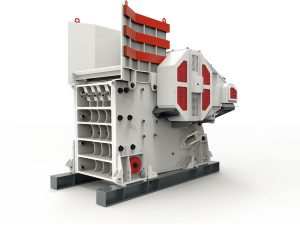

CV217 sand making machine meets diversified sand and gravel demand

CV217 sand making machine adopts advanced crushing technology and design concepts with high efficiency, energy saving and environmental protection. It is capable of crushing rocks, ores and other raw materials of various hardnesses into sand particles that meet the requirements, and is widely used in the production of sand and gravel in the fields of construction, highway, railway, etc. The working principle of CV217 Sand Making Machine is mainly based on the principle of impact crushing. After entering the crushing chamber, the material is impacted and sheared by the high-speed rotating crushing hammer head, and is crushed into smaller particles. At the same time, the impact plate in the crushing chamber also further crushes and shapes the material, making the particle size of the sand more uniform and the shape more regular.CV217 sand making machine has a strong crushing capacity, which can quickly crush the material to the required particle size and improve the production efficiency. The equipment adopts advanced energy-saving technology, which reduces energy consumption and noise pollution and meets the requirements of environmental protection. The structure of the equipment is reasonably designed, easy to disassemble and clean, reducing the maintenance cost. Crushing hammer head, impact plate and other key parts are made of high wear-resistant materials, which prolongs the service life of the equipment.CV217 sand making machine is widely used in the production of sand and gravel in the fields of construction, highway, railway and so on. It is capable of producing sand grains of various specifications and particle sizes to meet the needs of different customers. At the same time, the equipment is also suitable for crushing and sand making operations of rocks, ores and other raw materials of various hardness.

CV217 sand making machine meets diversified sand and gravel demand Applications

In the construction industry, sand and gravel, as an important raw material for concrete, asphalt and other building materials, its quality and supply stability directly affect the progress and quality of the project.With its high efficient crushing capacity and excellent granularity control ability, CV217 sand making machine is able to produce high-quality artificial sand, which can satisfy the construction industry's high standard requirements for sand and gravel. In addition, CV217 sand making machine can also adjust the discharge size according to the customer's demand, providing customised sand and gravel products for different construction projects, which improves the utilisation rate of construction materials and the quality of the project.

In the field of mining, CV217 sand making machine is widely used in fine crushing and shaping of ores. Whether it is hard rock such as granite and limestone, or soft rock such as coal and gypsum, CV217 sand making machine can crush them effectively, which provides a stable source of sand and gravel raw materials for mining enterprises. At the same time, its efficient crushing capacity also reduces the mining cost of mines and improves the economic benefits of mines.

The metallurgical industry has a high demand for sand and gravel raw materials, and has strict requirements for the quality and particle size of sand and gravel. with its excellent crushing performance and particle shape control ability, CV217 sand making machine can produce sand and gravel raw materials that meet the standards of the metallurgical industry, which provides metallurgical enterprises with a reliable production guarantee. In addition, the efficient operation of CV217 sand making machine also reduces the production cost of metallurgical enterprises and improves their market competitiveness.

In the field of infrastructure construction, such as highways, railways, bridges, tunnels and other projects, sand and gravel, as one of the important building materials, its quality and supply stability is crucial to the progress and quality of the project.With its high efficient crushing capacity and excellent particle shape control ability, CV217 sand making machine is able to produce high-quality artificial sand and aggregates, which can satisfy the high standards of sand and gravel raw materials required in infrastructure construction. . Meanwhile, its stable performance and reliable quality also ensure the smooth progress of infrastructure construction.

CV217 sand making machine is able to crush waste concrete, brick and tile and other construction wastes into recycled aggregates, which can be used to produce new construction materials. This not only reduces the pollution of construction waste to the environment, but also saves natural sand and gravel resources and realises the recycling of resources.The high efficient crushing capacity and excellent particle shape control of CV217 sand making machine make the quality of recycled aggregate guaranteed, which provides a strong support for the recycling industry.

CV217 sand making machine meets diversified sand and gravel demand Advantages

Excellent crushing efficiency

CV217 sand making machine adopts advanced crushing technology and optimised cavity design, which makes the crushing efficiency significantly improved. Its efficient crushing capacity not only shortens the production cycle and increases the output, but also reduces energy consumption and production cost. Whether it is hard rock or soft rock, CV217 sand making machine can easily cope with it and achieve fast and even crushing effect.

