Against the backdrop of increasingly scarce resources and stricter environmental regulations, the resource recycling of stone waste not only yields significant economic benefits but also holds immense importance for environmental protection and sustainable development. Within the field of stone waste processing, equipment selection undoubtedly serves as the pivotal link in the entire resource recycling process, playing a decisive role.

Coarse Crushing Stage: Jaw Crusher—The “Terminator” of Large Waste Pieces

Coarse crushing is the initial step in stone waste processing, aiming to reduce large waste blocks to suitable sizes for subsequent operations. In this stage, the jaw crusher stands as the undisputed equipment of choice.

With formidable crushing capacity, the jaw crusher handles waste blocks up to 1000mm in size. Whether confronting the hardness of granite or the equally tough marble, it handles both with ease. Consider a large-scale stone processing plant that generates substantial daily waste, including oversized offcuts and defective pieces. Before adopting the jaw crusher, these large waste materials piled up like mountains, occupying vast space and proving difficult to manage. After introducing the jaw crusher, it rapidly reduced these large pieces into smaller chunks, significantly boosting waste processing efficiency. Statistics show that the plant's daily stone waste processing capacity increased by 30% after adopting the jaw crusher, providing ample raw materials for subsequent processing stages.

Medium and Fine Crushing Stage: The “Dual Champions” of Cone Crushers and Impact Crushers

Cone Crusher—The “Nemesis” of Super-Hard Materials

Entering the medium-fine crushing stage, the cone crusher demonstrates exceptional performance thanks to its meticulously designed wear-resistant liners. It efficiently processes super-hard materials like basalt and precisely controls the output particle size to within 25mm, providing high-quality raw materials for subsequent processing stages.

Basalt, an extremely hard volcanic rock, finds extensive applications in construction, road building, and other sectors. However, its high hardness poses significant processing challenges. Traditional crushing equipment often suffers from severe wear and inconsistent output particle size when handling basalt. The cone crusher effectively addresses these issues. Its wear-resistant liners, crafted from specialized materials and processes, effectively withstand basalt abrasion, extending equipment lifespan. Simultaneously, through precise adjustment and control, cone crushers can maintain output particle sizes within 25mm, meeting diverse user requirements. For instance, in a highway construction project requiring substantial quantities of basalt crushed stone for roadbed material, the project employed cone crushers for medium and fine crushing. This not only ensured the quality and particle size of the crushed stone but also enhanced production efficiency, providing robust support for the project's smooth progress.

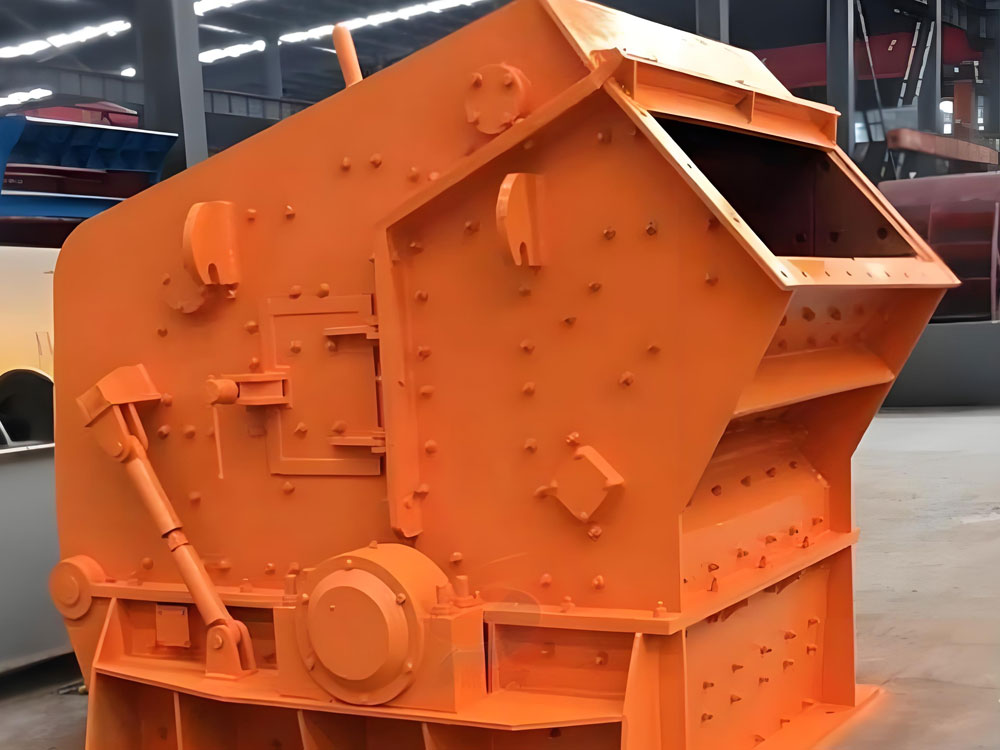

Impact Crusher—The “Shaping Specialist” for Medium-Hard Materials

For processing medium-hard materials like limestone, the impact crusher proves a more suitable choice. It produces finished products with highly uniform particle shapes, effectively enhancing product quality and boosting market competitiveness.

