The LT200HPXmobile cone crusher is suitable for hard rock second and third breakers.

This cone crusher offers better performance, uptime and maintainability, as well as a wider range of applications.LT200HPX kinematics have been improved, and maintenance is simpler and faster because the liner doesn't need backing material.LT200HPX mobile cone crusher is a top mobile crushing and screening plant integrating R&D and design, manufacturing, sales and after-sales service. As a top mobile crushing and screening plant, LT200HPX is not only characterized by high efficiency and low energy consumption, but also high mobility and easy maintenance, which is widely used in mining, smelting, highway, etc. The processing capacity of the HP200 cone crusher is one of its core parameters, which directly reflects the productivity of the plant. The design processing capacity of the equipment is usually within a certain range, and the specific value depends on the hardness and humidity of the material as well as the set size of the discharge opening. The power of the motor determines the power output of the equipment in the process of operation, and sufficient motor power can ensure that the equipment maintains stable crushing efficiency when dealing with high hardness materials. The adjustment range of the discharge opening is crucial to the flexibility and adaptability of the LT200HPX. By adjusting the size of the discharge opening, the particle size of the crushed material can be controlled to meet the needs of different application scenarios.

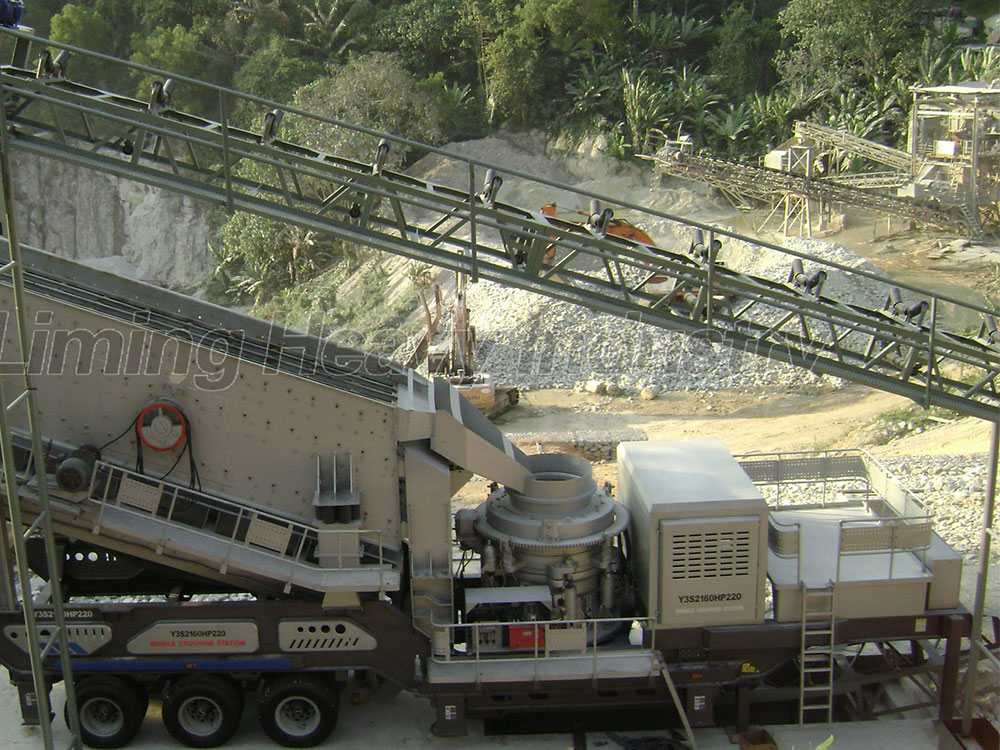

LT200HPX mobile cone crusher Applications

In the construction industry, LT200HPX mobile cone crusher is widely used in the production of building materials. It can crush raw materials such as cement, concrete, construction sand and gravel into medium fineness particles to meet the demand of producing high quality construction materials. Since the cone crusher can control the particle size by adjusting the size of the inlet and outlet, it can ensure that the construction materials produced have consistent particle size and excellent performance.

In the field of road and bridge construction, the LT200HPX mobile cone crusher also plays an important role. It is capable of crushing stone materials to provide a high-quality base material for road construction. This crusher can crush the hardest types of hard rock, such as granite, river gravel, etc., thus ensuring the construction quality of road and bridge projects. Its efficient power transmission system and excellent crushing effect make stone processing in road and bridge construction more efficient and energy-saving.

In the water conservancy industry, LT200HPX mobile cone crusher also plays an indispensable role. It can crush large stone materials and provide the required coarse and fine stone materials for the construction of water conservancy projects, such as building rubble and river embankment stones. The high crushing ratio and high output of this crusher make the stone processing in water conservancy projects more rapid and efficient, thus improving the progress and quality of the whole project.

LT200HPX mobile cone crusher Advantages

High Performance Crushing Mainframe

The LT200HPX mobile cone crusher is equipped with the HP200 cone crusher mainframe, which is capable of crushing the hardest rock types, such as granite, river gravel, etc. The HP200 series cone crusher combines optimal rotational speed, large eccentricity, crushing chamber design and powerful crushing force to achieve highly efficient crushing results. Its crushing action not only achieves the best utilization of efficiency, but also produces finer products and reduces investment and energy consumption.

High efficiency and low energy consumption

HP200 mainframe has high crushing rate and good grain shape under hard rock working condition. Excellent product shape, high crushing ratio and high throughput are achieved by increasing the eccentricity, power and crushing force, as well as improving the design and weight of the crusher to enable it to withstand greater crushing force and improve the inter-particle crushing force. In addition, the highly efficient power transmission system makes the LT200HPX extremely efficient and cost effective.

High uptime

The LT200HPX Mobile Cone Crusher utilizes a bi-directional over-iron release hydraulic cylinder that is capable of removing iron and performing large eccentric clearance operations when required. Dual accumulators improve the response speed of the hydraulic system and the IC intelligent control system optimizes the performance of the whole machine. All LT200HPX mobile crushing plants in the same crushing and screening process can be operated online with the IC system, which greatly facilitates the operator.

High mobility

The tracked design of the LT200HPX Mobile Cone Crusher allows for easy mobility and the ability to be moved around the crushing site at will. The simple design of the equipment makes it easy to transport and can be moved freely between crushing sites with high adaptability.

LT200HPX mobile cone crusher Principle

The cone crusher rotates through the motor-driven drive shaft, which in turn drives the two internal conical parts and the external fixed cone surface to rotate together, building an efficient crushing space. When the material is placed in this space, the continuous rotation of the inner and outer conical surfaces and their close fit with the cone wall make the material subject to continuous extrusion and collision, and finally complete the crushing process. Cone crusher has become an indispensable equipment for many industries such as mining, smelting, highway and so on, because of its excellent crushing performance, such as high crushing ratio, high efficiency, low energy consumption, and its ability to provide finished products with uniform particle size distribution.

LT200HPX mobile cone crusher Parameters

| Feed opening | 200 mm (8") | Pre-Screent | TK12-26-2V |

| Engine | CAT® C9.3B 310 kW (416 hp) | Weight | 42 500 kg (93 700 lbs) |

| Width | 3000 mm (9' 10) | Height | 3500 mm (11' 6") |

| ength | 19 000 mm (62') |