CH870i Cone Crusher

The CH870i cone crusher has achieved a number of major breakthroughs in design and manufacturing, ensuring its high reliability and availability under various harsh working conditions. The main shaft strength has been fully upgraded, increasing by an astonishing 65%. This improvement makes the equipment more stable when subjected to huge crushing forces, prolongs its service life, and improves crushing efficiency. In addition, the upper and lower frames of the CH870i cone crusher have also been carefully strengthened and cast optimized, with a strengthening rate of 50%. This improvement not only enhances the overall structural strength of the equipment, but also improves its wear resistance, thereby ensuring the stability and durability of the equipment in long-term operation.

In terms of maintenance, the CH870i cone crusher uses bolts to connect the arm and the fuselage liner instead of traditional welding. This innovative design greatly simplifies the maintenance process and reduces maintenance time by up to 90%. At the same time, the bolting method is also easy to replace and repair, reducing maintenance costs and improving operational safety. In addition, the CH870i cone crusher is also equipped with an advanced automatic interconnection system (ACS) as standard. This system can continuously monitor and optimize the performance of the crusher to ensure that the equipment is always in the best working condition. By automatically adjusting the settings to compensate for the wear of the crushing chamber, the ACS system can ensure the consistency of product size, thereby improving product quality and market competitiveness. The introduction of the automatic interconnection system (ACS) not only improves the intelligence level of the equipment, but also provides operators with a more convenient and efficient management method. Operators can understand the operating status and performance of the equipment in real time through remote monitoring and data analysis, identify problems in time and take corresponding measures, thereby ensuring the continuity and stability of production.

CH870i Cone Crusher Applications

In the field of ore processing, CH870i cone crusher demonstrates powerful crushing capabilities. Whether it is metal ores such as iron ore, copper ore, gold ore, or non-metallic ores such as limestone and quartzite, CH870i can easily cope with it. Its excellent crushing performance ensures that the particle size of the ore meets the requirements of subsequent beneficiation and smelting, providing high-quality raw materials for smelters.

CH870i cone crusher also plays an important role in the field of building materials. It can be used to crush stone, sand, etc. to produce high-quality aggregates and machine-made sand. These aggregates and machine-made sand are indispensable materials for construction projects such as concrete production and road paving. The precise crushing capacity of CH870i ensures uniform particle size of aggregates and machine-made sand, thereby improving the quality and durability of construction projects.

In the metallurgical industry, CH870i cone crusher also plays a key role. It is used to crush raw materials such as iron ore and coke to ensure that the particle size of the raw materials meets the requirements of blast furnace ironmaking. Through precise crushing and screening, CH870i provides a stable supply of raw materials for the metallurgical production process, ensuring the smooth progress of the production process.

At the same time, CH870i cone crusher is also widely used in chemical raw material processing. It can crush chemical raw materials such as gypsum and salt mines to meet the specific particle size requirements in chemical production. This precise particle size control provides the appropriate raw material form for subsequent chemical reactions and product manufacturing, ensuring the quality and stability of chemical products.

In addition, CH870i cone crusher also plays an important role in road and railway construction. It is used for crushing operations to provide high-quality ballast and aggregates. These materials are the basis of road and railway construction and are essential to ensure the stability and safety of infrastructure. The efficient crushing capacity and precise particle size control of CH870i provide reliable material guarantee for road and railway construction.

CH870i Cone Crusher Advantages

The CH870i cone crusher is unique in the industry for its high strength and reliability. The main shaft strength of the equipment has been fully upgraded, increasing by an astonishing 65%. This improvement makes the equipment more stable when subjected to huge crushing forces, thereby extending its service life and improving crushing efficiency. At the same time, the upper and lower frames have also been strengthened and cast by 50%, enhancing the overall structural strength of the equipment, improving wear resistance, and ensuring high reliability and longer service life of the equipment under harsh working conditions.

In terms of intelligence, the CH870i cone crusher also performs well. Through the My Sandvik portal, users can access the data generated by the equipment 24/7, which not only helps to optimize maintenance plans and extend uptime, but also significantly improves productivity. This intelligent connection and data-driven feature makes the CH870i cone crusher more competitive in a modern and digital production environment.

