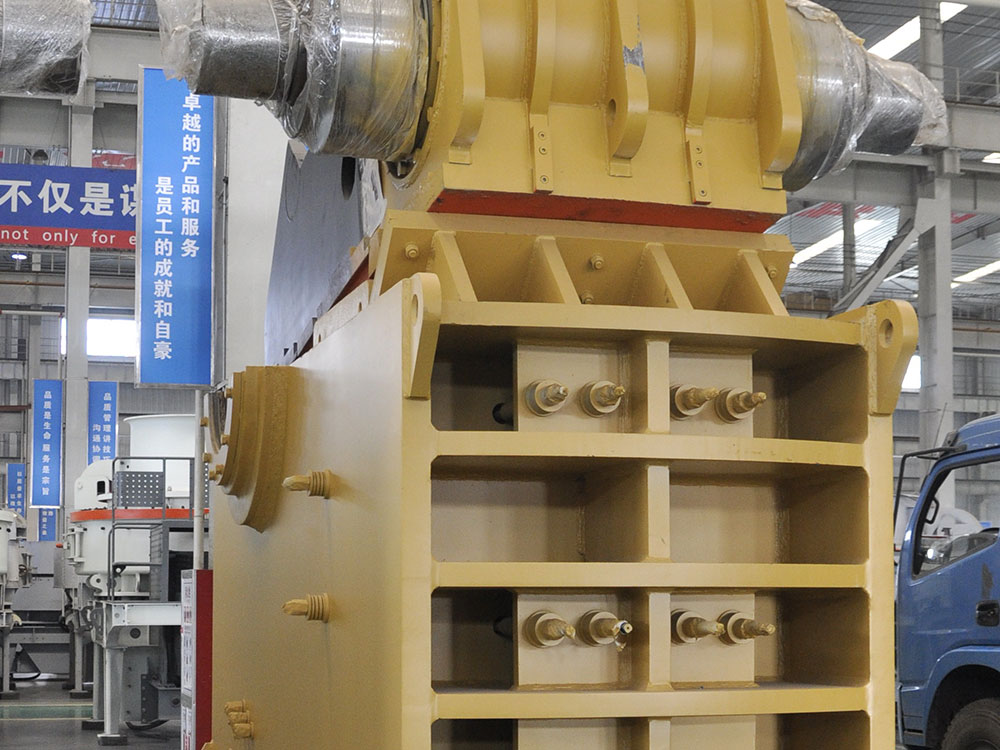

Jaw Crusher: The jaw crusher is the key equipment in the primary crushing stage, specifically designed to process large quartz stones (feed size ≤1200mm). It features strong processing capacity and high durability, quickly crushing large quartz stones into smaller particles, laying the foundation for subsequent medium crushing and sand-making stages.

Cone Crusher or Impact Crusher: In the medium crushing stage, cone crushers and impact crushers each have their advantages. Cone crushers are suitable for processing high-hardness quartz and feature overload protection to ensure stable operation; impact crushers offer high cost-effectiveness and are suitable for medium to small-scale production needs.

VSI sand-making machine: The VSI sand-making machine is a key piece of equipment for fine sand production, capable of further processing crushed quartz sand into 0-3mm fine sand with uniform particle size, fully meeting the standards for construction sand.

Vibrating screen: Vibrating screens are used for multi-stage screening, such as circular vibrating screens or linear vibrating screens, ensuring that the screened quartz sand has a reasonable particle size distribution to meet different finished product requirements.

Sand washing machine: Sand washing machines are used to remove impurities from quartz sand, such as wheel-type or spiral sand washing machines, significantly improving the purity of the finished product. Additionally, dewatering equipment can be optionally configured to further enhance the dryness of the finished product.

Auxiliary Equipment: In addition to the core equipment mentioned above, auxiliary equipment such as belt conveyors (for material transfer), dust collectors (for environmental protection control), and vibrating feeders (for process integration) must be provided to ensure the integrity and efficiency of the production line.

II. Standard Process Flow

The standard process flow of a quartz sand plant primarily includes the primary crushing stage, secondary crushing and screening stage, and sand-making and washing stage. The specific process is as follows:

Primary crushing stage: Raw materials are uniformly and stably fed into the jaw crusher via a vibrating feeder for primary crushing, reducing particles to ≤60mm, preparing them for the subsequent secondary crushing stage.

Secondary crushing and screening stage: The coarse material from the primary crushing stage is further crushed in a cone crusher or impact crusher, then screened and graded via a vibrating screen. Qualified material enters the sand-making machine for sand-making processing, while unqualified material is returned to the intermediate crushing stage for re-crushing, forming a closed-loop cycle.

Sand-making and washing stage: The sand-making machine processes the crushed quartz sand into fine sand, which is then subjected to secondary screening and washed and dewatered by the sand-washing machine, ultimately producing finished sand.

This process has a high degree of automation and supports flexible adjustments to production capacity, capable of meeting the needs of production at various scales.

3. Configuration Scheme Example (150 tons per hour)

The following is an example of a configuration scheme for a quartz sand plant with a production capacity of 150 tons per hour:

Equipment Combination: Vibrating Feeder + Jaw Crusher + Single-Cylinder Cone Crusher + Primary Vibrating Screen + VSI Sand Maker + Sand Washer

Application Scenario: Raw material particle size ≤400mm, finished product is medium-fine sand (0-3mm), fully meeting the demands of high-end markets such as glass and ceramics raw materials.

Advantages: This configuration scheme has a small footprint, low energy consumption, meets environmental standards (dust and noise control), and has controllable investment costs, offering high cost-effectiveness and market competitiveness.

IV. Optimization Recommendations

To further improve the production efficiency and product quality of the quartz sand plant, the following optimization recommendations are provided:

Production Capacity Matching: Select equipment models and quantities appropriately based on the scale and production requirements of the quartz sand plant. Small-scale plants can opt for fine jaw crushers (output ≤ 200 tons per hour), while large-scale plants can increase equipment redundancy to enhance stability.

Impurity Treatment: For raw materials with high impurity content, such as high-clay content, strengthen the sand washing process, such as using high-pressure water washing for deep cleaning. Simultaneously, integrate a recirculating water system to reduce pollution emissions and achieve green production.

Maintenance and Costs: Conduct regular inspections and maintenance of equipment to ensure stable operation and extend service life. Simultaneously, optimize production processes to shorten production cycles, reduce operational costs, and improve overall economic efficiency.

Quartz sand plants require comprehensive consideration and meticulous design in terms of equipment configuration, process flows, and optimization recommendations. By reasonably configuring core equipment, optimizing process flows, and implementing effective optimization recommendations, quartz sand plants can ensure efficient, environmentally friendly production and products that meet standards.