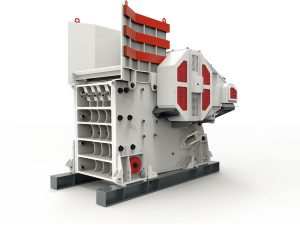

VSI sand making machine VSI crusher for quarrying

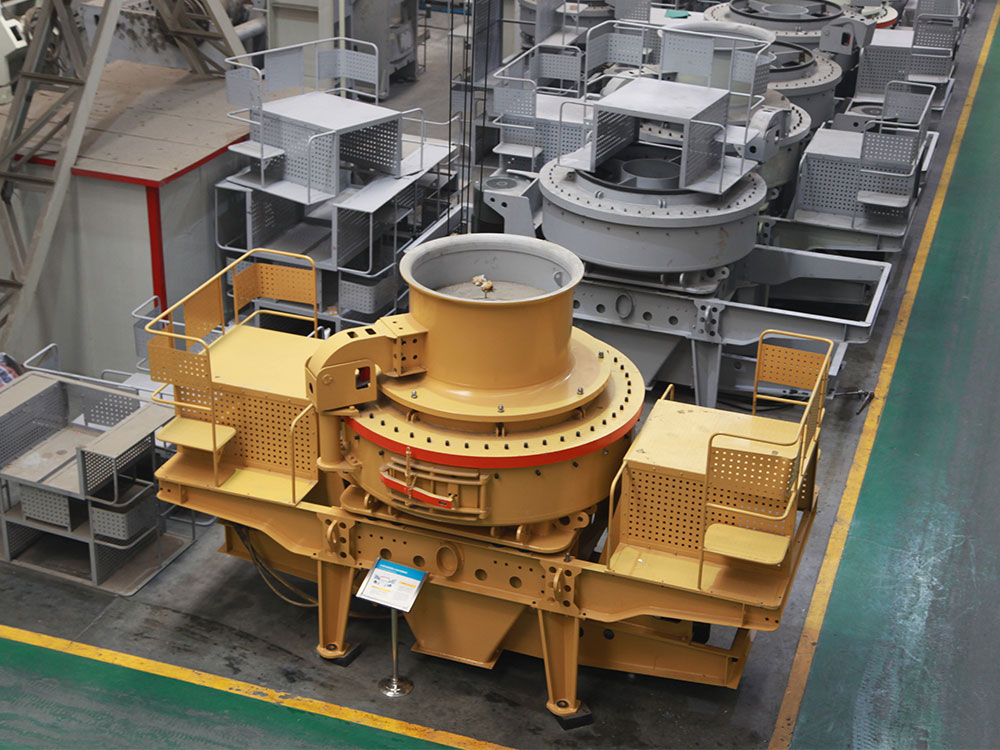

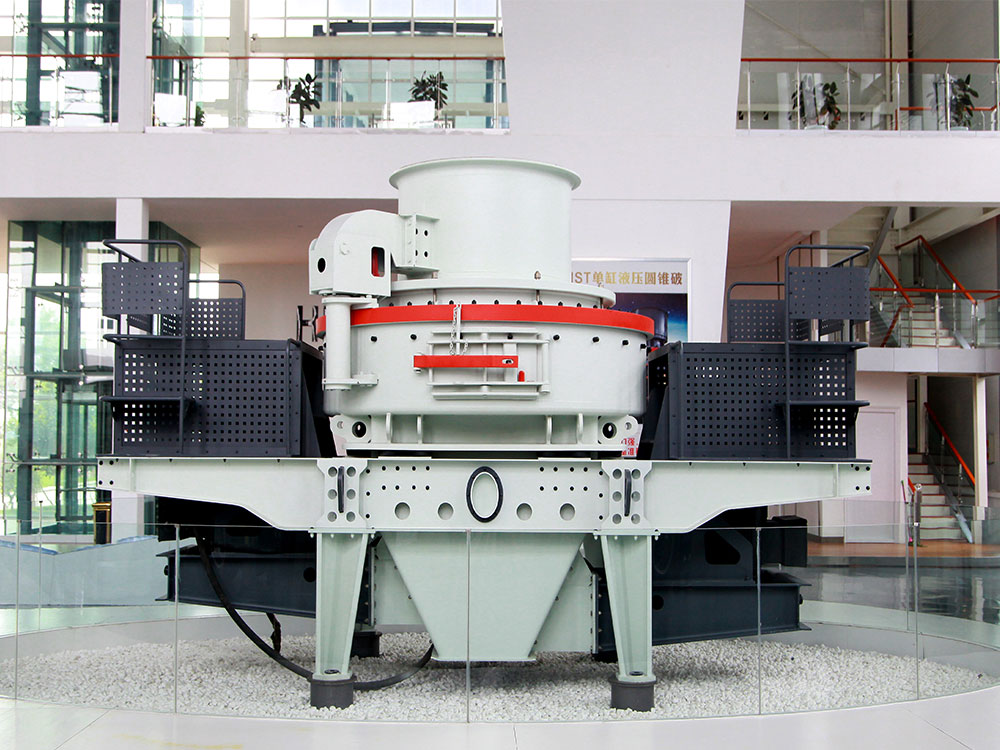

The CV215 VSI crusher is an efficient vertical impact crushing equipment specially designed to meet the production needs of high-quality sand and gravel aggregates. This equipment adopts advanced VSI technology, and through optimized rotor and crushing cavity design, it can efficiently process medium and high hardness materials, such as granite, basalt, quartz stone and river pebbles. CV215 performs well in sand and gravel crushing, fine crushing and construction aggregate production. The design focus of CV215 is to improve sand making efficiency while reducing operating costs. The equipment is equipped with high-quality wear-resistant parts, which greatly reduces wear during operation and extends the service life of core components. In addition, the automatic lubrication system and easy-maintenance structural design make the equipment easy to operate, save time and effort in daily maintenance, and significantly improve the continuity of production. In terms of performance, CV215 can process 60 to 125 tons of materials per hour. The finished product has uniform particle size and excellent particle shape, fully complying with the requirements of high-standard concrete aggregate and construction sand. The equipment also supports flexible rotor speed adjustment and feeding mode adjustment to adapt to different production needs. At the same time, CV215 has the advantages of energy conservation and environmental protection. It adopts a low energy consumption design to reduce power consumption, while effectively controlling dust and noise emissions, making it suitable for production scenarios with strict environmental requirements. Its efficiency, durability and environmental protection make it an ideal choice for mining crushing, road construction and construction projects.

VSI sand making machine VSI crusher for quarrying Advantages

Efficient sand making capability

CV215 adopts vertical impact crushing technology. The rotor and crushing chamber are carefully optimized to achieve efficient crushing and fine crushing of materials, which is suitable for producing high-standard construction sand and aggregates. The processing capacity is up to 125 tons per hour, which can easily meet the needs of large-scale production.

Excellent particle shape control

The equipment uses the principle of material self-collision and material impact lining to make the finished product particle size uniform and the particle shape excellent. It is particularly suitable for applications with high requirements for particle shape such as concrete aggregates and roadbed sand and gravel.

Low wear design

CV215 is equipped with wear-resistant materials and optimized structure, which greatly reduces the wear rate of key components, extends the service life of the equipment, and reduces the cost and time of frequent replacement of components.

Energy saving and environmental protection

The equipment adopts a low-energy consumption design, with low power demand during operation, which helps to reduce production costs. At the same time, its good dust and noise control enables it to be used in areas with strict environmental protection requirements.

Strong flexibility

Supports flexible adjustment of rotor speed and feeding method, and can be customized according to different material characteristics and production needs to ensure optimal production efficiency and sand quality.

