GP220 cone crusher meets various crushing needs

The GP220 cone crusher inherits the advantages of previous generations of the GP series, and has significantly improved performance in terms of moving cone and frame castings. With advanced structural design concepts, this model demonstrates excellent crushing performance, high reliability and economical production costs. Through the innovative single hydraulic cylinder drive system, the moving cone can be easily raised and lowered to complete multiple functions such as adjustment of the discharge port, cleaning of the cavity, iron handling, and overload protection. Therefore, the GP220 cone crusher has been widely used in ferrous metals, non-ferrous metals, non-metal mines, sand and gravel production and other fields, and can fully meet users' needs for high efficiency, high output and high-quality gravel products.

GP220 cone crusher meets various crushing needs Applications

GP220 cone crusher plays an important role in the metallurgical industry. In the process of metallurgical production, various raw materials need to be crushed and ground for subsequent smelting and processing. GP220 cone crusher has become one of the indispensable equipment in the metallurgical industry with its efficient crushing capacity and stable operating performance.

GP220 cone crusher is widely used to crush ores of various hardness and toughness. Its powerful crushing capacity and high crushing ratio enable the ore to be quickly crushed into the required particle size to meet the subsequent smelting or processing needs. In addition, the wear resistance and reliability of GP220 cone crusher also ensure its continuous and stable operation in harsh mining environments.

The construction industry is also one of the important application areas of GP220 cone crusher. In the preparation process of building materials, various raw materials need to be crushed and screened to obtain building materials that meet the requirements. GP220 cone crusher can quickly crush raw materials into the required particle size to meet the preparation needs of building materials.

GP220 cone crusher has also been widely used in the chemical and silicate industries. These industries need to crush and grind various raw materials for subsequent chemical reactions or processing. The GP220 cone crusher's efficient crushing capacity and stable operating performance enable it to meet the strict requirements of these industries for raw material crushing.

