C Series C110 European Jaw Crusher

Today, as the global mining and stone processing industries are booming, high-efficiency and long-life crushing equipment has become the core element to promote industry progress and enhance competitiveness. As a leader in this field, C110 European Jaw Crusher stands out among many competitors with its cutting-edge design concept and exquisite manufacturing process, becoming the preferred equipment for ore and stone crushing operations.

C110 European Jaw Crusher combines Europe's top engineering technology. From the streamlined aesthetics of the exterior to the precise construction of the internal structure, every detail demonstrates the ultimate pursuit of quality and performance. Its smooth appearance not only gives the equipment an elegant appearance, but also effectively reduces air resistance and noise pollution in actual operation, creating a quieter and more comfortable working environment for operators. The core component, the precision-cast jaw plate, is made of high-strength alloy material. After strict quality control and precision processing, it ensures the stability and efficiency of the crushing process and easily copes with the high-intensity challenges in mining operations.

In view of the hard characteristics of stone and ore, C110 specially customizes wear-resistant wedge components. These components have been specially processed to have outstanding hardness and wear resistance, as well as excellent impact and corrosion resistance, which greatly extends the service life of the equipment. Their design fully meets the needs of stone and ore crushing. Whether it is the coarse crushing of natural stone or the fine crushing of ore, they can achieve efficient and uniform crushing effects and ensure the continuous and stable operation of the production line.

In addition, the C110 European Jaw Crusher also demonstrates a high degree of flexibility and scalability. It can seamlessly connect with a variety of crusher components, such as vibrating feeders, screening devices, etc., to build a complete crushing production line to meet the personalized needs of different users. This modular design not only improves the utilization rate of the equipment, but also reduces the long-term operating costs of users, making C110 a cost-effective choice in the field of mining and stone processing.

In the crushing of ores such as iron ore, gold ore, and copper ore, as well as the processing of natural stones such as marble and granite, the C110 European Jaw Crusher has demonstrated excellent performance. Its high efficiency, stability, and durability not only improve production efficiency and reduce energy consumption, but also effectively reduce environmental pollution during the production process, contributing to the sustainable development of the enterprise. Therefore, the C110 European Jaw Crusher is undoubtedly a shining pearl in the global mining and stone processing industry, leading the industry to develop in a more efficient, environmentally friendly and sustainable direction.

C110 European Jaw Crusher Applications

In the resource-rich mining field, facing the complex and changeable types of ores and rocks, the C110 European jaw crusher has demonstrated its extraordinary crushing ability. The equipment adopts advanced crushing principles and sturdy and durable structural design, which can easily cope with ores and rocks of various hardnesses and achieve efficient crushing. This not only greatly improves the mining efficiency of the ore, but also provides high-quality raw materials for the subsequent beneficiation and smelting processes, laying a solid foundation for the production process of the entire mine. Through the precise crushing of C110, the particle size distribution of the ore is more uniform, which helps to improve the beneficiation efficiency and product quality, and create greater economic benefits for the enterprise.

In the building materials industry, the C110 European jaw crusher also plays a pivotal role. As a key equipment in the production process of building materials such as cement, aggregates, and concrete, it ensures sufficient supply and high-quality output of building materials raw materials with its efficient crushing capacity and stable operating performance. Especially in the sand making process, C110 can accurately control the crushing particle size to meet the strict requirements of different building materials products on the particle size of raw materials. Its excellent wear resistance and low failure rate have greatly reduced production costs, improved production efficiency, and promoted the sustainable and healthy development of the building materials industry.

In the wave of infrastructure construction such as roads, railways, and water conservancy, the C110 European jaw crusher also plays an irreplaceable role. The construction of these infrastructures requires a large amount of high-quality stone and aggregate as supporting materials. With its powerful crushing capacity and flexible configuration options, the C110 can quickly adapt to the needs of different construction sites and provide a steady stream of high-quality stone for infrastructure construction. Whether it is the paving of highways, the slag filling of railway tracks, or the reinforcement of embankments for water conservancy projects, the C110 provides a solid guarantee for the stability and safety of infrastructure with its excellent performance and stable performance.

C110 European Jaw Crusher Advantages

C110 European Jaw Crusher has redefined the standard of high-efficiency crushing with its innovative breakthrough in crushing technology. Through the carefully designed optimized crushing cavity and movable jaw motion trajectory, the equipment not only ensures the crushing quality, but also greatly improves the crushing efficiency and crushing ratio, effectively reducing the overall energy consumption. This ingenious design concept enables C110 to achieve higher production benefits at a lower cost when processing various ores and stones.

