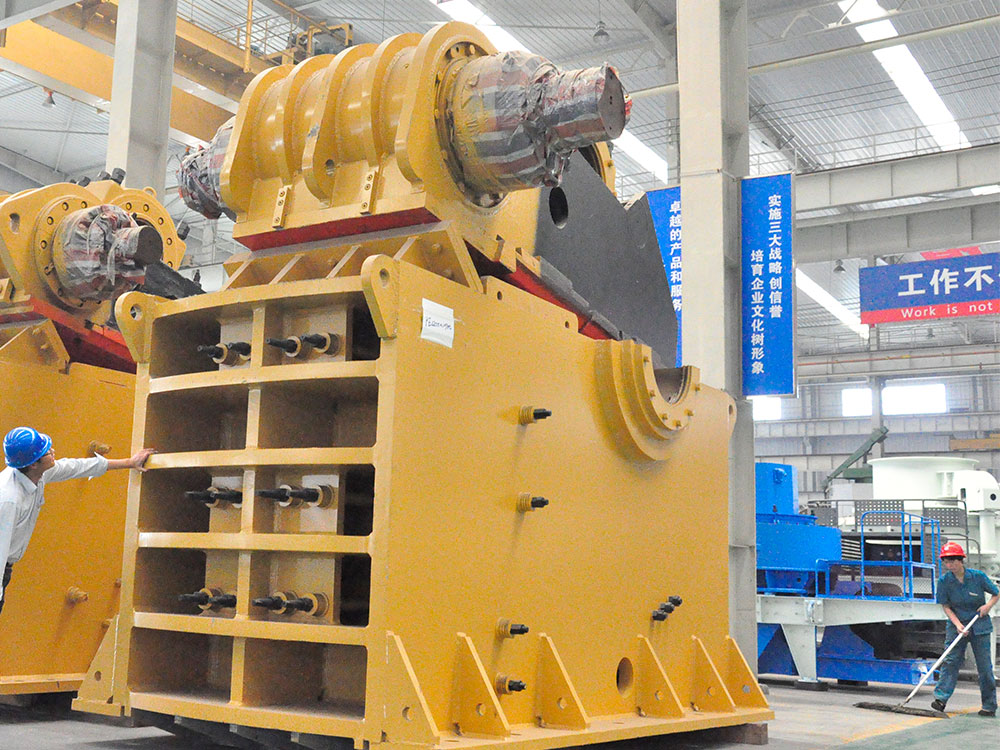

Explore the manufacturing process and technical prowess behind the C116 jaw crusher

With large handling capacity and high crushing efficiency, C116 Jaw Crusher can easily cope with the demand for coarse crushing of a large amount of materials in mining, gravel quarry, cement plant, road construction, metallurgy, chemical industry and other industries. Its compact structure and small footprint make it easy to install and move. It is widely used in many fields, whether it is crushing ores and rocks of various hardnesses or processing materials such as construction wastes, it can be used with ease, providing these industries with crushing products of superior quality. The advanced crushing chamber design and optimised trajectory of the movable jaw enable it to achieve high crushing efficiency and multiply production capacity. The jaw plate made of high wear-resistant material has a long service life, which greatly reduces the frequency of jaw replacement and maintenance costs.C116 jaw crusher also has an adjustable crushing chamber outlet size, which allows it to adjust the size of the crushed product according to the need, easily meet different production needs. The advanced manufacturing process and high-quality parts, moreover, ensure its stable and reliable operation, and the failure rate and downtime are greatly reduced. When purchasing, we really should choose the right model and specification of equipment according to our own needs, and always pay attention to the quality of equipment and after-sales service to ensure that our production can run smoothly.

C116 jaw crusher Applications

In the process of mining, C116 jaw crusher is capable of rough crushing ores of various hardnesses and providing suitable raw materials for subsequent processing. Its efficient crushing capacity and stable operation performance make it highly favoured in the mining industry. In gravel quarries, C116 jaw crusher is commonly used to crush large rocks into gravel particles that meet the requirements. Its large handling capacity and high crushing efficiency make it play a pivotal role in the gravel quarry. In the process of cement production, C116 jaw crusher is able to pre-treat raw materials and crush them into a size suitable for subsequent processing. This not only improves production efficiency, but also reduces energy consumption and costs. In road construction, C116 Jaw Crusher can crush various rocks and construction wastes to provide high quality crushed stone materials for road construction. Its crushed gravel particles are uniform and can meet the needs of different road construction. In metallurgical industry, C116 Jaw Crusher is often used to crush ores and provide suitable raw materials for subsequent smelting. Its powerful crushing capacity and wear-resistant jaw design make it widely used in the metallurgical industry. In chemical production, C116 Jaw Crusher is able to crush some chemical raw materials to meet the demand of subsequent processing. Its stable operation performance and adjustable crushing chamber outlet size make it also has certain application value in chemical industry.

C116 jaw crusher Advantages

The C116 Jaw Crusher stands out with its compact structural design and small footprint, making it easy to install and move around in a variety of limited spaces. This is a unique advantage that allows the C116 Jaw Crusher to be utilised to its full potential in site-restricted crushing operations.

The C116 jaw crusher also excels in terms of flexibility. The machine is equipped with an adjustable chamber outlet size, which makes it easy to adjust the size of the crushed product according to the actual needs. This design enables the machine to cope with a variety of materials and crushing needs, showing strong adaptability and practicality.

In terms of operational stability, the C116 Jaw Crusher adopts advanced manufacturing technology and high-quality parts to ensure the smooth and reliable operation of the equipment. This not only reduces the failure rate and downtime, but also significantly improves the productivity and economic benefits of the equipment.

The jaw plates of the C116 Jaw Crusher are made of highly wear-resistant materials with excellent wear resistance and durability. This greatly reduces the frequency of jaw plate replacement and maintenance costs, making the equipment more economical and efficient in operation.