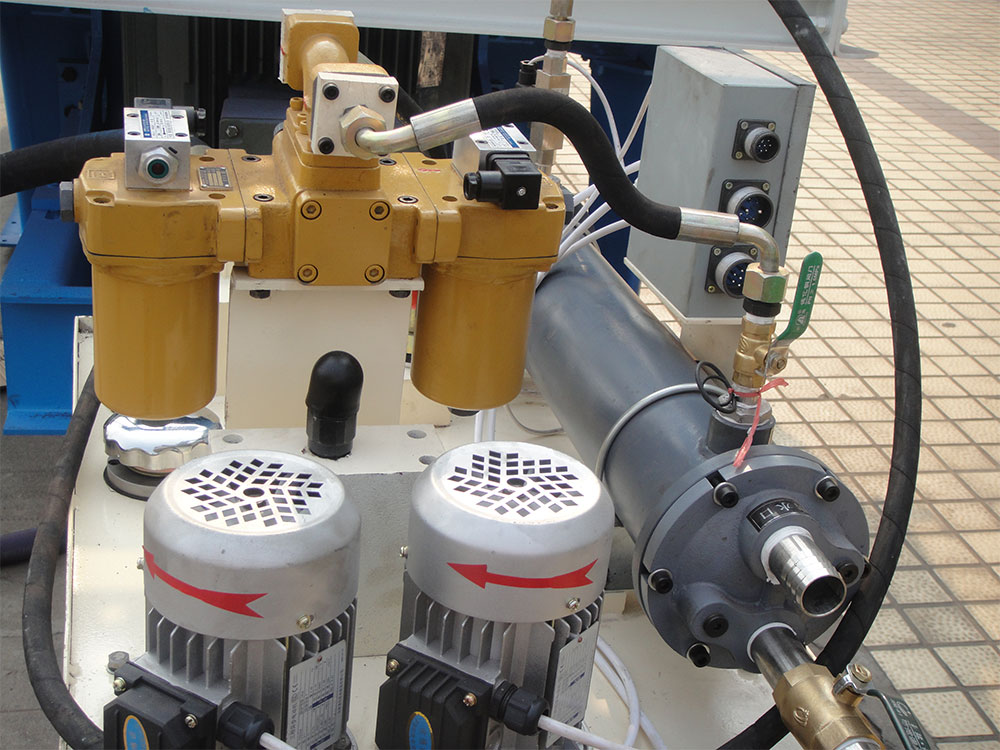

Convenient maintenance and operation

CV215 is designed with an automatic lubrication system and an easy-to-disassemble structure, which greatly simplifies the maintenance process. Daily operation is simple, without the need for cumbersome technical operators, reducing the difficulty of management.

Multi-scenario applicability

Whether it is mining crushing, construction aggregate production, or concrete mixing plants and road construction, CV215 can meet a variety of application needs with efficient and stable performance.

