CH865i Cone Crusher Precise particle control and efficient crushing

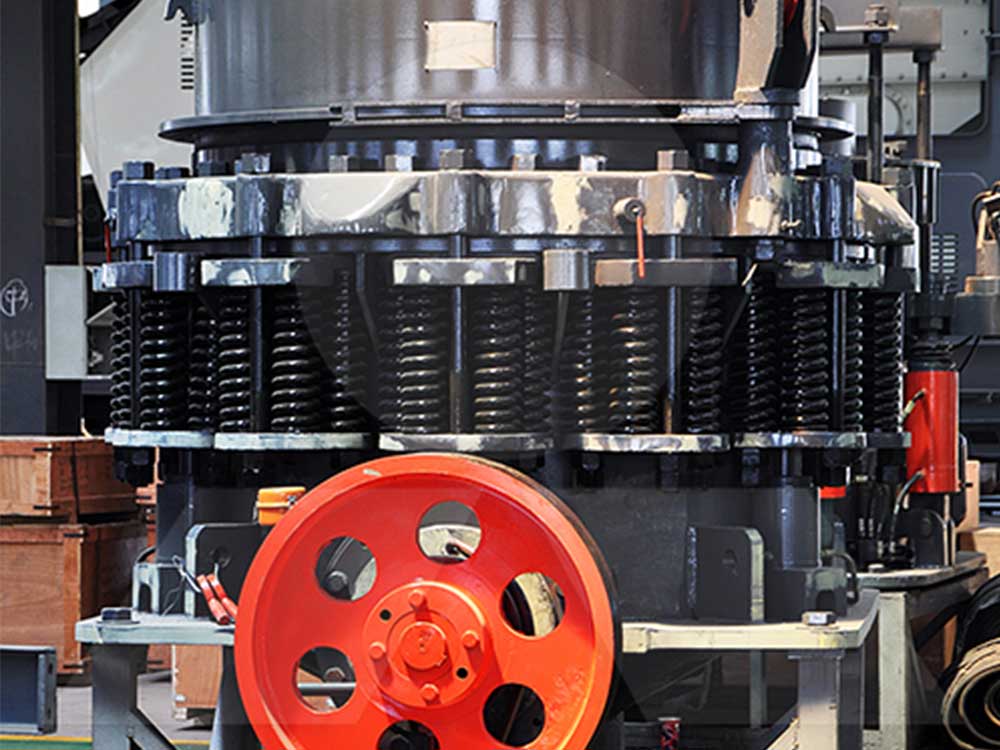

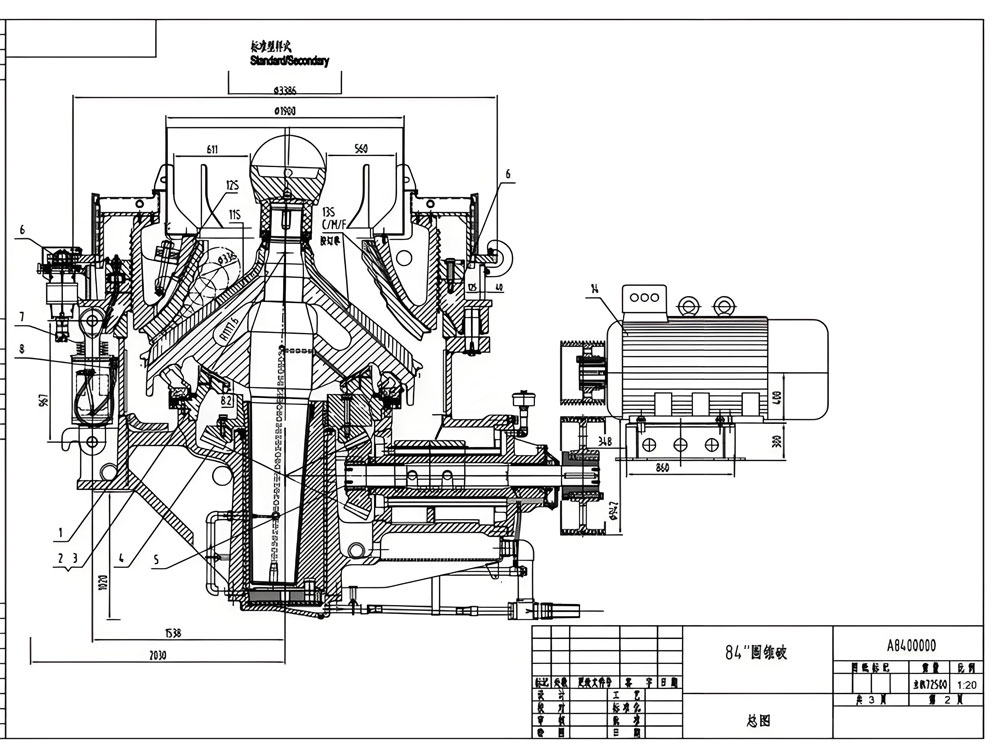

The CH865i Cone Crusher's frame is made of high strength alloy casting, which not only ensures the ruggedness of the machine, but also provides solid support for its core components such as the eccentric bushing, the dynamic cone assembly and the hydraulic lubrication system. The integration of these core components provides the machine with exceptional impact resistance and operational stability, even in the face of complex and changing operating conditions. It is particularly worth mentioning that the main shaft of CH865i Cone Crusher adopts the advanced floating support design at both ends, which makes the adjustment range of eccentricity reach 50-65mm, providing users with more flexible crushing options. Meanwhile, combined with the optimised cavity shape and thickened manganese steel liner, the machine shows higher crushing strength and durability when dealing with highly abrasive materials such as granite and iron ore.

The CH865i Cone Crusher also excels in intelligent control. Equipped with advanced hydraulic cylinder and accumulator system, it supports real-time adjustment of discharge opening (adjustment range 8-48mm), which not only improves crushing efficiency but also brings great convenience to users. In addition, when the equipment is overloaded, the hydraulic system will automatically relieve the pressure to protect the equipment from damage and effectively compensate for the change of discharge opening size caused by liner wear. What's more, the CH865i Cone Crusher also integrates intelligent monitoring devices such as temperature and pressure sensors, which can monitor the status of the bearings and lubrication system in real time. Once abnormal conditions are detected, the equipment will automatically trigger the over-iron protection and cavity clearing functions, thus effectively reducing the risk of unplanned downtime.