Excellent product shape

The CV217 sand making machine is able to produce artificial sand and aggregate with uniform particle size and regular shape through precise particle shape control during the crushing process. This excellent product grain shape not only improves the strength and durability of construction materials, but also reduces the porosity of concrete and other construction materials, thus improving construction quality. In addition, the CV217 sand making machine can also adjust the discharge particle size according to the customer's demand, so as to meet the individual demand for sand and gravel raw materials in different projects.

Energy Saving and Environmental Protection

CV217 sand making machine takes the requirements of energy saving and environmental protection into full consideration during the design and production process. Its optimised cavity design and advanced crushing technology make the dust and noise pollution in the crushing process effectively controlled. At the same time, CV217 sand making machine adopts advanced energy-saving technology, which reduces energy consumption and carbon emission and realises green production. This energy-saving and environmentally friendly design concept not only meets the current global trend of environmental protection, but also brings a good social image and market competitiveness for the enterprise.

High operational stability

CV217 sand making machine adopts high-quality materials and advanced manufacturing process to ensure the stability and durability of the equipment. Its optimised structure and reasonable layout make the equipment have low vibration and low noise during operation, which prolongs the service life of the equipment. In addition, CV217 sand making machine is also equipped with advanced monitoring and protection system, which can monitor the running status of the equipment in real time, find and deal with the faults in time, and ensure the continuity and stability of production.

Remarkable economic benefits

CV217 sand making machine brings significant economic benefits to enterprises with its advantages of high efficient crushing capacity, excellent product shape, energy saving and environmental protection design concept, high operational stability, easy operation and maintenance. On the one hand, CV217 sand making machine improves the production efficiency and product quality, reduces the production cost and energy consumption; on the other hand, its excellent performance and stable operation also win more market orders and customers' trust for the enterprise, which further improves the market competitiveness and profitability of the enterprise.

CV217 sand making machine meets diversified sand and gravel demand Working Principle

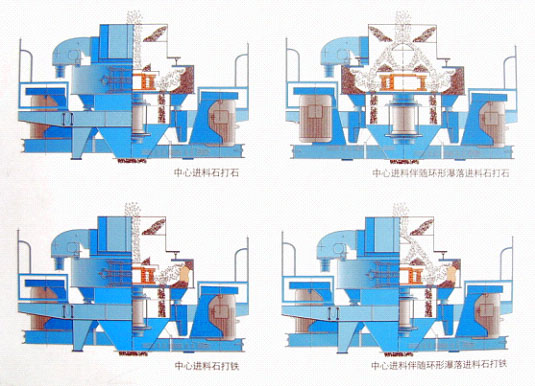

The working principle of CV217 sand making machine is mainly based on impact crushing and mutual impact between materials. The material firstly enters into the sand making machine from the feeding hopper, and after the distribution of the distributor, part of the material directly enters into the high-speed rotating impeller. Inside the impeller, the material is rapidly accelerated, and its acceleration can reach hundreds of times the acceleration of gravity, and then ejected from the three evenly distributed flow channels of the impeller at a speed of 60-70 metres per second. These high-speed projectile material first with the distributor around the free fall of another part of the material impact crushing, and then together with the impact to the vortex branch cavity of the material liner. Material in the vortex branch cavity by the material lining layer rebound, oblique upward impact to the top of the vortex cavity, and change its direction of movement, deflection downward movement. The material launched from the impeller channel and the material in the vortex cavity form a continuous material curtain, so that each piece of material in the vortex crushing cavity will be subjected to two or even more times of impact, friction and grinding and crushing effect. The material which is crushed to the suitable size is finally discharged from the lower discharge port of the sand making machine. In the whole crushing process, the materials are crushed by their own impact on each other, not in direct contact with the metal components, but crushed by impact and friction with the material lining layer, which reduces the chance of the materials being contaminated and deteriorated, and at the same time prolongs the service life of the equipment.

CV217 sand making machine meets diversified sand and gravel demand Technical Parameters

| Feed size | 50 mm | power | 185 kW |

| Length | 4.35 m | Height | 2.55 m |

| Weight | 9,500 kg | Width | 2.16 m |