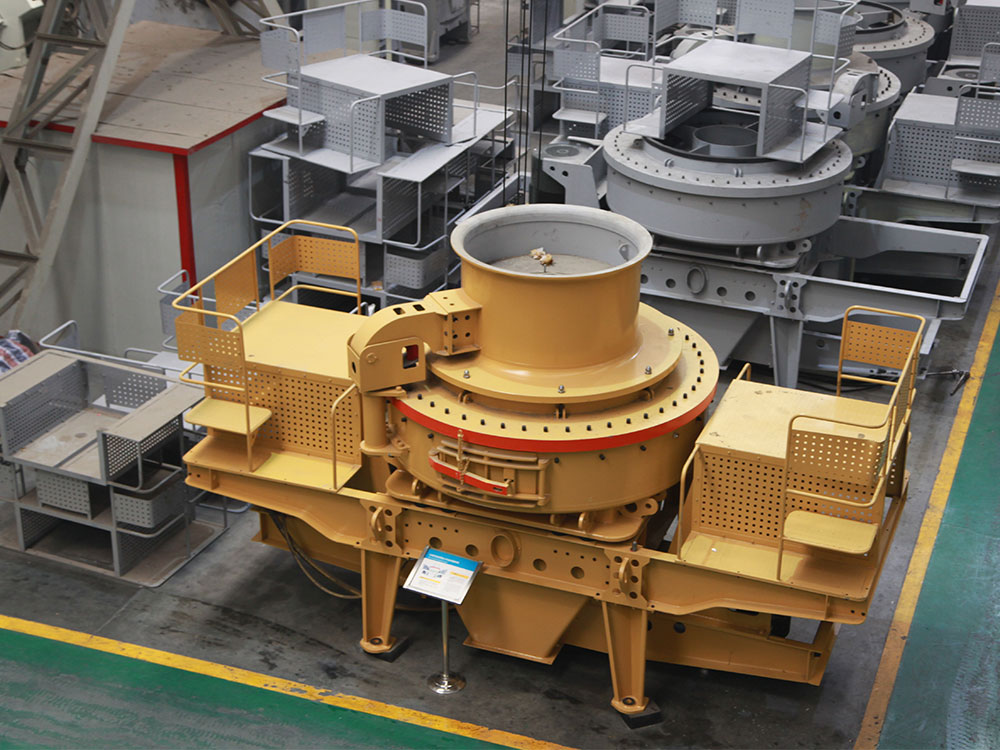

Sales of VSI-7150SE Crushers

VSI-7150SE crusher, as a leader in the industry, is designed and manufactured with the latest technological elements, and is specially designed to challenge all kinds of high hardness and abrasive materials. Through the high-speed rotor system, the machine throws the materials into the wear-resistant crushing chamber at a very high speed, and utilizes the natural impact between materials and the friction between materials and the crushing chamber wall to realize the efficient crushing and delicate shaping of materials. The VSI-7150SE is widely used in the production of sand and gravel, processing of concrete materials, crushing of metallurgical ores and other important fields. Its outstanding performance, wide range of applications, and convenient and reliable maintenance have all contributed to the VSI-7150SE's outstanding position in the market. Whether in the crushing and processing of non-metallic minerals, or in the production of concrete and the supply of construction aggregates, it can play a key role in creating greater economic benefits for users. Looking ahead, with the continuous progress of technology and the continuous expansion of the market, VSI-7150SE crusher will undoubtedly have a broader space for development and a more brilliant future.

