C200 Jaw Plate Wear Parts for Jaw Crusher

The C200 jaw crusher is equipped with a spacious feed opening with a size of 1500*2000mm. It can handle feed with a maximum size of 1200mm. Its processing capacity is between 760 and 1590 tons/hour. The eccentric shaft speed reaches 200 rpm, the motor power is up to 400 kilowatts, and the overall weight is 137.16 tons. The equipment drives the movable jaw to swing forward and backward and up and down through the motor-driven belt and pulley system to crush or split the material. Under the joint action of the eccentric shaft and the spring, when the movable jaw retreats, the material is discharged smoothly from the lower discharge port of the jaw plate. The C200 jaw crusher is widely used in the crushing of various hard materials such as river pebbles, granite, iron ore, etc. It is an ideal choice for many fields such as sand and gravel yards, mining, concrete mixing plants, etc.

C200 Jaw Crusher Applications

Mining industry application: C200 jaw crusher is widely used in the mining industry. It can crush raw materials of various shapes and large sizes into materials of uniform size, providing strong support for subsequent crushing and processing processes.

Water conservancy project demand: Water conservancy projects have a huge demand for sand and gravel aggregates. As one of the important equipment for sand and gravel aggregate production, C200 jaw crusher participates in the material supply and production process of water conservancy projects, ensuring the smooth progress of the project.

Advantages in construction waste treatment: In terms of construction waste treatment, C200 jaw crusher shows its unique advantages. It can efficiently crush hard and large materials such as concrete and bricks, providing a strong guarantee for the reuse of construction waste.

Diversified application fields: In addition to the above fields, C200 jaw crusher is also widely used in many industries such as building materials, roads, railways, chemicals, etc. It can crush a variety of materials, such as pebbles, limestone, granite, etc., meeting the needs of different industries for crushing equipment.

C200 Jaw Crusher Advantages

Efficient crushing performance

The C200 jaw crusher has a powerful processing capacity, with a processing capacity between 760-1590t/h, and can efficiently complete the crushing of large amounts of materials. The 1500*2000mm feed port size allows the C200 jaw crusher to easily handle large-sized raw materials, reducing the workload of pre-treatment. The large eccentricity and larger stroke amplitude at the bottom of the crushing chamber increase the capacity and crushing ratio, ensuring high output in various operations.

Durability and reliability

The C200 jaw crusher adopts a pin-connected and non-welded frame structure, and a frame component cast from an alloy material developed specifically for jaw crushers, which has excellent fatigue resistance. Critical areas are all protected from wear, and the design of vulnerable components and parts is easy to access and replace, reducing maintenance costs. The C200 jaw crusher is modularly designed to save installation time and cost, and can be installed within a few days to minimize on-site engineering and manufacturing.

