Jaw crushers are essential machines in mining, construction, and recycling industries, designed to crush hard materials like rocks, ores, and concrete. However, operational challenges such as blockages can disrupt efficiency and damage equipment. If you’re wondering, “What should I do if the jaw crusher is blocked?” this article provides actionable solutions while exploring the machine’s fundamentals, applications, and technical specifications.

Understanding How a Jaw Crusher Works

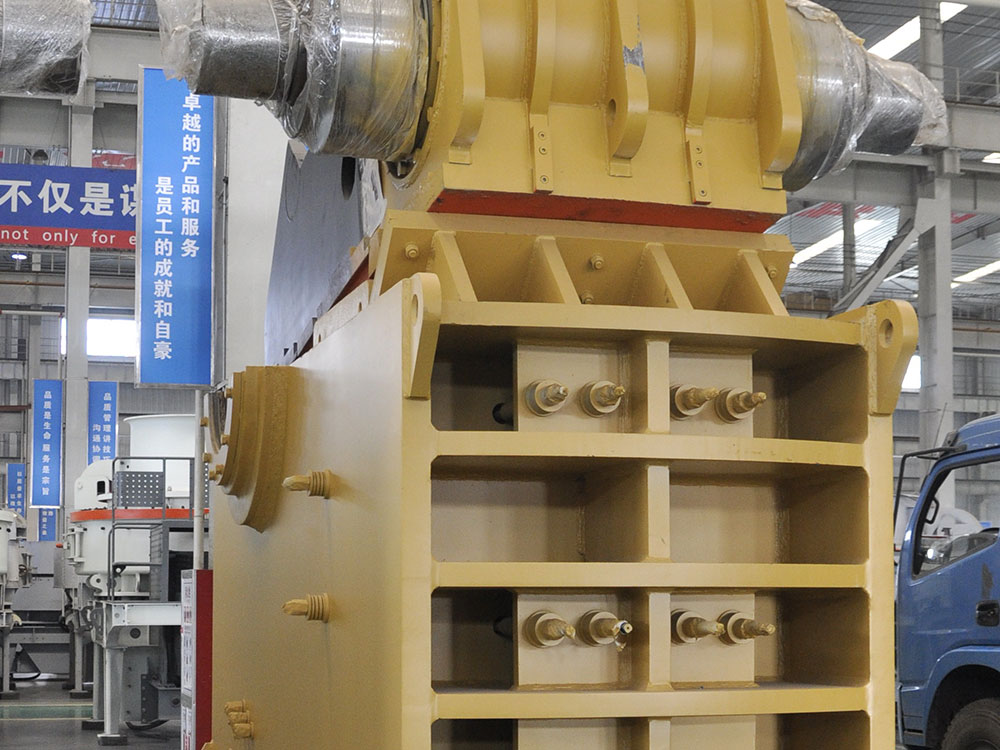

A jaw crusher operates by compressing materials between two plates: a fixed jaw and a moving jaw. The movable jaw exerts force on the material, breaking it into smaller pieces. This process relies on motor-driven eccentric shafts and toggle plates to generate the necessary crushing motion.

However, improper feeding, oversized materials, or foreign objects can lead to a blocked jaw crusher. Understanding these risks is critical to maintaining uninterrupted operations.

Common Applications of Jaw Crushers

Jaw crushers are versatile machines used in:

1. Mining: Crushing ores and minerals for processing.

2. Construction: Breaking down concrete and demolition waste.

3. Recycling: Reducing the size of materials like asphalt and bricks.

In these sectors, a jaw crusher blockage can halt production, leading to downtime and financial losses. Proper maintenance and troubleshooting are vital.

Technical Specifications of Modern Jaw Crushers

When selecting or operating a jaw crusher, consider these technical factors to minimize the risk of a blocked jaw crusher:

- Feed Opening Size: Determines maximum material size (e.g., 600x900 mm).

- Capacity: Ranges from 50 to 1,500 tons per hour, depending on model.

- Motor Power: Typically 30–200 kW, influencing crushing force.

- Adjustable Discharge: Controls final product size (10–350 mm).

Adhering to these specifications ensures efficient operation and reduces the likelihood of a jaw crusher jamming.

Why Does a Jaw Crusher Get Blocked?

1. Oversized Materials: Feeding rocks larger than the crusher’s capacity.

2. Moisture Content: Wet or sticky materials clinging to the chamber.

3. Foreign Objects: Metal debris or unbreakable items entering the crusher.

4. Wear and Tear: Worn-out jaws or plates reducing crushing efficiency.

Recognizing these issues helps preemptively address *“what to do if the jaw crusher is blocked.”*

What Should I Do If the Jaw Crusher Is Blocked?

1. Immediate Shutdown: Turn off the machine to prevent damage.

2. Inspect the Chamber: Use tools to remove visible debris.

3. Reverse the Crusher: Some models allow reversing the jaw motion to dislodge trapped materials.

4. Check the Discharge Setting: Adjust if the opening is too narrow.

5. Clean Feeders and Hoppers: Ensure no residual material causes future blockages.

For persistent jaw crusher jams, consult the manufacturer’s guidelines or a technician.

Preventing Future Jaw Crusher Blockages

1. Regular Maintenance: Lubricate parts and replace worn components.

2. Proper Feeding: Use grizzlies or screens to filter oversized materials.

3. Moisture Control: Pre-dry materials if necessary.

4. Install Safety Devices: Use metal detectors or overload protection systems.

Proactive measures significantly reduce the frequency of *“jaw crusher blocked”* scenarios.

Advanced Technologies to Minimize Blockages

Modern jaw crushers integrate features like hydraulic adjustment systems, automated overload release, and real-time monitoring sensors. These advancements help operators detect early signs of a blocked jaw crusher and take corrective actions swiftly.

For example, hydraulic toggle plates can automatically reset after encountering unbreakable objects, minimizing downtime.

Real-World Application of Troubleshooting

A mining site experienced repeated jaw crusher blockages due to clay-rich ore. By installing pre-screening equipment and adjusting the feed rate, downtime decreased by 40%. This case underscores the importance of tailored solutions when addressing *“what should I do if the jaw crusher is blocked.”*

Addressing Common Concerns About Jaw Crushers

Q: Can a blocked jaw crusher damage the motor?

A: Yes. Continuous operation during a blockage strains the motor, risking burnout. Always shut down the crusher first.

Q: How often should I inspect my jaw crusher?

A: Daily visual checks and weekly thorough inspections are recommended to prevent jaw crusher jamming.

Q: Are there tools to automate blockage detection?

A: Advanced models include IoT-enabled sensors thatalert operators to potential blockages in real time.

A blocked jaw crusher is a common but solvable challenge. By understanding the machine’s mechanics, adhering to technical specifications, and implementing preventive measures, operators can minimize disruptions. Always prioritize safety and consult experts when facing complex blockages.

Whether you’re in mining, construction, or recycling, addressing *“what should I do if the jaw crusher is blocked”* ensures optimal productivity and extends equipment lifespan. Stay proactive, and keep your operations crushing forward!