Sales of VSI-7150SE Crushers Applications

In the core field of sand and gravel aggregate production, the VSI-7150SE crusher is the preferred choice of many producers due to its unparalleled crushing efficiency and precise particle size control technology. This equipment has demonstrated its excellent ability to handle all kinds of hardness rock materials, easily transforming them into a variety of specifications of sand and gravel aggregates that meet the requirements of national and even international high standards. These high-quality aggregates serve as indispensable cornerstones for construction, road paving, bridge building and other infrastructures, injecting strong impetus for the prosperous development of cities and building a solid material support system. the efficient operation mode of the VSI-7150SE crusher not only greatly improves the overall efficiency of the production line, but also significantly enhances the physical properties and durability of the engineering materials through the fine adjustment of the particle shape and optimization of the grading. The VSI-7150SE crusher not only greatly improves the overall efficiency of the production line, but also significantly enhances the physical properties and durability of engineering materials through fine particle shape adjustment and grade optimization. The aggregate produced by VSI-7150S not only reaches the top level of the industry in terms of particle shape and size distribution, but also in terms of mechanical strength and stability, which provides more reliable and longer-lasting building materials for various engineering projects. Therefore, VSI-7150SE crusher is not only an efficient production tool, but also a key force to promote the quality of infrastructure construction and sustainable urban development.

In the concrete products industry, the quality of aggregate, as the basic material constituting concrete, is directly related to the performance and quality of the final product. the VSI-7150SE crusher, with its unique impact crushing mechanism, has successfully set a new benchmark in the field of aggregate production. Through the fine crushing and shaping process, the machine produces high-quality aggregates with perfect particle shape and gradation, which show excellent compatibility during the concrete mixing process, and are able to combine closely with key components such as cement and water, thus significantly improving the overall strength and durability of concrete products. Not only that, the high efficiency of the VSI-7150SE crusher also greatly contributes to the improvement of production efficiency in the concrete products industry. The perfect combination of its high-speed rotor and wear-resistant crushing chamber realizes rapid crushing and shaping of materials, effectively shortens the production cycle, and reduces energy consumption and labor costs. This efficient production mode not only brings significant economic benefits to concrete product enterprises, but also injects new vigor and power into the rapid development of the whole industry. Therefore, VSI-7150SE crusher is not only a technologically advanced production equipment, but also a powerful assistant for concrete products industry to improve product quality, reduce cost and enhance competitiveness. Its wide application and promotion will surely lead the concrete products industry towards a more efficient, environmentally friendly and sustainable future.

In the vast field of metallurgical industry, ore crushing and pretreatment constitute an indispensable link in the whole production chain, and VSI-7150SE crusher plays a vital role in this link with its excellent crushing efficiency and wide material adaptability. Whether it is hard as iron ore, challenging copper ore, or other metal ores such as zinc ore, the VSI-7150SE crusher is unique in its ability to provide precise crushing control to ensure the uniformity of ore particles, which is crucial for subsequent beneficiation and smelting processes. The uniform size of the ore material not only enhances the beneficiation efficiency, but also optimizes the smelting process to ensure the quality and purity of the final product. In addition, while pursuing high production efficiency, the machine also actively responds to the call for green development. the VSI-7150SE crusher focuses on energy saving and emission reduction in its design, and significantly reduces the burden on the environment during the production process by optimizing the crushing mechanism, reducing energy consumption, and adopting effective dust control measures. This environmentally friendly feature not only helps metallurgical companies to reduce operating costs, but also helps the industry to move forward in a greener and more sustainable direction.

Sales of VSI-7150SE Crushers Advantages

Highly efficient crushing capacity

The VSI-7150SE crusher integrates the advanced impact grinding crushing principle, a technological innovation that ensures the excellent shape of the crushed material particles and meets the demand for high-precision processing. The well-designed crushing chamber structure optimizes the material flow and crushing path, which not only improves the crushing efficiency, but also significantly reduces the energy consumption and wear parts loss during the crushing process, thus realizing efficient and economical crushing operations.

Stable double-pump lubrication system

In order to ensure the continuous and efficient operation of the machine, the VSI-7150SE crusher is equipped with a stable double-pump lubrication system. The system provides sufficient and stable lubrication to all key parts of the crusher by precisely controlling the oil pressure and flow rate, which effectively reduces heat and wear caused by friction and extends the service life of the crusher. At the same time, this design improves the operational stability of the equipment and reduces breakdowns and downtime due to insufficient lubrication.

Hydraulic Pressure Jack Unit: Simplify Maintenance, Improve Efficiency

The innovative hydraulic pressure jack device of the VSI-7150SE crusher brings great convenience to the maintenance and upkeep of the equipment. The device can easily cope with the complex structure inside the equipment, enabling the operator to quickly and accurately adjust or replace wear parts, greatly shortening maintenance time and reducing maintenance costs. In addition, the smoothness of the hydraulic drive ensures safety during maintenance, further enhancing overall work efficiency.