GP220 cone crusher meets various crushing needs Advantages

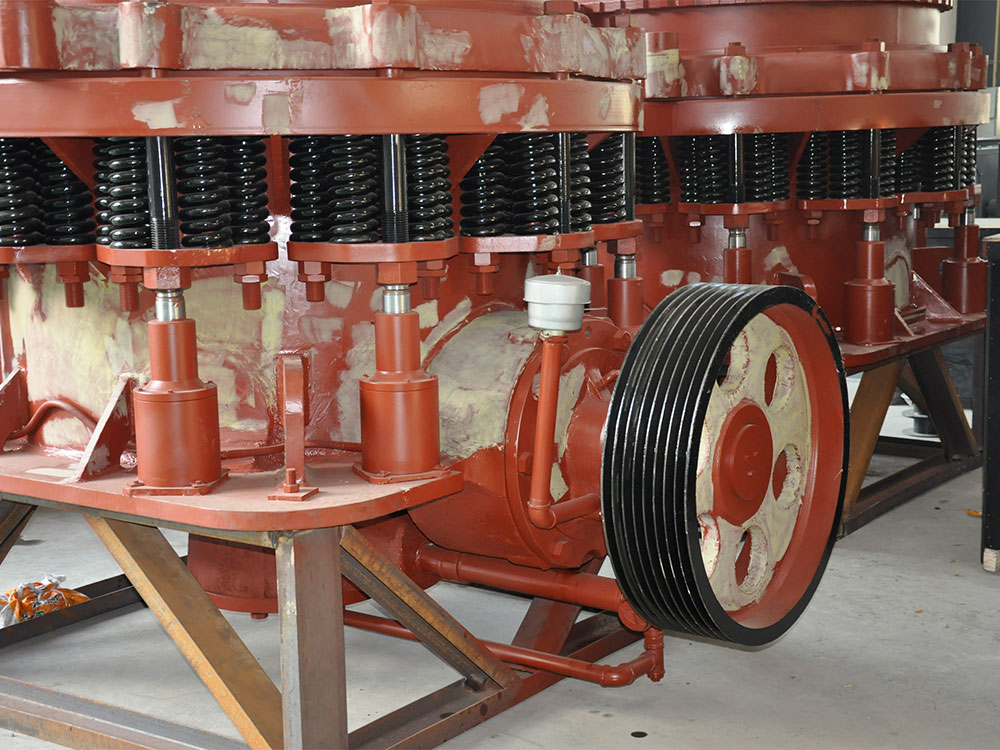

The advantage of GP220 cone crusher is first reflected in its powerful crushing capacity. This equipment adopts the cone crushing principle and uses a single hydraulic cylinder to lift and lower the movable cone to achieve multiple functions such as adjustment of the ore discharge port, cleaning the cavity, iron passing, and overload protection. This design not only improves the crushing efficiency, but also enables the equipment to maintain continuous and stable operation during the production process. At the same time, the GP220 cone crusher is designed with a perfect combination of crushing stroke, crushing speed and crushing cavity shape, which significantly improves its output compared with traditional old-fashioned cone crushers.

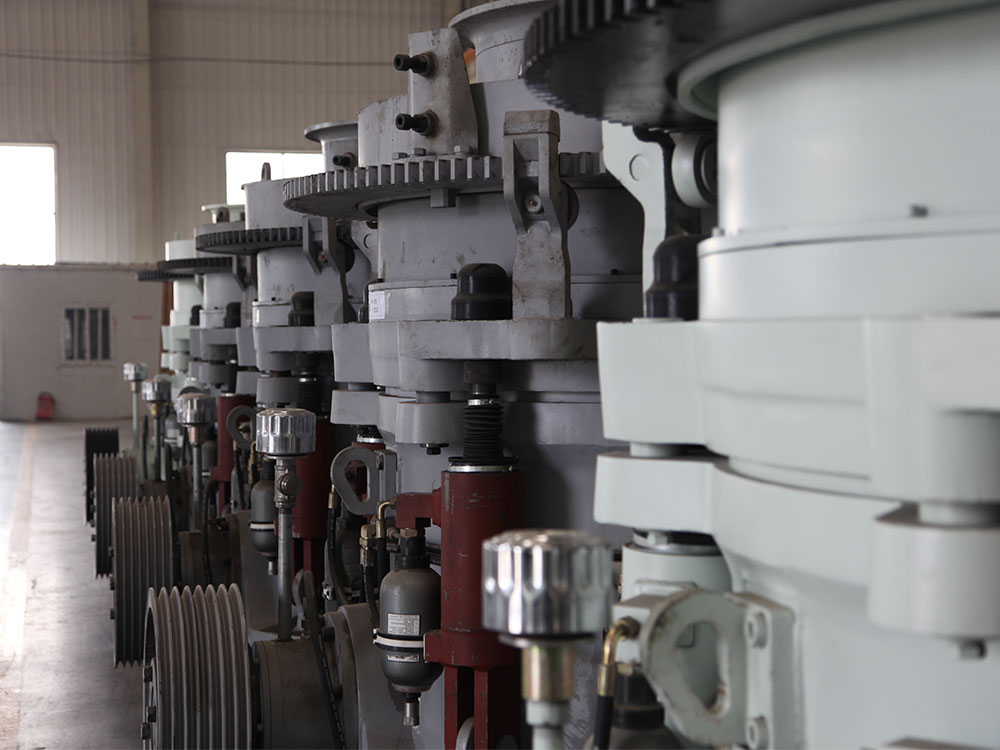

In terms of reliability and durability, the GP220 cone crusher also demonstrates its excellent quality. It has a simple but sturdy two-point supported spindle design for high mechanical reliability. At the same time, the equipment uses durable, optimized components to extend its service life and reduce maintenance costs. When maintenance is needed, it can be disassembled from the top and all heavy components can be lifted, making maintenance work more convenient and faster. Equipped with an automated system to continuously monitor the crusher load and operating parameters to ensure optimal operating conditions and highest availability. This level of automation not only improves production efficiency, but also reduces the risks of manual operations and improves the safety of factory personnel.