CH865i Cone Crusher Precise particle control and efficient crushing Applications

The demand for crushing equipment in the metal mining industry is particularly urgent, and the CH865i cone crusher, with its high crushing capacity, has become the ideal choice for processing hard ores such as iron ore, copper ore and gold ore. Its excellent crushing performance not only meets the strict requirements of the three or four-stage crushing process in mineral processing plants, but also achieves remarkable results in improving ore crushing efficiency and reducing energy consumption. The CH865i's precise discharge adjustment and optimised crushing chamber design ensures even particle size distribution of the ore, providing strong support for the subsequent beneficiation process.

In the building materials industry, the CH865i cone crusher also shows extraordinary strength. It can easily cope with the production needs of granite, basalt, limestone and other aggregates, and through the intelligent control system and advanced crushing technology, it produces highly uniform construction sand and gravel. These gravels not only meet the high standard requirements of the construction industry for the quality and performance of materials, but also play an active role in improving the service life of construction materials and reducing maintenance costs.

The demand for aggregates in the road construction sector is also significant, as the CH865i cone crusher is able to crush hard rock for road foundations and provide aggregates that meet the grading requirements. These aggregates not only have high strength and stability, but also ensure the smoothness and durability of the road. With precise crushing control and an intelligent management system, the CH865i provides an efficient and reliable solution for the production of crushed stone for road construction.