Diverse installation and operation modes: flexible response to various needs

Considering the diversified needs of different users and scenarios, the VSI-7150SE crusher provides a variety of installation and operation modes for users to choose. This flexibility not only allows the equipment to adapt to different production environments and processes, but also reduces the technical requirements for operators, allowing more users to easily get started and efficiently utilize the equipment. Whether it is a stationary installation or a mobile operation, the VSI-7150SE crusher can be optimized to meet the production needs of users.

Sales of VSI-7150SE Crushers Principle

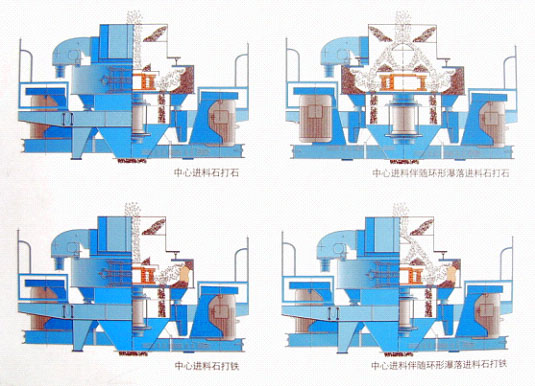

The material handling process is finely planned and executed in the VSI-7150SE crusher. Firstly, the material enters the crushing chamber through a well-designed feeding system, which usually consists of a vibrating feeder or a high-efficiency chute. They work together to ensure that the material enters the crushing area in a uniform, continuous and controlled manner, effectively avoiding overloading or clogging, and laying a good foundation for the crushing process.

Before entering the crushing chamber, some large materials may be pre-treated by the primary separation device, which separates materials that do not meet the direct processing requirements of the crushing chamber through screening technology, a step that significantly improves the subsequent crushing efficiency and effectiveness.

Once the materials enter the crushing chamber, they will immediately encounter the high-speed rotor, which is the core component of the crushing process. Under the strong action of centrifugal force, the dense distribution of throwing heads on the rotor accelerates the materials and throws them in all directions of the crushing chamber. In this process, the material and the impact plate in the crushing chamber are impacted violently, and at the same time, they are subjected to the joint action of shear force, so as to realize the preliminary crushing. Subsequently, the crushed material forms a complex eddy current movement in the crushing cavity, and the material particles impact and grind each other, after many such cycles, until it reaches the particle size range required by the user.

The wear-resistant parts of the VSI-7150SE crusher, such as the throwing head and impact plate, are the key indispensable elements in this crushing process. They are made of high-strength, high-wear-resistant materials, such as alloy steel or special alloys, to cope with the tremendous impact forces and constant wear generated during the crushing process. The performance and lifespan of the wear-resistant components are directly related to the overall operating cost and efficiency of the crusher, therefore, regular inspection, replacement and maintenance of these components are important measures to ensure the long-term stable operation of the crusher and maintain efficient output.

Finally, the fully crushed material is smoothly discharged from the crusher through the discharge system. The discharge system may be integrated with a screening device, which is capable of screening the crushed material into different particle sizes according to the user's specific needs, in order to meet the diversified market demands. The flexible adjustment of the screening device also provides users with greater operational convenience and product customization space.

Sales of VSI-7150SE Crushers Technical Parameters

| Model NO. | Barmac 7150SE | Suitable Rocks | Quartz Sand, Grit, Slag Powder, Gold |

| Surface Treatment | Sand Blast | Stock Status | Avaiable in Stock |

| Material | Cr16-Cr30nimo | Specification | Crusher Wear Parts |

| Support Models | B6150, B7150se, B9100, 760, 840, 990RO | Production Capacity | 12, 000 Mt Per Year |

| Casting Method | Water Glass Sand Casting, Lost Foam | Manufacturing Process | Casting |

| Pattern | as Per Origrinal Drawing | Color Options | Red, Blue, Green, Grey, Black. |