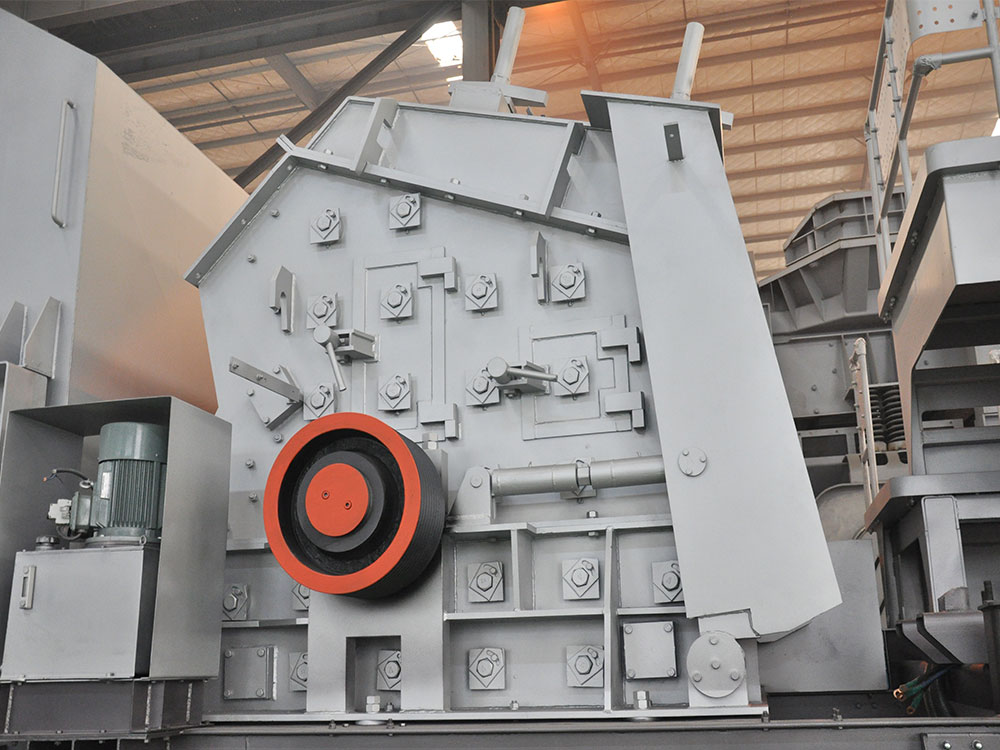

a powerful assistant for mining – C140 jaw crusher

With its powerful crushing capacity and wide applicability, the C140 jaw crusher has been widely used in many fields such as mining, metallurgy, construction and chemical industry. Whether it is hard materials like iron ore and limestone, or medium-hardness rocks like copper ore, sandstone and quartz, the C140 Jaw Crusher can easily cope with them. Meanwhile, it also plays a pivotal role in sand making, cement and refractory industries. This equipment is mainly composed of fixed jaw plate, movable jaw plate, eccentric shaft and belt and other key components, through the motor drive eccentric shaft rotation, the movable jaw plate followed by regular movement, so as to realize the effective crushing of materials. The working principle is simple and clear: the motor drives the eccentric shaft through the triangular belt and groove wheel, so that the movable jaw plate opens and closes periodically, when the movable jaw plate is close to the fixed jaw plate, the material is crushed by the strong extrusion; when the two are separated, the crushed material is discharged from the discharge opening smoothly, and the process repeats itself to ensure the continuous crushing of the material.

C140 jaw crusher Applications

The C140 Jaw Crusher excels in crushing ores and rocks of varying hardness, such as iron ore, limestone, copper ore, sandstone and quartz. The C140 Jaw Crusher, with its robust crushing components and well-designed crushing chambers, efficiently crushes these ores and rocks to the required size, providing high-quality raw materials for downstream production processes.

In addition, the C140 Jaw Crusher also plays an important role in the sand making, cement and refractory industries. In the field of sand making, it can easily crush large stones into sand that meets the needs of construction, road and other projects; in cement manufacturing, it can ensure that limestone and other raw materials are crushed to the appropriate particle size, providing a stable supply of raw materials for cement production; and in refractory manufacturing, the C140 jaw crusher can handle a variety of refractory ores and raw materials, providing high-quality crushed materials for production.

The C140 Jaw Crusher is widely used not only for its powerful crushing capacity, but also for its high flexibility and adaptability. The equipment can be customized and adjusted according to the actual needs of users to meet the crushing needs of different industries and different raw materials. At the same time, its high efficiency, energy saving and environmental protection are also in line with the development trend of modern industry, which can ensure the crushing effect while reducing energy consumption and emissions.

C140 jaw crusher Advantages

High Reliability

C140 Jaw Crusher is manufactured with high quality materials, which not only have high strength and wear resistance, but also can effectively resist fatigue and corrosion in the long-term working process. At the same time, the advanced manufacturing process ensures the precise coordination between the various parts of the equipment, which further enhances the overall stability and durability of the equipment. This highly reliable design enables the C140 Jaw Crusher to maintain long-term stable operation in harsh working environments, reducing production interruptions due to equipment failures and providing users with continuous and stable crushing capacity.