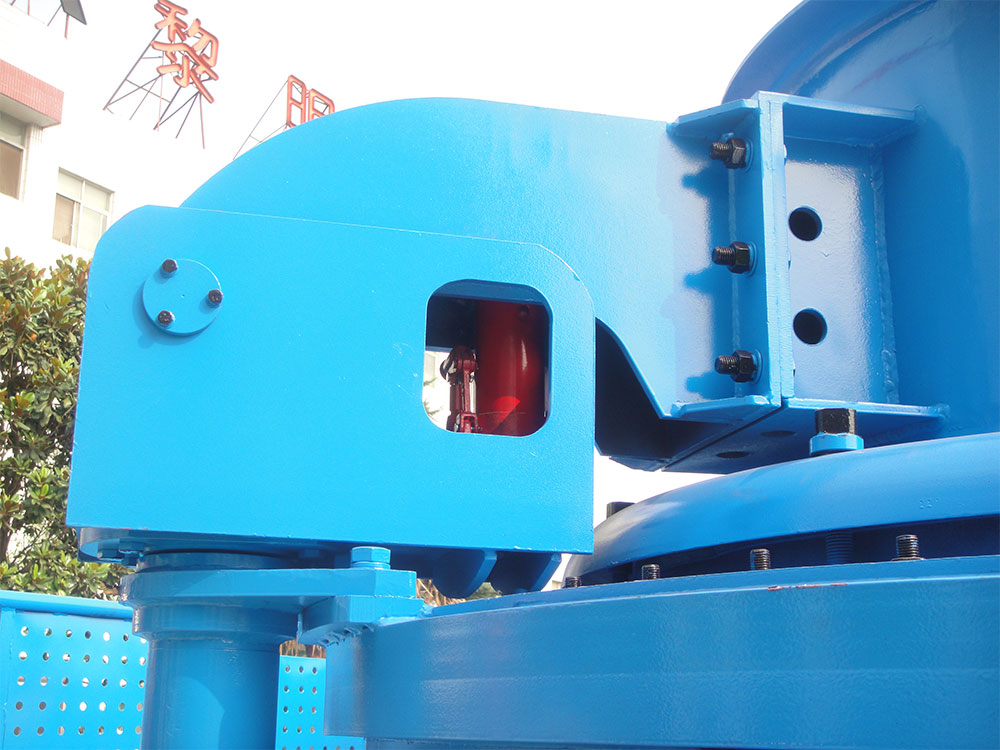

VSI sand making machine VSI crusher for quarrying Working Principle

First, the raw materials enter the high-speed rotating rotor through the feed hopper. Inside the rotor, the materials are rapidly accelerated by centrifugal force and thrown into the crushing chamber along the set trajectory at a very high speed. There are two main ways of crushing the materials in the crushing chamber: one is the mutual collision and crushing of the materials, which is called the "stone-on-stone" mode; the other is the impact and crushing of the materials and the lining of the crushing chamber, which is the "stone-on-iron" mode. The combination of these two modes can achieve efficient crushing and ensure uniform particle size and excellent particle shape of the finished product. The rotor design and crushing chamber layout of the CV215 crusher have been precisely optimized, so that the materials form a "material curtain" during high-speed movement, which not only improves crushing efficiency but also reduces wear. After multiple crushing, the materials that meet the particle size requirements are discharged from the bottom, and the non-compliant parts will continue to be circulated and crushed in the chamber until the set particle size is reached. The equipment supports flexible adjustment of the rotor speed and feeding method to adapt to different types of materials and production needs. Whether it is processing medium-hard granite and basalt, or preparing high-standard construction sand, CV215 can complete the task efficiently and show reliable sand making performance.

VSI sand making machine VSI crusher for quarrying Technical

| Output | 60-125t/h | Discharge size | 0-5mm |

| Model | CV215 | Motor power | 75-90kw |

| Feed size | 55mm | Machine weight | 5300kg |

VSI sand making machine VSI crusher for quarrying Cases and customer testimonials

Sweden is known for its high standards of building quality and sustainable development. A large local aggregate manufacturer specializes in supplying construction sand and high-quality concrete aggregates for infrastructure construction and residential development. In order to improve production efficiency and finished sand quality while reducing environmental impact, the company introduced the CV215 VSI crusher.

Project requirements

The company mainly processes hard materials such as granite and basalt, and requires equipment that can stably produce high-quality 0-5 mm fine sand while meeting environmental protection and energy-saving requirements.

Equipment performance

CV215 stably produces 80 to 120 tons of finished sand per hour, significantly improving efficiency.

The adjustable rotor speed and feeding method ensure uniform particle size and excellent particle shape, which is ideal for the high requirements of concrete and construction sand.

"Its sand production efficiency is impressive. We mainly process hard granite and basalt, and the CV215 stably produces 80 to 120 tons of finished sand per hour with uniform particle size and ideal particle shape, which is very suitable for our concrete production needs. "

"I was also pleasantly surprised by the energy-saving and environmentally friendly design of CV215. During operation, its power consumption is relatively low, it controls dust and noise very well, and it fully complies with the environmental protection standards in the area where our project is located."

"CV215 not only improves our production efficiency, but also reduces operating costs. In the production of sand and gravel aggregates, its advantages of efficiency, reliability and environmental protection are undoubtedly irreplaceable. I highly recommend this equipment to anyone who needs high quality Sand and gravel production solutions company."