Enhanced Crushing Efficiency of the PE1200×1500 Jaw Crusher

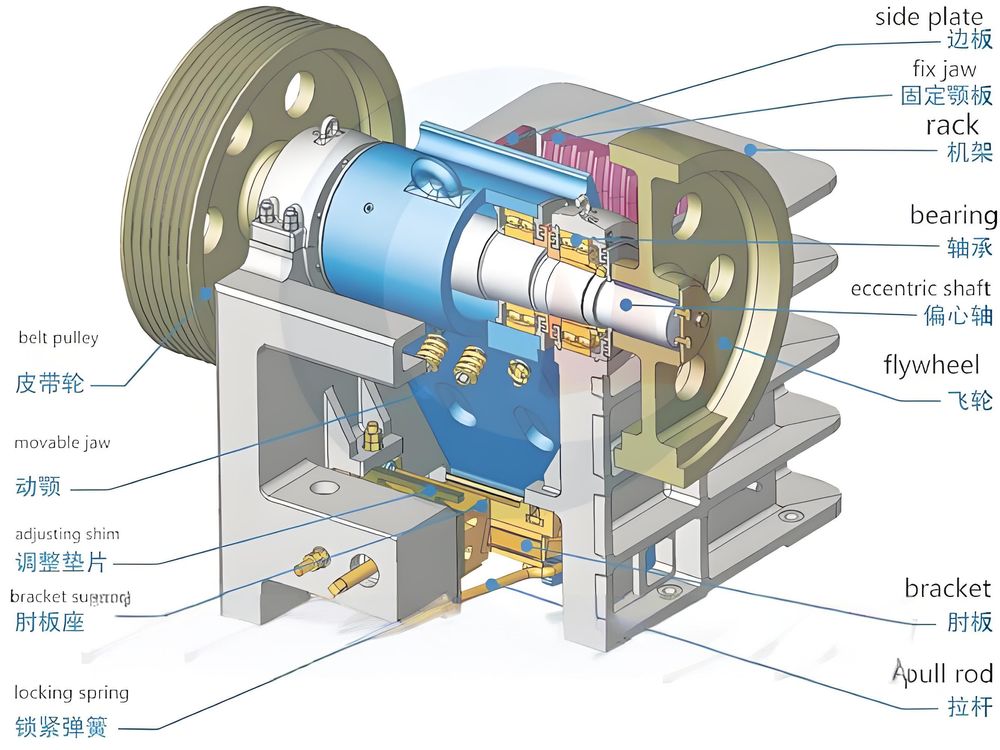

The PE1200×1500 jaw crusher is a large-scale compound pendulum jaw crusher specifically designed for processing high-hardness ores, with an upper limit of 320MPa for the compressive strength of applicable ores. This equipment is primarily used in the coarse and medium crushing stages of mining operations, metallurgical industries, and building materials production, making it particularly suitable as the core crushing equipment in large-scale sand and gravel production lines. Industry data indicates that this model holds a 37% market share in sand and gravel aggregate production lines exceeding 5 million tons annually, recognized as an efficient solution within the sector. The main structure comprises four core components: fixed jaw plate, movable jaw plate, high-strength frame, and eccentric shaft system. Specifically: the fixed jaw plate is cast from manganese steel alloy with a surface hardness of HRC 58-62, The movable jaw plate connects to the eccentric shaft via a bearing housing to achieve periodic oscillation. The frame adopts a box-type welded structure optimized through finite element analysis, enhancing fatigue resistance by 40%. The eccentric shaft is forged from 42CrMo4 alloy steel, achieving a hardness of HRC28-32 after quenching and tempering treatment.

Enhanced Crushing Efficiency of the PE1200×1500 Jaw Crusher Applications

Mining Operations

Metal Ore Crushing: Used for primary crushing of metal ores such as iron ore and copper ore, reducing large raw ore chunks to a medium particle size of 150-350mm to provide qualified feedstock for subsequent mineral processing.

Non-Metal Mineral Processing: Suitable for crushing high-hardness rocks like granite and basalt. Often integrated with cone crushers and sand makers to form complete aggregate production lines.

