CJ613 Jaw Crusher Selection, Operation and Maintenance

As a leader in the field of crushing equipment, CJ613 jaw crusher has won the favour of many users with its unique design concept and excellent performance. This crusher adopts a single elbow plate design, an innovative design that not only simplifies the structure, but also plays a key role in improving the overall strength and durability. This innovative design not only simplifies the structure, but also plays a key role in improving the overall strength and durability. The single elbow plate design enables the crusher to operate more stably when subjected to huge crushing force, which effectively extends the service life of the equipment. Meanwhile, the main frame of CJ613 jaw crusher adopts welded structure, which not only enhances the overall rigidity of the equipment, but also enables the crusher to maintain excellent stability and durability under adverse working conditions. The welded structure further improves the fatigue resistance of the crusher, which enables the machine to work continuously and stably in a high-intensity operating environment. The CJ613 jaw crusher also excels in the design of crushing chamber. The deep and symmetrical design of the crushing chamber not only optimises the material flow path during the crushing process, but also significantly enhances the crushing efficiency and material passing capacity. This design enables the crusher to handle materials of various hardnesses and particle sizes more efficiently, thus meeting the needs of users in different application scenarios.

CJ613 Jaw Crusher Selection, Operation and Maintenance Applications

Firstly, with its deep and symmetrical crushing chamber design and large feed opening, CJ613 Jaw Crusher plays a crucial role in the coarse crushing process in mining. The depth and symmetry of the crushing chamber ensure the uniform force of the material in the crushing process, thus improving the crushing efficiency. At the same time, the design of the large feed opening enables the equipment to easily handle large hard rock materials such as iron ore and copper ore, providing raw materials with suitable particle size for the subsequent beneficiation or smelting process. This efficient processing capacity not only enhances the productivity of mining, but also effectively reduces energy consumption and operating costs.

In terms of structure, the CJ613 Jaw Crusher adopts a single elbow plate structure design, an innovative design that greatly enhances the fatigue resistance of the equipment and enables it to meet the demands of high-intensity operations. In long-time continuous operation, the equipment can maintain stable performance, reducing the downtime caused by equipment failure and further improving the production efficiency.

In addition, the CJ613 jaw crusher also performs well in the field of sand and gravel aggregate processing for construction. With the optimised crushing chamber structure and adjustable discharge opening device, the machine is capable of crushing granite, basalt and other high hardness rocks to achieve high output and uniform particle size of aggregate production. These high-quality aggregates are widely used in infrastructure construction projects such as highways and railways, providing a solid foundation for the country's transport construction.

In the metallurgical industry, CJ613 jaw crusher also plays an indispensable role. It is suitable for the preliminary crushing of raw materials such as ores and coke, as well as the coarse crushing needs of mineral raw materials with high hardness (such as phosphate rock and sulphurous iron ore). Its high crushing ratio and low tonnage cost characteristics make this equipment highly competitive in the metallurgical industry. By reducing the energy consumption in the subsequent processing steps, the CJ613 jaw crusher brings significant economic benefits to metallurgical companies.

In addition to the above fields, the CJ613 jaw crusher also has a wide range of applications in large-scale water conservancy projects, municipal construction and other fields. Its modular design makes the equipment easy to transport and install, and can quickly adapt to the needs of different engineering sites. At the same time, by quickly adjusting the size of the discharge opening, the equipment can meet the diversified needs of different projects for aggregate specifications, providing high-quality aggregate support for water conservancy projects and municipal construction.

CJ613 Jaw Crusher Selection, Operation and Maintenance Advantages

High-efficiency crushing performance

High efficient crushing performance is one of the highlights of this equipment. Its deep symmetrical crushing chamber and large feed opening design not only show the wisdom of engineers, but also bring significant advantages in actual operation. The deep and symmetrical crushing chamber structure, together with the oversized feed opening, greatly improves the material passing capacity and effectively reduces the risk of clogging, which is crucial for processing granite, basalt and other high hardness rocks. This design ensures that the material can enter the crushing chamber smoothly and is subjected to uniform and efficient crushing force during the crushing process, thus enhancing the overall crushing efficiency.

Flexible adjustment and easy maintenance

The trajectory and angle of engagement of the jaws have been further optimised, an innovation that significantly enhances the crushing impact. Both the upper and lower parts of the crushing chamber are fully crushed, which not only increases the throughput, but also significantly improves the crushing ratio. This means that with the same energy consumption, the equipment can produce more and finer finished products, creating greater value for users. In terms of structural design, the equipment adopts a single elbow plate mechanical design and combines high-strength alloy materials. This design not only enhances the fatigue resistance of the equipment so that it can adapt to the needs of high-intensity continuous operation, but also effectively reduces the tonnage cost. This is undoubtedly a huge advantage for crushing operations that require long hours and high loads.

