B9100SE crusher is easy to install and maintain

B9100SE crusher, with the advanced working principle of stone hitting stone, realizes the mutual collision and self-crushing between materials, which is able to produce cubic products with uniform particle size and low water content. This machine is undoubtedly a leader in the field of fine or ultra-fine crushing, and its efficient crushing capacity has been widely proved in many fields such as construction, industrial minerals, metal minerals and so on.

The B9100SE crusher not only saves significant energy, but also boasts a low wear rate, which greatly extends the maintenance and repair intervals of the equipment, and thus improves the start-up rate. It is particularly suitable for the final crushing stage of rock, ore and mineral processing, and is capable of consistently producing high-quality aggregates, mechanized sand and the feed material required for the heap leaching process.

The B9100SE crusher is even more capable in the production of road base and top paving aggregates, concrete and asphalt aggregates. Whether in open or closed circuit operation, it can be flexibly adapted to the type of aggregate and the required specifications. Its cascade function allows operators to easily optimize capacity and power consumption, and precisely manipulate product grade and shape to meet a wide range of stringent specifications.

B9100SE crusher is easy to install and maintain Applications

The B9100SE crusher is a powerful piece of equipment that is widely used in a variety of fields such as mining, construction industry, infrastructure construction and industrial mineral processing. In mining, it can provide stable support for the feed material before the mill, and at the same time, it can easily complete the fine crushing or ultra-fine crushing of rocks and ores, creating favorable conditions for the subsequent processes.

For the construction industry, the B9100SE crusher is even more indispensable. It is capable of producing high-quality aggregates and construction materials such as mechanism sand to meet the market demand for high-quality aggregates. At the same time, the equipment is also capable of processing construction waste and waste concrete and converting them into recycled aggregates, providing strong support for the recycling of resources.

In the construction of highway, railroad, water conservancy and other infrastructure, B9100SE crusher also plays an important role. It is capable of crushing large stones into the required particle size, providing high-quality filler for roadbed filling, dam construction and other projects, which not only ensures the quality of the project, but also improves the construction progress. In addition, this equipment also performs well in the field of industrial mineral processing, its high efficient crushing capacity and precise particle size control ability, which makes it has a wide range of application prospects in this field.

The B9100SE crusher can also be used for waste recycling. Through the crushing process, it is able to transform waste metals, plastics and other wastes into valuable resources, which not only realizes the reuse of resources, but also makes a positive contribution to the cause of environmental protection.

B9100SE crusher is easy to install and maintain Advantages

Highly efficient crushing capacity

B9100SE crusher adopts the unique working principle of stone hitting stone, utilizing the feeding materials to crush themselves by colliding with each other, with high crushing efficiency and capable of producing uniform cubic granularity final products with lower water content. In addition, the machine can be equipped with metal anvil according to customer's requirements, which can improve the crushing ratio and produce finer final products.

Wide range of applications

The B9100SE crusher is suitable for a wide range of industries, including mining, construction, industrial mineral processing, metal minerals and solid waste recycling. Its highly efficient crushing capacity and precise particle size control make it widely applicable in these industries.

Energy Saving and Environmental Protection

The B9100SE crusher is energy-efficient, especially when equipped with a conventional rock-breaking crushing chamber ring, which requires less energy for the crushing circuit due to the mutual collision of rocks. In addition, the equipment tends to have a lower wear rate, which extends maintenance and repair intervals, resulting in higher start-up rates and lower operating costs.