Building Materials & Construction Industry

Aggregate Production: Serves as primary crushing equipment in large aggregate plants, processing materials like limestone and river pebbles to produce construction aggregates.

Construction Waste Recycling: Crushes concrete blocks, bricks, and other waste materials to enable resource regeneration.

Metallurgy and Chemical Industry

Raw Material Pre-processing: Crushes iron ore, bauxite, and other metallurgical raw materials to enhance subsequent smelting efficiency.

Chemical Raw Material Processing: Crushes phosphate ore, sulfur ore, and other chemical raw materials to meet particle size requirements.

Infrastructure Engineering

Highway/Railway Construction: Crush subgrade materials to provide crushed stone meeting engineering standards.

Water Conservancy Projects: Process erosion-resistant aggregates for dams and levees.

Environmental Protection & Energy Sector

Power Plant Desulfurization: Crush limestone to prepare desulfurization agents.

Solid Waste Treatment: Co-process industrial waste residues to reduce environmental pollution.

Specialized Applications

Mobile Production Lines: Rapid deployment at temporary stockyards or dispersed mining sites when paired with mobile stations.

High-Altitude Operations: Heavy-duty structural design ensures stability in harsh environments.

Enhanced Crushing Efficiency of the PE1200×1500 Jaw Crusher Advantages

Sturdy Structure, High Load Capacity

Heavy-duty cast steel body: Utilizing integral cast steel technology and high-manganese steel jaw plates, compressive strength and wear resistance are enhanced by over 30%, ensuring long-term stable operation under harsh conditions.

Reinforced core components: Critical parts like the eccentric shaft and moving jaw assembly are forged from billet stock, significantly boosting load-bearing capacity to meet high-intensity crushing demands.

High Efficiency & Outstanding Capacity

Deep Cavity Design with Zero Dead Zones: Optimized crushing chamber ensures tight material engagement, boosting crushing efficiency by 20%. Achieves 15%-30% energy savings per unit, with system-wide energy efficiency improvements up to 50%.

High Processing Capacity: Accepts feed sizes ≤1200mm with adjustable discharge sizes (150-350mm), achieving throughput rates of 400-1000 t/h to meet large-scale production line demands.