Wear-resistant and durable, long-lasting combat

In terms of durability, C110 also performs well. Its key components such as fixed jaw plate and movable jaw plate are made of high-strength wear-resistant materials such as high chromium and high manganese, and are treated with strict special heat treatment processes. These measures not only significantly improve the wear resistance of the components, but also greatly extend the service life of the equipment, reduce the user's maintenance cost and replacement frequency, and make C110 a veritable "long-lasting warrior" in the field of mining and stone processing.

Intelligent control, the future is here

C110 European Jaw Crusher also incorporates advanced intelligent control technology, bringing unprecedented convenience and efficiency to users. Through the intelligent control system, users can monitor the operating status of the equipment in real time, including key information such as crushing efficiency, energy consumption, and component wear. More importantly, the system supports remote monitoring and fault diagnosis functions, which can detect and solve problems in time even if you are not on site, greatly improving the reliability and maintenance efficiency of the equipment. This intelligent management method not only reduces labor costs, but also improves the overall management level of the production line.

Environmental protection and energy saving, green production

In terms of environmental protection and energy saving, C110 also spares no effort. In the design and manufacturing process of the equipment, environmental protection factors are fully considered, and low noise and low vibration design are adopted to effectively reduce noise pollution and vibration effects in the production process. At the same time, by optimizing the crushing process and energy consumption management, C110 not only reduces energy consumption, but also greatly reduces environmental pollution problems such as dust emissions. This green production method not only conforms to the sustainable development concept of modern enterprises, but also contributes to the protection of the ecological environment.

C110 European Jaw Crusher Principle

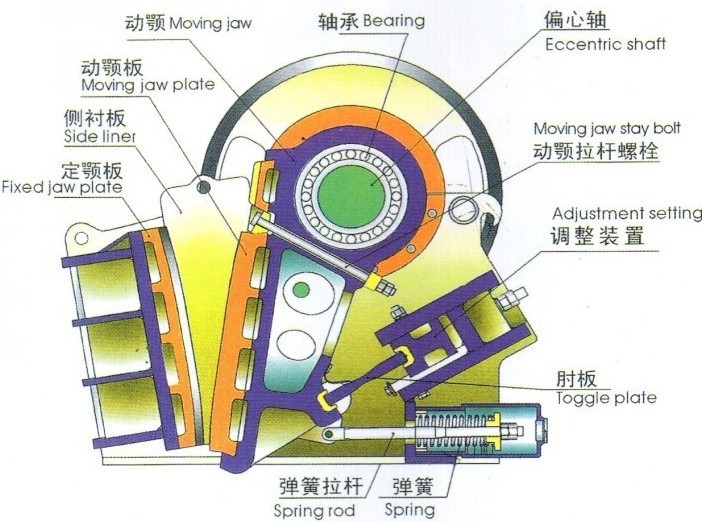

The working principle of the C110 European jaw crusher is mainly based on the relative movement of two working parts - the fixed jaw plate and the movable jaw plate. These two parts form a crushing chamber, in which the material is subjected to the combined effects of squeezing, splitting and bending to achieve crushing. When the material enters the crushing chamber through the feeding device, it is first blocked by the fixed jaw plate. At this time, the movable jaw plate is in an open state, allowing the material to enter the crushing area smoothly. As the movable jaw plate gradually approaches the fixed jaw plate driven by the eccentric shaft or hydraulic cylinder, the material is clamped between the two jaw plates. As the distance between the jaw plates decreases, the material is subjected to increasing squeezing force. At the same time, since the surface of the jaw plates is usually designed with specific crushing teeth or grooves, these structures can further split and bend the material, thereby accelerating the crushing process. When the material is crushed to a sufficiently small particle size, it will be discharged from the crushing chamber through the gap between the jaw plates. At this time, the movable jaw plate opens again to prepare for the entry of the next batch of material.

C110 European Jaw Crusher Technical Parameters

| Materials | Limestone | Transport Package | Plastic Sheet |

| Inlet Size | 32,000 kg (71,000 lbs) | Trademark | Shanky |

| Application | Construction | Outlet Size | 80-140mm |

| Condition | New | After-sales Service | All The Time |

| Origin | China | Production Capacity | 100sets |