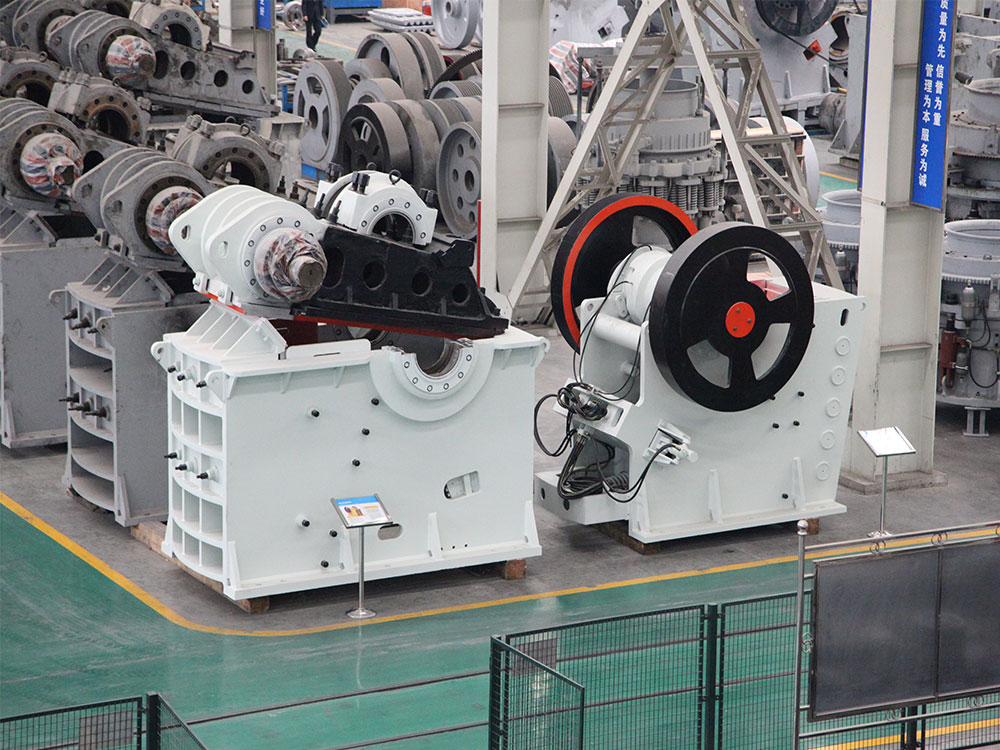

Best crushing C160 jaw crusher

The C160 Jaw Crusher is an advanced mining and processing machine designed to efficiently and reliably crush a wide range of materials in the stone industry. It represents the latest advancement in crushing technology, incorporating state-of-the-art research and development.The C160 Jaw Crusher stands out in the marketplace with its robust design and superior performance, and is the preferred choice for applications that require consistent and reliable material crushing.The C160 Jaw Crusher is available in two types of frames: welded and assembled. Welded frames are typically used on small to medium sized models, while assembled frames are used on larger models. The welded frame utilizes wide transition rounded edges, which greatly reduces stress concentrations and ensures equal strength throughout the frame. This design enhances impact resistance and reduces failure rates. The assembled frame, on the other hand, utilizes an advanced modulated and weldless frame construction design. This design provides high endurance strength and reliability, making it particularly suitable for transportation and installation in harsh environments such as underground and high altitude mines.

Best crushing C160 jaw crusher Applications

In the field of smelting processing, C160 jaw crusher also performs well. In the smelting process, the ore needs to be crushed into particles of a certain size for subsequent smelting operations, and the C160 jaw crusher, with its high crushing ratio and stable performance, ensures even crushing of the ore, providing a reliable guarantee for smelting processing.

Building materials industry is another important application field of C160 jaw crusher. In the process of building materials production, various raw materials need to be crushed into particles of a certain size to prepare various building materials.With its high efficiency and stable crushing performance, C160 Jaw Crusher ensures even crushing of building materials, and improves the quality and productivity of building materials products.

