C80 jaw crusher aggregate equipment for sale

C80 Jaw Crusher, as an iconic high-performance crushing tool, its technical specifications demonstrate its superior strength in the crushing field. One of its core advantages is its spacious feed opening design (size up to 800X510mm), which can easily accommodate and handle large volumes of raw materials, greatly broadening the scope of material handling. The flexible and adjustable discharge particle size setting of the equipment enables it to accurately adapt to diverse production needs, from fine aggregates to coarse-grained products. The production efficiency of the C80 jaw crusher spans a wide range, from a steady output of tens of tons per hour to an efficient production capacity of hundreds of tons per hour, and the specific efficiency is adjusted according to the subtle differences in material properties and operating environment. In addition, the equipment uses AC motors as the core driving force, which not only ensures continuous stability of operation, but also achieves maximum efficiency in energy utilization, making it an indispensable heavy equipment in the construction and mining fields. It is particularly suitable for large-scale production lines of building stones, and its ease of operation further improves the efficiency and convenience of on-site operations.

C80 jaw crusher Applications

At mining sites rich in mineral resources, the C80 jaw crusher has become an indispensable equipment with its excellent performance. It integrates advanced crushing technology and durable design, and can easily cope with the challenges of various complex ores and rocks, including the hardness of iron ore, the brittleness of limestone and the diversity of granite, and efficiently crushes them to a particle size suitable for subsequent processing, providing mining companies with efficient and economical raw material solutions. In addition, the low energy consumption and low maintenance cost characteristics of C80 further help companies reduce operating costs and promote the sustainable development of the mining industry.

Faced with the problems of construction waste and waste concrete generated in the process of urbanization, the C80 jaw crusher also shows its unique value. It can convert these wastes into valuable recycled aggregates. After screening, cleaning and other process treatments, it is widely used in road construction, backfill engineering and other fields, realizing the effective reuse of construction resources, reducing environmental pressure, and promoting the green transformation of the construction industry.

In the key links of highway and railway construction, the C80 jaw crusher also plays an important role. It can precisely control the crushing particle size and produce stones that meet high standards, providing solid and reliable basic materials for road and railway subgrade filling, road paving and other construction. Its efficient and stable operation capacity not only ensures the smooth progress of the project, but also guarantees the excellence of the project quality, and makes an important contribution to the rapid development of transportation infrastructure.

C80 jaw crusher Advantages

Excellent crushing performance: Setting the benchmark for industry efficiency

The C80 jaw crusher stands out for its extraordinary high-efficiency crushing performance and has become a leader in the industry. It combines cutting-edge crushing technology with precise design optimization to ensure that the material is subjected to uniform and powerful crushing force during the crushing process, thereby achieving a double leap in crushing efficiency and particle size control. Whether it is tough rock or other challenging materials, C80 can easily crush them to an ideal state to meet the diverse needs of the market.