Intelligent Safety, User-Friendly Operation

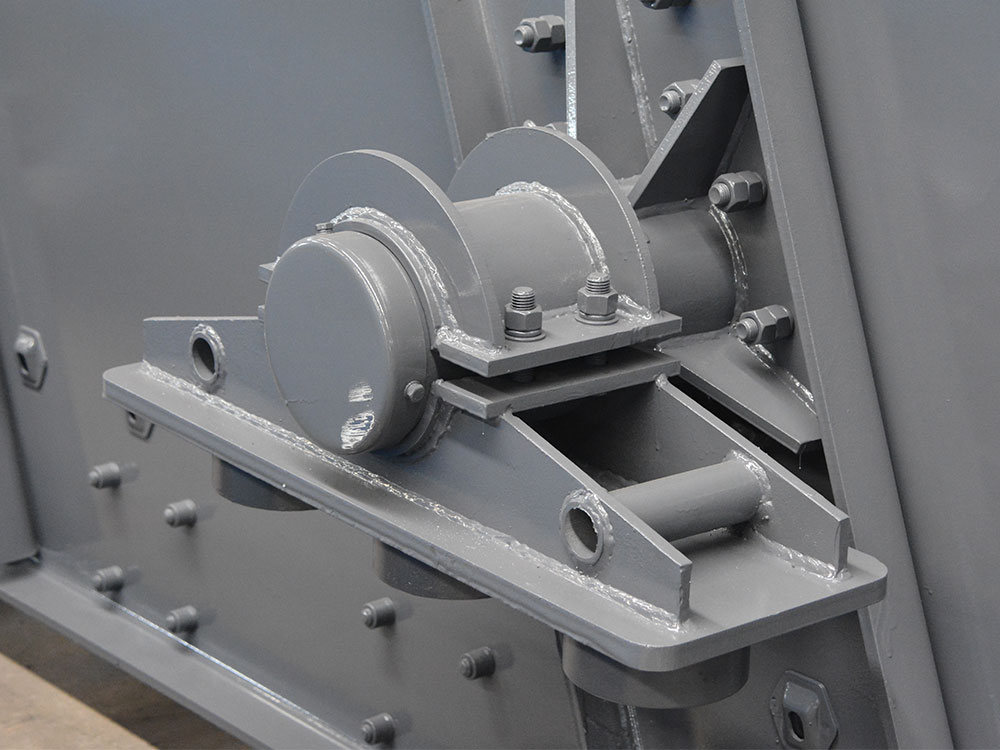

Overload Protection System: Automatic breakaway elbow plate design prevents foreign object damage. Combined with real-time monitoring, it reduces failure rates by 40%.

One-Button Start/Stop Function: Simplifies operation, reduces manual intervention, and lowers maintenance costs by 30%.

Easy Maintenance, Extended Lifespan

Centralized Lubrication System: Automated lubrication reduces manual maintenance frequency. Modular design for key component replacement cuts downtime by 50%.

Wear-Resistant Materials: High-manganese steel jaw plates and side liners extend lifespan by 30%, reducing replacement frequency of wear parts.

Environmentally Friendly & Energy Efficient

Low-Noise Design: Meets national environmental standards with noise levels below 85dB. Compatible with dust collection systems for green production.

Optimized Dust Control: Enhanced crushing chamber sealing reduces dust emissions by 60%, improving the working environment.

Versatile Compatibility, Multi-Functional Operation

Multi-Material Compatibility: Processes materials with compressive strength ≤320MPa, including granite, iron ore, and construction waste.

Flexible Discharge Adjustment: Spacer-type discharge opening mechanism enables wide particle size range to suit diverse process requirements.

Enhanced Crushing Efficiency of the PE1200×1500 Jaw Crusher Works Principle

The PE1200×1500 jaw crusher employs a double-pendulum curved-squeeze crushing principle, achieving material fragmentation through the periodic motion of the movable and fixed jaws. Its core operational process is as follows:

Power Transmission and Motion Mechanism

The motor drives the eccentric shaft rotation via a V-belt, causing the movable jaw plate to perform periodic reciprocating motion. The eccentric shaft rotates at 180 r/min. The upper end of the movable jaw is directly suspended from the eccentric shaft, while its lower end connects to the frame via a thrust plate, forming a compound pendulum motion trajectory.

Material Processing in the Crushing Chamber

Compression Crushing Stage: As the movable jaw rises, the angle between the toggle and movable jaw increases, pushing the movable jaw plate toward the fixed jaw plate. Material undergoes compression, splitting, and bending within the 1500×1200mm deep chamber.

Discharge Stage: As the movable jaw descends, the elbow plate angle decreases. The tie rod spring returns the movable jaw plate to its original position, discharging the crushed material (150-350mm particle size) through the discharge opening.

Synergistic Functioning of Key Components

Jaw Plates: Constructed from high-manganese steel with a serrated design to enhance crushing efficiency.

Elbow Plate: Serves as both a force transmission component and an overload protection device, automatically fracturing upon encountering non-crushable objects.

Clearance Adjustment Device: Spacer-type discharge opening adjustment mechanism for flexible control of output particle size.

Continuous Operation and Automation

During continuous motor operation, the moving jaw completes one crushing and discharging cycle per rotation, achieving batch production of 400-1000 t/h. A centralized lubrication system ensures stable operation of critical components like bearings.

Through optimized motion trajectories and chamber design, this equipment delivers high efficiency and energy savings (15%-30% per unit), suitable for coarse crushing of ores with compressive strength ≤320 MPa.

Enhanced Crushing Efficiency of the PE1200×1500 Jaw Crusher Technical Parameters

| Feed opening size | 1200×1500 | Feed size | ≤1020 |

| Discharge opening size | 150-300 | processing capacity | 400-800 t/h |

| Motor power | 160-220 | Weight | 100.9 t |