Intelligence and Automation

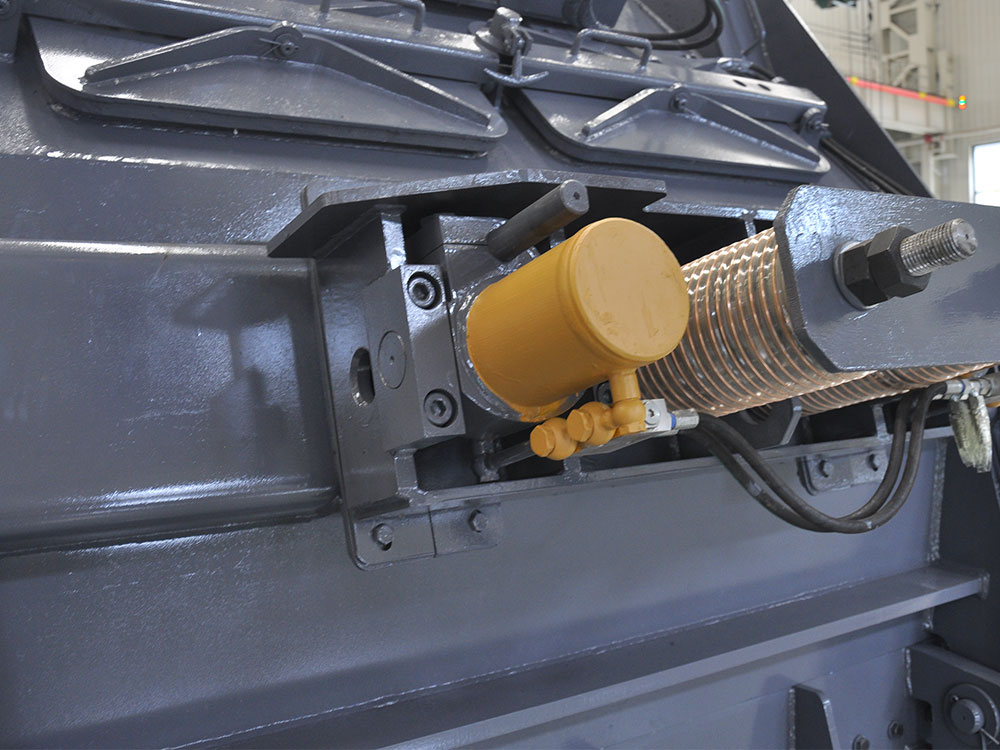

The C200 jaw crusher can be equipped with the IC10C automation system to realize remote monitoring and adjustment settings of the feeder, crusher and conveyor, making operation more convenient and safer. The C200 jaw crusher has a safe, fast and convenient discharge opening adjustment system, which can be adjusted according to different needs to meet the requirements of different users.

C200 Jaw Crusher Working Principle

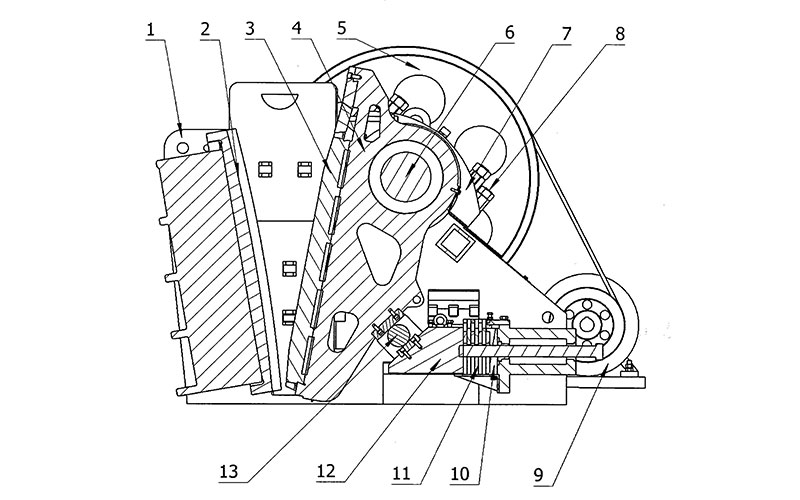

The core of the working principle of C200 jaw crusher is that the motor drives the eccentric shaft to rotate, and this rotation in turn drives the movable jaw plate to perform regular up and down reciprocating motion. The movable jaw plate is closely connected to the drive system via the eccentric shaft, ensuring the synchronization and accuracy of the movement. When the movable jaw plate swings downward, it will exert pressure on the material in the crushing chamber together with the fixed jaw plate. This continuous squeezing action causes the material to gradually split and reduce to a smaller particle size. During the whole process, the material is constantly squeezed and rubbed between the movable jaw plate and the fixed jaw plate in the crushing chamber until the desired crushing effect is achieved.

C200 Jaw Crusher Technical Parameters

| Power | 400 kW (500 hp) | Operating speed | 200 rpm |

| Weight (basic unit) | 124 000 kg (273 373 lbs) | Feed opening width | 2 000 mm (79”) |

| Feed opening depth | 1 500 mm (59”) | Minimum closed side setting | 175 mm (7”) |

| Maximum closed side setting | 300 mm (12”) | scalped feed | 1 435 Mtph (1 575 Stph) |