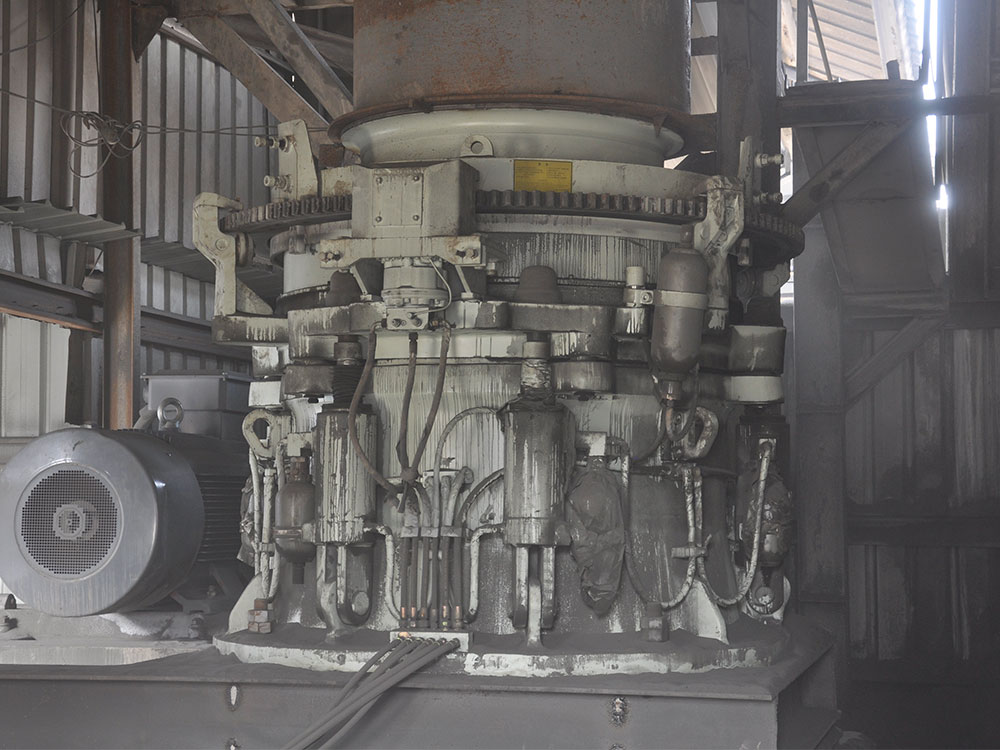

Stable and durable: Laying the foundation for long-term operation

The C80 jaw crusher pursues extreme stability and durability in structural design, selects high-quality materials and adopts precision manufacturing technology to build a solid equipment skeleton. This design not only enhances the equipment's pressure resistance and wear resistance, but also ensures its stable operation under harsh working conditions and high-intensity operations. With its excellent reliability and long life, C80 continues to create value for the company and lays a solid foundation for long-term operation.

Convenient maintenance: reduce costs, increase efficiency and increase production

In order to reduce the company's maintenance costs and improve equipment utilization, the C80 jaw crusher is designed with special attention to the convenience of maintenance. The modular design makes the equipment components tightly connected and easy to disassemble, while the replaceable wear-resistant parts and easy-to-clean crushing chamber further simplify the maintenance process. These designs not only reduce the difficulty and cost of maintenance, but also save valuable time and financial resources for enterprises, helping enterprises achieve the goal of reducing costs and increasing efficiency.

Intelligent leadership: towards a new era of automated production

In line with the development trend of the intelligent era, some high-end models of the C80 jaw crusher are equipped with an intelligent control system, opening a new chapter in automated production. The system can realize remote monitoring and automated operation of the equipment, which not only improves production efficiency but also ensures production safety. Through intelligent control, enterprises can grasp the equipment operation status and production data in real time, and flexibly adjust production strategies to quickly respond to market changes. This intelligent production method has brought unprecedented flexibility and market competitiveness to enterprises.