In addition, in the field of industrial solid waste recycling, the CH865i cone crusher also shows its powerful crushing ability. It is capable of recycling and crushing steel slag, refractory materials and other industrial by-products, realising the reuse of resources and sustainable development of the environment. Through the intelligent control system and optimised crushing process design, CH865i can ensure that the crushing effect and particle size distribution of these industrial by-products reach the best state, which provides strong support for the subsequent reuse of resources.

CH865i Cone Crusher Precise particle control and efficient crushing Advantages

The CH865i Cone Crusher excels in energy efficiency. Its unique combination of optimised cavity shape and high pendulum frequency design has significantly increased the processing capacity of the equipment, which is 25% higher than that of traditional equipment. At the same time, this design also effectively reduces the unit energy consumption, the energy saving effect is up to 18%, which brings significant economic benefits for users.

In terms of precise grain control, the CH865i cone crusher also shows its excellent performance. Its hydraulic system supports online adjustment of the discharge opening, allowing users to flexibly adjust the crushing granularity according to actual needs. This function not only improves the passing rate of product size up to 95%, but also provides users with more diversified crushing options.

Intelligent protection is another highlight of the CH865i Cone Crusher. The equipment integrates an advanced sensor system, which is able to monitor bearing temperature, oil pressure and other key parameters in real time. Once abnormal conditions are detected, the equipment will automatically trigger the over-iron protection and cavity clearing functions, effectively avoiding unplanned downtime due to faults and reducing users' operation and maintenance costs.

The CH865i Cone Crusher also excels in ease of maintenance. The modular design of the CH865i Cone Crusher makes the removal and replacement of the fixed cone assembly easier and faster. Users only need to spend 10 minutes to complete the replacement of the cone assembly, which greatly reduces downtime losses and improves the operating efficiency of the equipment.

The CH865i cone crusher also has excellent environmental adaptability. Its positive pressure dust protection system can effectively isolate dust and protect the interior of the machine from contamination. Meanwhile, the lubrication system of the machine is compatible with working conditions ranging from -25℃ to 50℃, which ensures the stable operation of the machine in both cold winter and hot summer. These designs not only improve the durability and reliability of the equipment, but also bring users a wider range of application options.

CH865i Cone Crusher Precise particle control and efficient crushing Working Principle

The electric motor is the power source of the CH865i Cone Crusher, which starts the rotation by driving the horizontal shaft through a V-belt. This rotational movement is transmitted by a precision designed spiral bevel gear set, which seamlessly transfers the power to the eccentric shaft sleeve. The rotary motion of the eccentric bushing is the key link in the whole crushing process, which is like a precise dancer, driving the main shaft to move periodically with a predetermined trajectory. This movement enables the moving cone to periodically approach or move away from the fixed cone liner, thus forming a continuous crushing space between the two.

When materials are fed into this crushing chamber, they will experience a fierce crushing journey. The repeated impact and grinding action of the moving cone makes the materials gradually be broken into smaller particles. These particles will gradually meet the requirements of particle size after continuous extrusion, impact and grinding. At this point, they will be smoothly discharged through the hydraulically adjusted discharge port, thus completing the whole crushing process. The hydraulic cylinder plays a vital role in the CH865i cone crusher. It can compensate for changes in the discharge opening caused by wear in real time, ensuring the continuity and stability of the crushing process. And when the equipment is overloaded, the accumulator will respond quickly to protect the equipment from damage by means of pressure relief. This design undoubtedly provides a strong guarantee for the stable operation of the equipment.

CH865i Cone Crusher Precise particle control and efficient crushing Technical Parameters

| Max. feed size | 123 mm | Capacity | 500 t/h |

| Power | 500 kW | Closed side setting (CSS) range | 10 - 44 mm |

| Eccentric throw range | 30 - 70 mm | Weight | 38,930 kg |