Highly efficient crushing

The C140 Jaw Crusher is known for its powerful crushing capacity. The crushing chamber inside the equipment is reasonably designed with large crushing ratio, which can quickly crush materials to the required size. Whether it is hard rock or tough minerals, the C140 Jaw Crusher can easily cope with them, realizing efficient and fast crushing operation. This efficient crushing capacity not only improves production efficiency, but also reduces energy consumption and crushing costs, creating more economic benefits for users.

Easy maintenance

The structural design of the C140 Jaw Crusher takes into full consideration the maintenance needs of users. The components of the machine are tightly connected and easy to disassemble, which makes it easy for users to carry out routine maintenance and troubleshooting, and greatly saves maintenance time and costs. In addition, the equipment is also equipped with perfect lubrication system and protective devices, which further extends the service life of the equipment and reduces the difficulty and cost of maintenance.

Strong adaptability

C140 jaw crusher can adapt to materials of different hardness and particle size, which makes it widely used in many industries. Whether it is mining, construction materials, chemical raw materials or metallurgical industry, C140 Jaw Crusher can fulfill its excellent crushing performance. This wide adaptability not only meets the needs of different industries for crushing equipment, but also provides users with more choices and flexibility.

Good Economy

During operation, C140 jaw crusher shows good economy. The equipment adopts advanced energy-saving design, which makes its energy consumption relatively low and reduces the operating cost of users. At the same time, the equipment is also easy to realize automatic control, and the intelligent control system can realize precise monitoring and adjustment of the crushing process, which improves the production efficiency and quality. This economical design not only creates more value for users, but also promotes the intelligent development of the crushing industry.

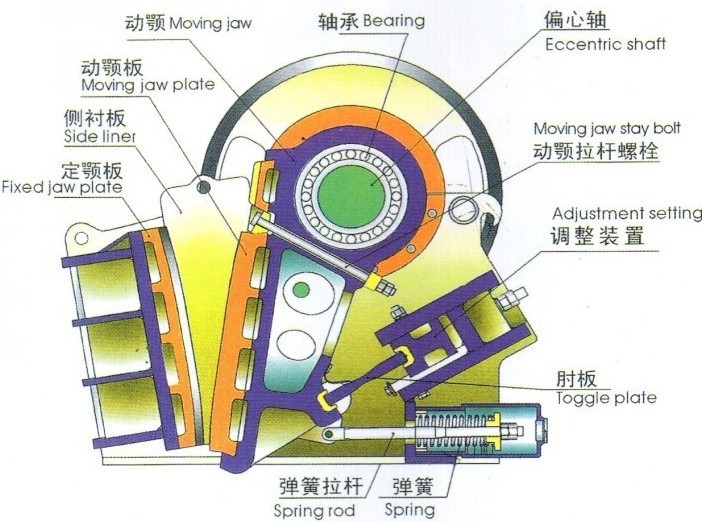

C140 jaw crusher Principle

The working principle of the C140 Jaw Crusher, though seemingly simple, actually contains a high degree of mechanical wisdom. Its core lies in the cooperative work between the motor drive system, eccentric shaft, movable jaw plate and fixed jaw plate. The motor is the power source of the whole equipment, which transmits the power to the groove wheel through the transmission device of triangle belt. The pulley further drives the eccentric shaft to rotate. This series of power transmission process not only ensures the stable transmission of power, but also effectively reduces energy consumption and mechanical wear. The rotation of the eccentric shaft drives the movable jaw plate to carry out periodic reciprocating motion. This is a key step in the crushing process. When the movable jaw plate is close to the fixed jaw plate, the space between the two is drastically reduced, which generates a strong squeezing pressure on the material clamped in it. This pressure is enough to crush the material into smaller particles. When the movable jaw plate leaves the fixed jaw plate, the crushed material has enough space to be discharged smoothly from the discharge port. This process is not a one-time event, but is repeated continuously. The motor drive system continuously provides power to the eccentric shaft, and the movable jaw plate continuously carries out the reciprocating motion of approaching and leaving the fixed jaw plate. This cyclical crushing process ensures that the material can be crushed continuously and evenly, thus greatly improving the crushing efficiency.This working principle of the C140 Jaw Crusher is not only simple and easy to understand, but also shows high efficiency in practical application. It is capable of handling materials of various hardnesses and particle sizes, with uniform particle size of the crushed material and relatively low noise and vibration generated during the crushing process. In addition, due to the simple structure of the equipment, maintenance and repair are relatively convenient, further reducing the operating costs of enterprises.

C140 jaw crusher Principle Parameters

| Type | Jaw Crusher | Width | 119in |

| Crusher RPM | 220RPM | Weight | 122,600 Lbs. |

| Min/Max Discharge | 4in-10in (150mm-375mm) | Height | 156in |

| Length | 174in | Motor power | 2 x 75 kW (2 x 100 hp) |