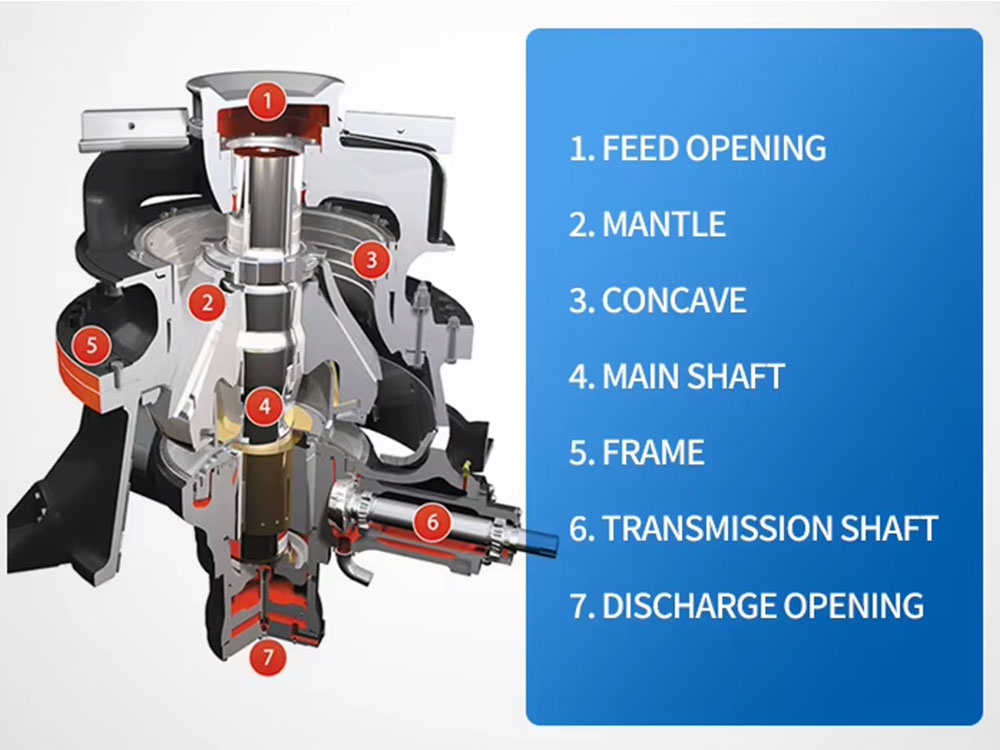

C80 jaw crusher Principle

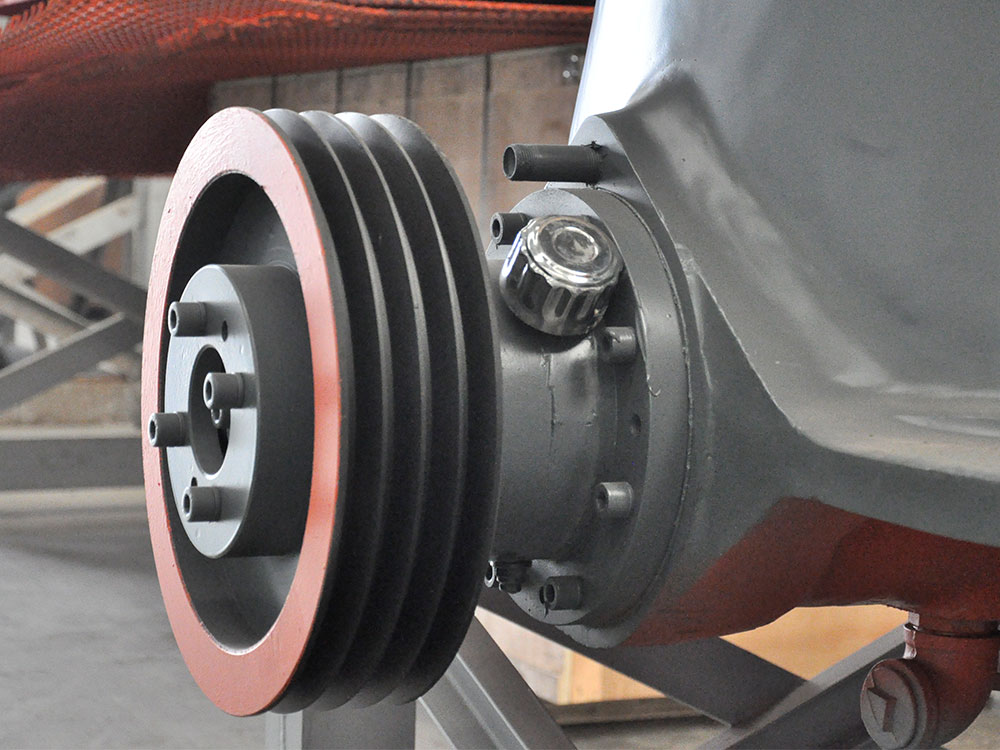

The working principle of the C80 jaw crusher is inspired by the chewing action of the two jaws of animals in nature. Through the precise mechanical structure design, it realizes efficient crushing of materials. Its core components are composed of two high-strength jaw plates, the movable jaw and the static jaw, which together constitute the crushing chamber. When the material to be crushed is fed into the crushing chamber, the movable jaw begins to play its key role.

The movable jaw is driven by a connecting rod mechanism connected to the eccentric shaft to perform periodic reciprocating motion. This motion mode not only simulates the powerful bite force in nature, but also gives the C80 jaw crusher the comprehensive crushing ability of squeezing, splitting and bending the material. As the movable jaw continues to open and close, the material is subjected to strong impact and shear force in the crushing chamber, and is gradually crushed into small pieces of the required particle size.

It is particularly worth mentioning that the C80 jaw crusher is also equipped with an adjustable discharge port design. Users can control the particle size of the crushed material by adjusting the size of the discharge port according to actual needs, so as to meet the strict requirements of different process flows on the particle size of the material.

C80 jaw crusher Technical Parameters

| Power | 75 kW (100 hp) | Weight (basic unit) | 7 650 kg (16 870 lbs) | |

| Operating speed | 350 rpm | Feed opening width | 800 mm (32”) | |

| Feed opening depth | 510 mm (20”) | Minimum closed side | 40 mm (1 5/8”) | |

| Maximum closed side setting | 175 mm (7”) |

|

514 Mtph (575 Stph) |