In addition, the C116 Jaw Crusher has a highly efficient crushing capacity. Its advanced crushing chamber design and optimised trajectory of the moving jaws result in a significant increase in crushing efficiency. This design not only improves the processing capacity of the equipment, but also ensures that the size of the crushed material is uniform, which meets the stringent requirements of different industries for crushing products.

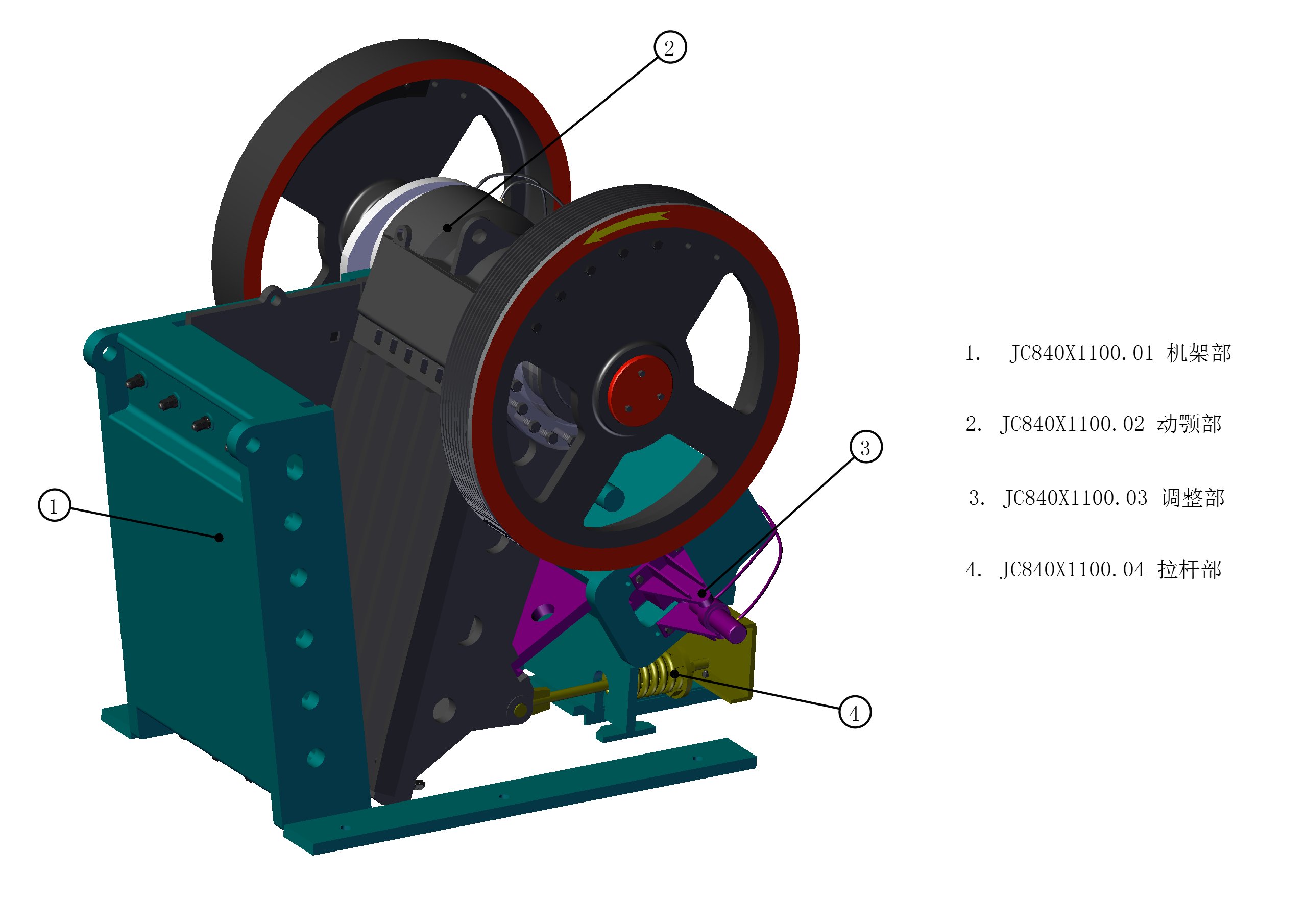

C116 jaw crusher Working Principle

The working principle of the C116 Jaw Crusher, in short, relies on the force of crushing by squeezing to achieve its purpose. The machine consists of a fixed jaw plate and a movable jaw plate, while the movable jaw plate is cleverly linked to the drive unit through an eccentric shaft. Once the drive unit is activated, the eccentric shaft starts to rotate, which in turn drives the movable jaw plate in an up-and-down reciprocating motion.

During the crushing process, the material is cleverly placed in the crushing chamber formed by two jaw plates. As the movable jaw moves slowly downwards, it gradually approaches the fixed jaw and exerts constant squeezing pressure on the material. The material is subjected to increasing pressure in the gap between the jaws until it is finally crushed to the required particle size. When the movable jaw completes a downward movement, it will move upward with the force of the eccentric shaft, at this time, the crushed material will be automatically discharged from the outlet of the crushing chamber under the action of gravity. Subsequently, the movable jaw plate starts to move downward again and enters into the next crushing cycle.

In addition, the C116 Jaw Crusher has a practical function, which is the adjustability of the crushing chamber outlet size. By simply adjusting the outlet size, we can easily control the granularity of the material output from the crusher to meet the diverse needs of different customers.

C116 jaw crusher Technical Parameters

| speed | 260 rpm | Power | 132 kW |

| Weight | 19 240 kg | width | 1 150 mm |

| depth | 760 mm | closed side | 70 mm-200mm |