Limestone is a common construction material widely used in cement, glass, and other industries. It constitutes a significant proportion of stone waste in processing operations. Traditional crushing equipment often produces irregular particle shapes when processing limestone, compromising product quality. The impact crusher, however, employs a unique crushing principle that subjects limestone to multiple impacts and breaks, resulting in more uniform particle shapes. Take a cement plant as an example. Before adopting the impact crusher, the plant produced limestone aggregates with irregular particle shapes, leading to unstable cement quality. After introducing the impact crusher, the finished product's particle shape improved significantly, enhancing cement quality and greatly boosting market competitiveness. Statistics show that after using the impact crusher, the plant's cement sales increased by 20% compared to previous levels.

Sand Shaping Stage: Impact Sand Maker—The “Upgrader” for Sand Particle Quality

During the sand shaping stage, the impact sand maker plays a pivotal role. It can adjust the particle size of finished sand to below 5mm while optimizing its gradation, resulting in well-formed cubic particles. This significantly enhances the product's market competitiveness, making sand processed from stone waste more sought-after in the market.

In the construction industry, sand quality directly impacts concrete performance and project quality. Sand produced by traditional equipment often suffers from uneven particle size, unreasonable gradation, and irregular shapes, leading to unstable concrete properties. The impact sand maker achieves sand production and shaping by propelling materials through a high-speed rotating impeller, where they collide and friction against impact plates or material layers. Its unique sand-making principle ensures more uniform particle size, more rational gradation, and more regular particle shape. For instance, in a large-scale construction project requiring substantial high-quality sand as concrete raw material, the project adopted an impact sand-making machine for sand processing. The produced sand met national standards, providing robust support for the project's smooth progress. Simultaneously, the improved sand quality enhanced the strength of the concrete used in the project, reducing cement consumption and lowering overall construction costs.

Production Line Optimization Solutions: Flexible and Adaptable to Diverse Needs

Mobile Solution—The Ideal Choice for Small to Medium-Sized Projects

Production line optimization solutions offer flexible adaptability to varying production demands. Among these, the mobile solution combines a double-roll crusher with a mobile sand-making machine, making it highly suitable for small to medium-scale projects.

The mobile solution offers high flexibility and practicality, capable of being relocated to different sites for operation without complex installation or commissioning. It can process 50–150 tons of waste per hour, meeting the production demands of small to medium-sized projects. For instance, in small stone processing plants or construction sites with limited space, traditional fixed production lines cannot be installed or used. The mobile solution effectively addresses this challenge by allowing flexible positioning based on actual needs, thereby improving site utilization. Additionally, the mobile solution can adjust equipment parameters and process flows according to different material characteristics and production requirements, enabling customized production.

Environmental Design—Guardian of Green Mining

In environmental design, the mobile solution comes standard with a pulse dust collector, reducing dust emissions below 10mg/m³—fully meeting green mining standards and achieving a win-win for environmental protection and production.

Stone waste processing generates substantial dust. Without timely treatment, this not only pollutes the environment but also endangers worker health. The pulse dust collector charges dust particles via a high-voltage electric field, then uses electrostatic force to adsorb them onto collection plates, achieving efficient dust removal. Its high efficiency significantly reduces dust emission levels. Take a stone processing plant as an example: before installing pulse dust collectors, the workshop was filled with dust, requiring workers to wear protective masks. After implementation, dust concentrations dropped significantly, markedly improving the working environment. Simultaneously, the plant's dust emissions now comply with national environmental standards, avoiding penalties for pollution violations.

Equipment Maintenance—The “Guarantee” for Long-Term Stable Operation

Regarding equipment maintenance, bearings require lubrication every 200 hours, while liner plates must be inspected and replaced every 3000 hours. This ensures the equipment operates stably over the long term, providing robust support for the resource recycling of stone waste.

The normal operation of equipment relies on proper maintenance and upkeep. Bearings are one of the critical components of equipment; inadequate lubrication can lead to accelerated bearing wear, affecting the operational efficiency and lifespan of the equipment. Therefore, lubricating the bearings every 200 hours is essential. Liner plates are critical wear components in crushing equipment. They gradually wear down during operation, and once worn beyond a certain point, they impair crushing efficiency and production output. Inspecting and replacing liner plates every 3000 hours ensures the equipment remains in optimal working condition. For instance, a stone processing plant neglected equipment maintenance, resulting in severe bearing and liner wear that caused frequent breakdowns and disrupted production schedules. After implementing rigorous maintenance protocols—including timely bearing lubrication and liner inspection/replacement—the plant achieved significantly improved operational efficiency and stable production progress.

Through rational equipment selection and optimized production line planning, stone waste can be transformed into valuable resources, opening a new chapter in resource recycling. This approach not only addresses environmental challenges posed by waste accumulation but also generates substantial economic benefits for enterprises, achieving a win-win outcome for both economic and environmental gains.