The GP220 cone crusher also performs well in terms of product quality. It adopts a unique crushing cavity shape and lamination crushing principle, which significantly increases the proportion of cubes in the product, reduces needle-shaped stones, and makes the particle size more uniform. This high-quality stone product not only meets the market's demand for high-quality aggregates, but also increases the added value of the product.

In terms of adjustment performance, the GP220 cone crusher also has significant advantages. The bottom hydraulic cylinder adjusts the upper and lower positions of the main shaft, thereby changing the distance between the moving cone and the outer cone lining plate, and realizing flexible adjustment of the size of the discharge port. This adjustment method is simple and easy to operate and can quickly adapt to different production needs. At the same time, the design of adjustable eccentricity enables the crusher to achieve appropriate packed feeding conditions and optimal discharge opening, ensuring the highest output of the required final product particle size.

The GP220 cone crusher is designed for easy maintenance and repair. The use of durable, optimized parts extends the life of the equipment, but whenever repairs are needed, the GP220 cone crusher can be disassembled from above and all heavy components can be lifted. The lower installation height of the GP220 cone crusher requires smaller support structures and shorter conveyors, reducing installation costs.

GP220 cone crusher meets various crushing needs Working Principle

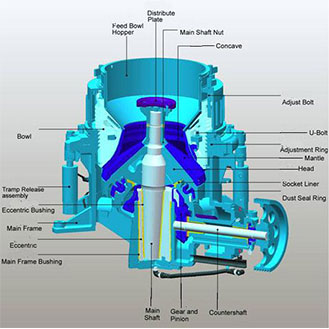

GP220 cone crusher is mainly composed of core components such as crushing shell, crushing chamber, moving cone and fixed cone. These components work together to complete the material crushing task. The crushing shell is the external protection structure of GP220 cone crusher. It can not only withstand the huge pressure generated during the crushing process, but also effectively prevent the material from leaking out, ensuring the stable operation of the crusher. The crushing chamber is located inside the crushing shell and is the main place for material crushing. Its unique structural design allows the material to be fully squeezed and ground in the chamber, thereby achieving efficient crushing effect. Moving cone and fixed cone are the core crushing components of GP220 cone crusher. The moving cone drives the transmission shaft through the motor, and then drives it to rotate through components such as pulleys. Driven by the eccentric shaft, the moving cone performs eccentric rotation on the inner surface of the fixed cone. This movement mode causes the gap between the moving cone and the fixed cone to change continuously, thereby exerting strong squeezing, bending and grinding effects on the material. When the material enters the crushing chamber, it will be immediately squeezed by the moving cone and the fixed cone. As the moving cone rotates and approaches the fixed cone, the pressure on the material gradually increases until it reaches its crushing limit and is crushed. When the moving cone leaves the fixed cone, the crushed material is discharged from the bottom of the cone and enters the gap of the crushing chamber. These gaps are carefully designed to ensure the smooth discharge of the crushed material while preventing the passage of oversized particles, thereby ensuring the uniformity of the particle size of the crushed product. During the crushing process, larger particles of material will continue to be squeezed and impacted by the moving cone and the fixed cone until they are completely crushed and discharged. This continuous and efficient crushing method enables the GP220 cone crusher to perform well in handling materials of various hardness and particle sizes.

GP220 cone crusher meets various crushing needs Technical Parameters

| Weight (without accessories) | 11 100 kg (24 470 lbs) | Power | 132 - 220 kW (175 - 300 hp) |

| Maximum feed size | 204 mm (8 1/32") | Stroke options | 18, 25, 28, 32, 36, 40 mm (11/16, 1, 1 7/64, 1 ¼, 1 13/32, 1 9/16") |

| Maximum capacity | 310 Mtph (341 Stph) |