In addition to its efficient crushing performance, the machine is also characterised by flexible adjustment and ease of maintenance. With the double wedge device, users can quickly adjust the size of the discharge opening to meet the production requirements of different particle sizes. This design significantly reduces downtime and improves production efficiency. Meanwhile, the frame adopts modular split design, which is easy for transport and on-site installation. Key components such as jaws and bearings can be replaced independently, which not only reduces maintenance costs, but also improves the maintainability of the equipment.

Durability and Reliability

The machine also excels in durability and reliability. The oversized bearings enhance the impact resistance and service life of the machine, while the jaws are made of high manganese steel or alloy materials to enhance wear resistance and extend the replacement cycle. In addition, through the optimisation of structural rigidity and motion parameters, the machine can maintain stable operation under extreme working conditions, effectively reducing the wear and tear of components caused by vibration.

Comprehensive cost advantages

From an economic point of view, the high crushing efficiency and low energy consumption design of this equipment reduces the cost per unit of production. At the same time, the long service life of wearing parts and simple maintenance further reduce downtime and labour costs, bringing significant economic benefits to users.

Wide applicability

Finally, the equipment also has wide applicability. It can handle all kinds of ores, rocks and construction wastes with compressive strength ≤250MPa, which is suitable for the coarse crushing needs of mining, sand and gravel aggregates, metallurgy and other fields. Whether in the tough mining environment, or in the busy construction site, the equipment can give play to its excellent performance, creating greater value for users.