In addition, C160 Jaw Crusher also plays an important role in highway and railroad construction, water conservancy and chemical industry. In highway and railroad construction, various stones need to be crushed into particles of a certain size to prepare roadbed materials. In the field of water conservancy and chemical industry, C160 Jaw Crusher is also widely used in the crushing and processing of various raw materials, providing strong support for the development of related fields.

In the mining industry, C160 Jaw Crusher is widely used in the coarse and medium crushing operation of ores. Its simple structure and easy maintenance are especially suitable for underground mining operations. The enlarged feed opening can handle large-size ores, and the enlarged stroke at the top of the crushing chamber ensures effective crushing of ores. Meanwhile, the small meshing angle design in the middle of the crushing chamber ensures fast ore flow and improves crushing efficiency. This makes the C160 jaw crusher extremely valuable in the mining industry.

Best crushing C160 jaw crusher Advantages

The C160 Jaw Crusher excels in crushing efficiency and capacity. It is designed with efficient moving jaw movement and large eccentric distance at the bottom of the crushing chamber, which makes the crushing process more efficient. Meanwhile, the larger feed opening not only increases the feeding capacity, but also ensures that the rock enters the crushing chamber smoothly, further improving the crushing efficiency. In addition, the larger stroke amplitude at the bottom of the crushing chamber increases the capacity and crushing ratio, thus ensuring high output in a variety of operations.

The C160 Jaw Crusher also excels in durability and reliability. the C160 Jaw Crusher utilizes a pin-bolt connection and non-welded frame construction, a design that provides superior fatigue strength. All frame components are cast in alloys developed specifically for jaw crushers, further enhancing the machine's durability. In addition, critical areas of the machine are protected from wear and tear, and wear components and parts are designed to be easily accessible and replaceable, reducing maintenance costs.

The C160 Jaw Crusher is also designed with ease of operation and safety in mind. Its modular design greatly saves installation time and costs, allowing the plant to be installed in a matter of days. The plant can also be equipped with the optional IC10C automation system, which allows remote monitoring and adjustment of the feeder, crusher and conveyor settings, thus improving safety and ease of operation. In addition, the machine is equipped with safety flywheel and drive guards to protect the operator from moving parts.

The C160 Jaw Crusher also offers wide applicability and flexibility. It can handle a wide range of materials, including river pebbles, granite, basalt, iron ore, limestone, etc., and the maximum compressive strength of the crushed materials can reach 320 MPa. In addition, the equipment can be customized according to the needs of different applications to meet the specific needs of customers.

Best crushing C160 jaw crusher Working Principle

Jaw crusher adopts the crushing method of curvilinear extrusion. During the working process, the motor drives the belt and pulley to rotate, and drives the movable jaw to reciprocate up and down through the eccentric shaft. When the movable jaw rises, the angle between the elbow plate and the movable jaw gradually increases, which pushes the movable jaw plate close to the fixed jaw plate, and the materials are squeezed, rubbed and crushed between the two jaw plates, thus realizing crushing. When the movable jaw drops, the angle between the elbow plate and the movable jaw decreases, and the movable jaw plate separates from the fixed jaw plate under the action of the tie rod and the spring, at this time, the crushed material will be discharged naturally from the discharge port in the lower part of the jaw cavity under the action of gravity. With the continuous rotation of the motor, the movable jaw carries out periodic crushing and discharging action, which ensures the continuity and high efficiency of the crushing operation.

Best crushing C160 jaw crusher Technical Parameters

| Power | 250 kW (350 hp) | Operating speed | 220 rpm |

| Weight (basic unit) | 76 300 kg (168 213 lbs) | Feed opening width | 1 600 mm (63”) |

| Feed opening depth | 1 200 mm (47”) | Minimum closed side setting | 150 mm (6”) |

| Maximum closed side setting | 300 mm (12”) | non-scalped feed, maximum setting | 1 909 Mtph (2 133 Stph) |