Efficient crushing performance is another highlight of the CH870i cone crusher. The enhanced crushing force enables the device to further reduce the material size and reduce the circulating load in the closed circuit, which is particularly suitable for tertiary, quaternary and stubborn rock crushing applications. This efficient crushing capacity not only improves production efficiency, but also reduces energy consumption and operating costs.

The CH870i cone crusher has also made innovations in terms of convenient maintenance and safety. The equipment uses bolted arms and body liners instead of welded ones. This design greatly simplifies the maintenance process and reduces maintenance time by up to 90%. At the same time, the bolting method is also convenient for replacement and repair, reducing maintenance costs and improving operational safety.

In addition, the CH870i cone crusher is also equipped with an advanced automatic interconnection system (ACS) as standard. This system can continuously monitor and optimize the performance of the crusher to ensure that the equipment is always in the best working condition. By automatically adjusting the settings to compensate for the wear of the crushing chamber, the ACS system can ensure the consistency of product size, thereby improving the quality and market competitiveness of the product. The optimization characteristics of this automated system further enhance the intelligence level and production efficiency of the CH870i cone crusher.

It is worth mentioning that the CH870i cone crusher is also extremely flexible and adaptable. The equipment provides a variety of chamber options, and users can adjust the crusher performance according to specific needs to adapt to different materials and working conditions. This flexibility enables the CH870i cone crusher to be widely used in crushing operations of various ores and rocks to meet the needs of different customers.