Easy maintenance and operation

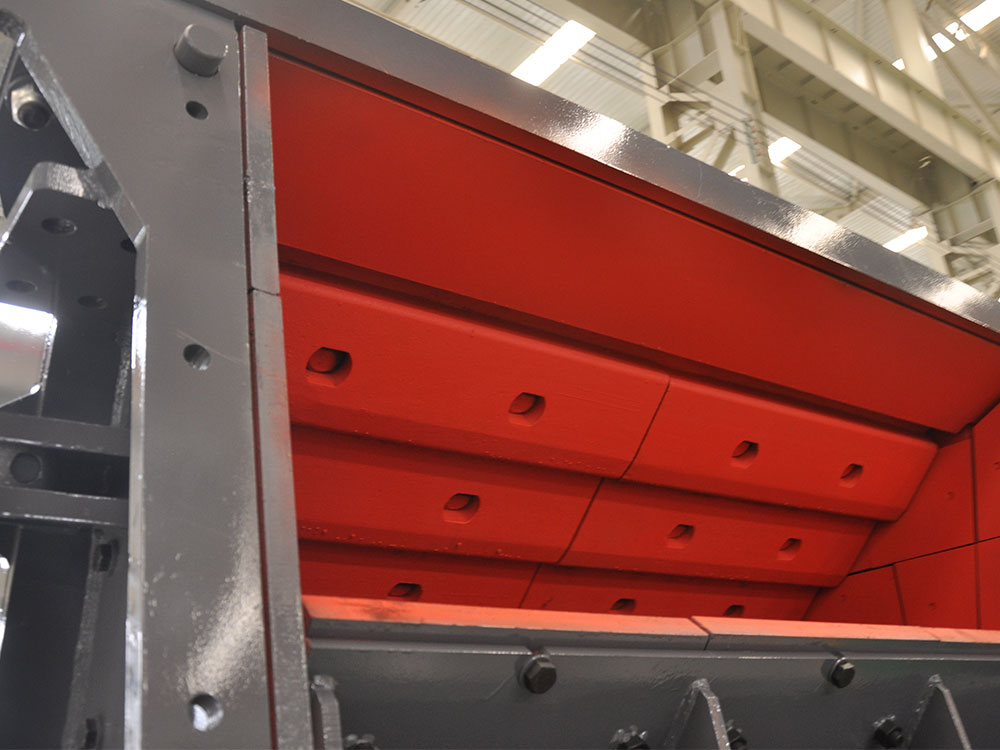

The B9100SE crusher is designed to extend the life of wear parts and increase start-up rates by reducing parts replacement times. The access door allows for quick maintenance of the rotor, drastically reducing maintenance downtime. At the same time, the machine is equipped with an automatic lubrication system for daily grease filling and lubrication of the main shaft to ensure stable operation.

Flexible Configuration and Selection

The B9100SE crusher is available in fixed, portable or mobile models to meet the needs of different customers. At the same time, the equipment can also be customized according to the customer's actual production needs, to ensure the best performance and optimized production efficiency.

B9100SE crusher is easy to install and maintain Working Principle

NW7150 Portable Impact Crusher is a machine with excellent performance. The rock-to-rock crushing process it adopts, as well as the crushing method that utilizes the feed materials themselves to collide with each other, not only improves the crushing efficiency, but also ensures the high quality of the final product. The cubic products produced by this crusher, with low moisture content and regular shape, are very suitable for use as artificial sand and other building materials. Its high efficiency, energy-saving and environmentally friendly features make it widely used in many industrial fields.

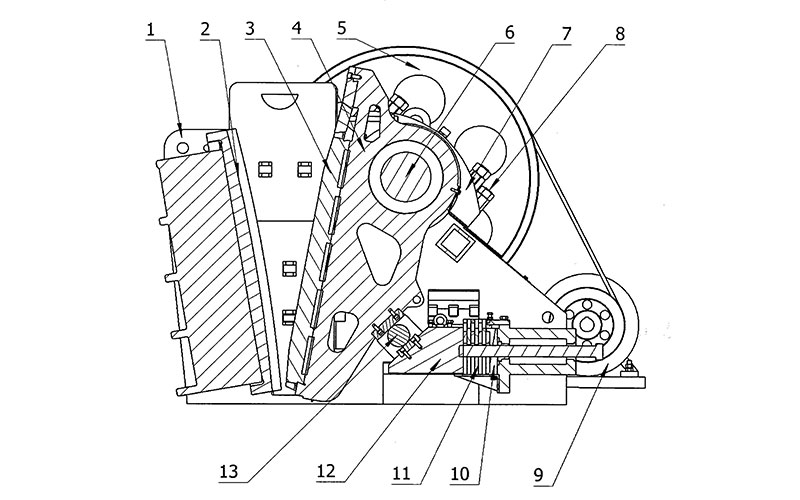

When materials enter the crusher, they will first enter the rotor. Under the high-speed rotation of the rotor, the materials are accelerated and thrown around the crushing chamber. Due to the mutual collision between the materials and the collision between the materials and the walls of the crushing chamber, the materials are quickly crushed into smaller sizes. In addition, the B9100SE crusher can be fine-tuned by changing the rotor speed or the ratio of waterfall flow to meet different production requirements.In addition to adopting the traditional working principle of stoning, the B9100SE crusher can be equipped with metal anvil iron according to the requirements of customers. In this case, the rock crushing chamber ring is replaced by an anvil iron ring, and the rock impacts act on the metal anvil iron instead of the rock stock liner. This anvil solution increases the crushing ratio and produces a finer end product, but it should be noted that abrasive materials require the anvil to be replaced from time to time, so the abrasion cost will be slightly higher.

B9100SE crusher is easy to install and maintain Technical Parameters

| Power | 320 - 600 kW | Speed | 1 000 - 1 800 rpm |

| weight | 14 400 kg | Maximum feed size | 50 mm (2”) |