CJ613 Jaw Crusher Selection, Operation and Maintenance Working Principle

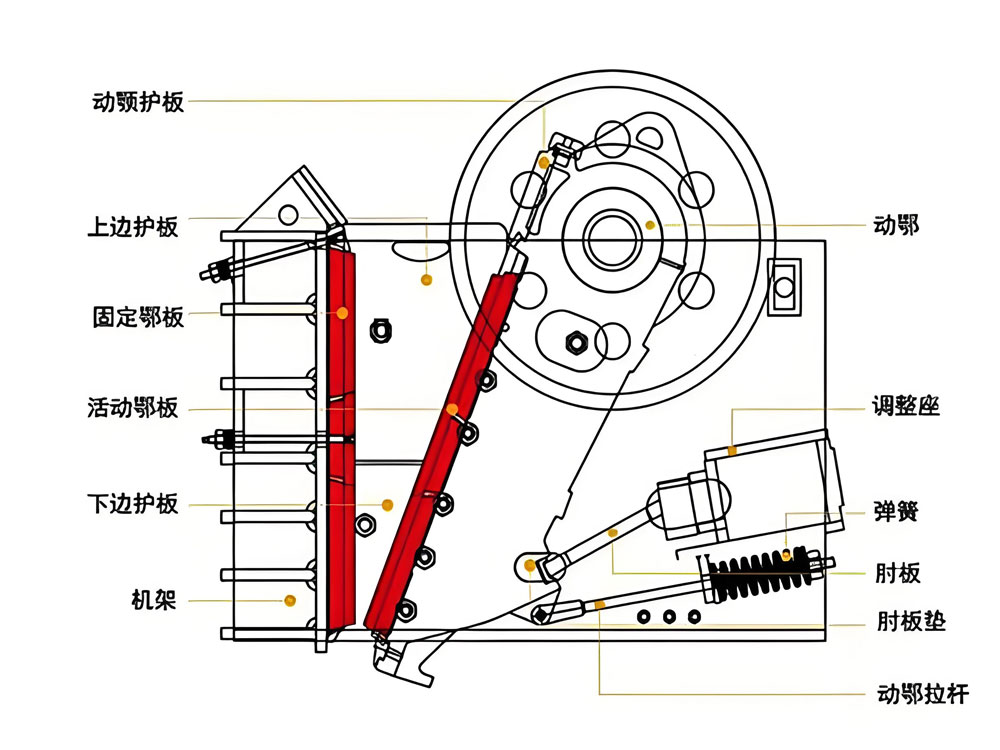

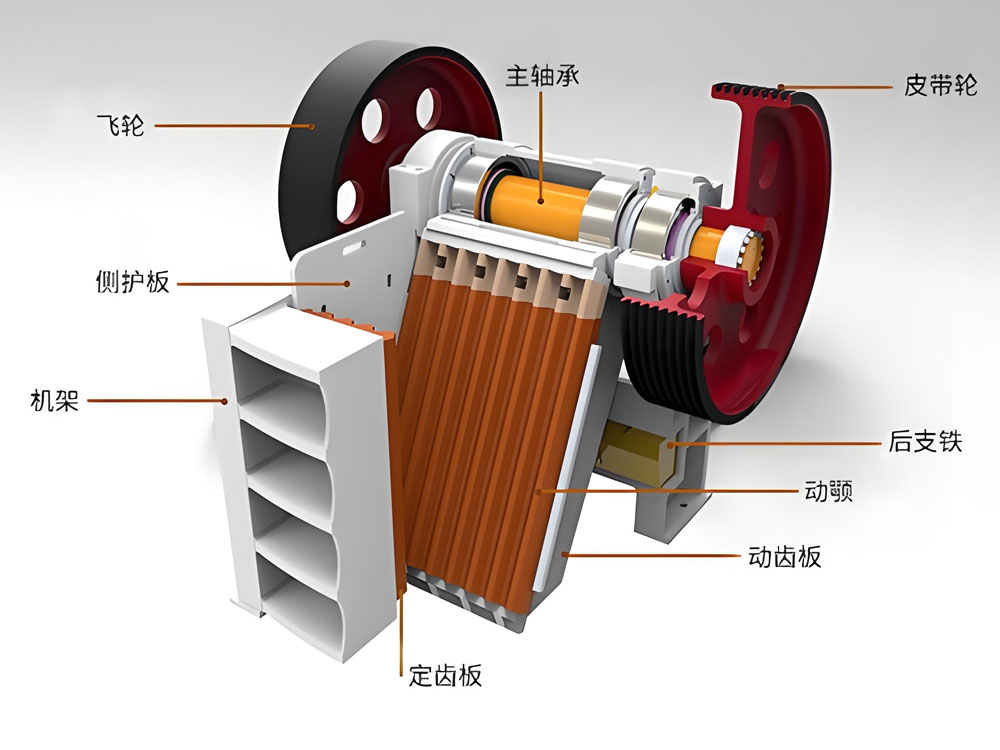

CJ613 Jaw Crusher adopts the core structure of compound pendulum jaw crusher, and material crushing is realised through the cyclic compound movement of movable jaw and fixed jaw.

The motor drives the eccentric shaft through the pulley, and the eccentric shaft drives the movable jaw (movable jaw plate) hanging on its upper end to swing in an elliptical trajectory, and the lower end of the movable jaw is hinged to the rear wall of the frame through the thrust plate. The upper part of the movable jaw has a large stroke (7-8cm), which crushes the materials by strong extrusion; the lower part has a smaller stroke (1-2cm), which is combined with high-frequency grinding to refine the particles, forming a compound crushing effect of extrusion, splitting and bending.

Large materials enter the deep symmetrical crushing chamber composed of the movable jaw and the fixed jaw from the wide mouth feeding system at the top. When the movable jaw is closed to the fixed jaw, the material is crushed by strong extrusion at the top of the cavity; when the movable jaw is swinging back, the incompletely crushed material will fall down to the lower part of the cavity automatically due to the force of gravity. In the lower part of the crushing chamber, the elliptical movement of the movable jaw makes the material receive higher frequency of extrusion and grinding. The final crushed product is discharged through the adjustable discharge opening at the bottom, which can be adjusted accurately (75-200mm) by using the double wedge device or hydraulic system to achieve precise particle size control.

Each movement cycle consists of two phases: extrusion and gravity discharge: the eccentric shaft drives the movable jaw to complete an extrusion action and then retracts, the crushed material is discharged from the chamber under the force of gravity, while new material is added to the crushing area simultaneously. The combination of deep cavity design and optimised meshing angle of 18°-20° significantly prolongs the stressing time of the material in the cavity, which improves the single crushing efficiency and reduces the return rate.

The single elbow plate mechanical structure and oversized bearings enhance the rigidity of the equipment, and the flywheel system effectively balances the inertia force of the eccentric shaft to ensure the stability of continuous crushing of high hardness materials. The flywheel energy storage design can also buffer the impact load to avoid damage to the core components caused by instantaneous overload.

CJ613 Jaw Crusher Selection, Operation and Maintenance Technical Parameters

| Feed opening | 1,300 x 1,130 mm | Weight | 45,800 kg |

| Power | 160 kW | Capacity | 600 tph |

| Feed size | 1,070.000 mm | Closed side setting range | 125.0 - 300.0 mm |