CH870i Cone Crusher Work Principle

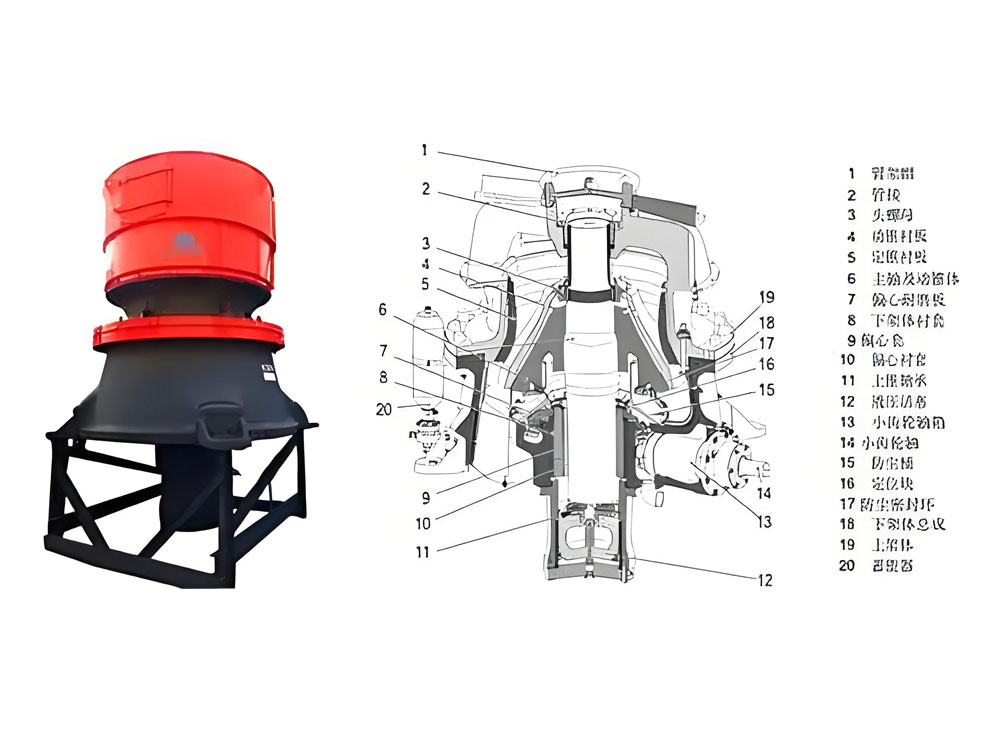

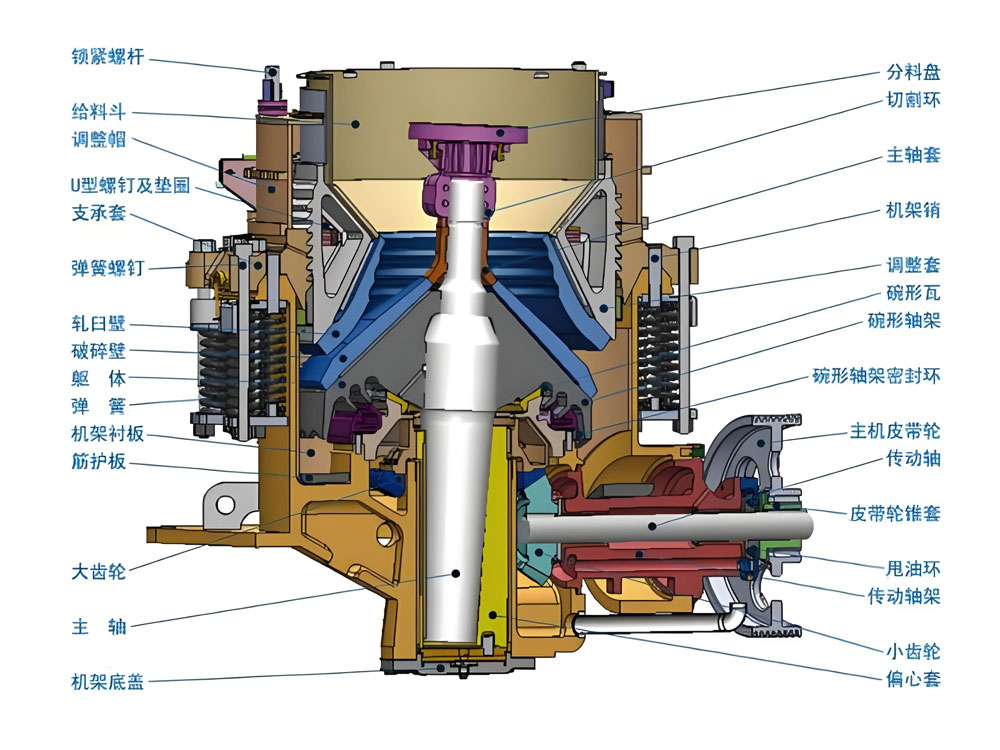

The working principle of CH870i cone crusher is based on the precise synergy of the moving cone and the fixed cone. Through a series of complex physical processes - extrusion, impact and grinding, the material is efficiently crushed. This working principle not only ensures the efficiency of the crushing process, but also ensures the uniformity and quality of the particle size of the crushed product.

When the material enters the crushing chamber evenly through the feed port, the crushing process officially begins. The moving cone, a key component, rotates and swings around the fixed cone under the precise drive of the eccentric sleeve. This rotating and swinging action forms a continuous crushing area, providing a continuous source of crushing power for the material.

As the moving cone rotates and swings, it gradually approaches the fixed cone. In this process, the material is tightly squeezed between the moving cone and the fixed cone. This strong squeezing effect, combined with the grinding effect of the moving cone and the fixed cone surface, causes the material to be gradually crushed into smaller particles. This crushing process is not only efficient, but also ensures that the material is fully crushed in the crushing chamber.

When the moving cone leaves the fixed cone, the smaller particles that have been formed in the crushing chamber are discharged smoothly from the discharge port under the action of gravity. The material that has not been completely crushed will continue to remain in the crushing chamber, waiting for the next round of crushing. This design ensures that the material is fully processed and crushed in the crushing chamber until it reaches the required particle size.

CH870i Cone Crusher Technical Parameters

| Max. feed size | 350 mm | Capacity | 250-500 t/h |

| Power | 600 kW | Eccentric throw range | 32 - 80 mm |

| Weight | 72,028 kg | Closed side setting range | 10 - 70 mm |