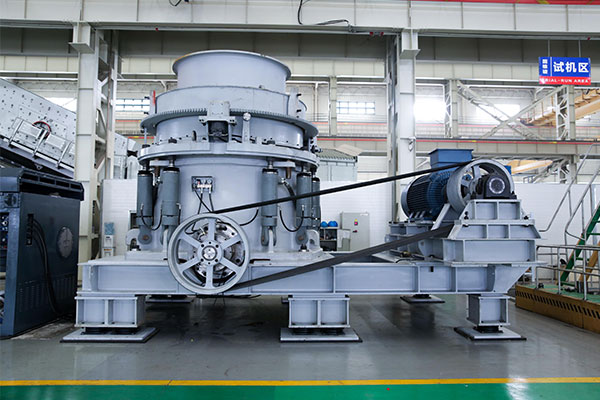

GP330 cone crusher for efficient crushing in fixed and mobile applications

The GP330 cone crusher perfectly adapts to the different needs of each crushing stage with its diverse cavity contour design. The spindle stroke is designed to be as long as possible. This feature significantly improves the utilization of manganese wear parts, thereby reducing the frequency of liner replacement and waste. This is also an important reason why the GP330 crusher can use extremely thick and heavy-duty wear parts. In addition, the GP330 cone crusher is equipped with a unique high pivot point design, which is cleverly located in the middle of the top bearing, ensuring the smoothness of the top stroke of the chamber, further extending the service life of the equipment and reducing Wear and scratches. It is worth mentioning that the high pivot point design also facilitates the smooth flow of sticky or wet materials. The overall design of the GP330 cone crusher is designed to maximize the feed flow inside the crusher, for example by enlarging the open discharge area of the lower frame. In addition, the performance of the GP cone crusher is less sensitive to changes in the feed material level in the cavity, a unique feature that undoubtedly adds further advantages.

GP330 cone crusher for efficient crushing Applications

In mining, GP330 cone crusher is often used to crush ore into the required particle size for subsequent beneficiation, smelting and other processes. Its powerful crushing capacity and adaptability to hard rock make it an indispensable crushing equipment in the mining field.

In the construction industry, GP330 cone crusher can be used to process materials such as construction waste and waste concrete, converting them into recycled aggregates for the production of new building materials. This not only helps environmental protection, but also improves resource utilization.

In infrastructure construction such as roads and railways, GP330 cone crusher can be used in processes such as stone processing and roadbed filling. Its efficient crushing performance and stable operating status provide high-quality fillers and solid support for infrastructure construction.

In the recycling industry, GP330 cone crusher can be used to crush scrap metals, plastics and other materials for subsequent reuse. Its sturdy structure and durable design enable it to maintain excellent performance when processing various waste materials.

GP330 cone crusher for efficient crushing Advantages

The GP330 cone crusher is unique among crushers of the same size class for its excellent crushing efficiency and stable performance. It can produce the same amount of material in a shorter time, thanks to its advanced crushing technology and sophisticated structural design.

This sturdy cone crusher is built to cope with the toughest hard rock crushing sites. Its further optimized casting design ensures excellent durability under higher pressure and 315kW nominal power applications, allowing users to use it for a long time without frequent maintenance or replacement.

The GP330 cone crusher provides users with flexible and diverse adjustment options, and its standard 7 eccentric throws are achieved through an eccentric sleeve. Users can easily adjust the crushing chamber and eccentric throw according to specific application requirements to achieve higher output, better product quality and lower wear parts costs.

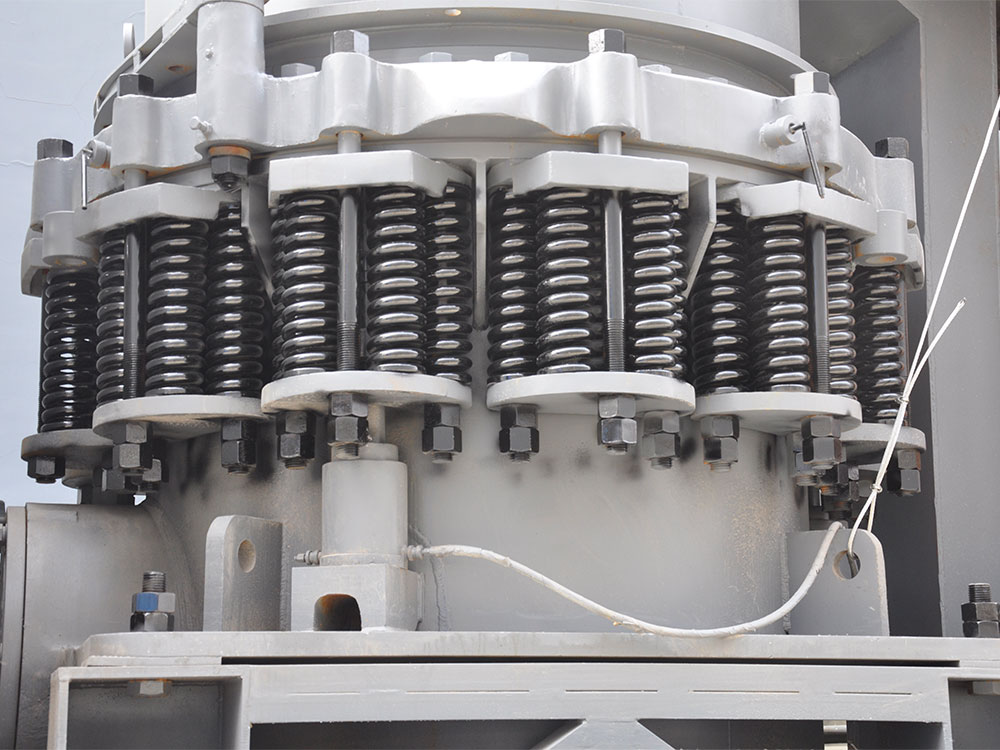

In addition, the equipment has undergone a series of innovative improvements, and the expansion of its spindle vertical motion range helps reduce wear parts costs and extend service life. At the same time, the increased iron release distance of unbreakable objects further reduces the risk of damage to the crusher internals, bringing users higher operational benefits.

GP330 cone crusher also performs well in operation and maintenance. Its maintenance points are designed to be safe and convenient, and all the necessary safety maintenance tools are included. The advanced automation system ensures the simple operation, safe operation and trouble-free performance of the equipment.

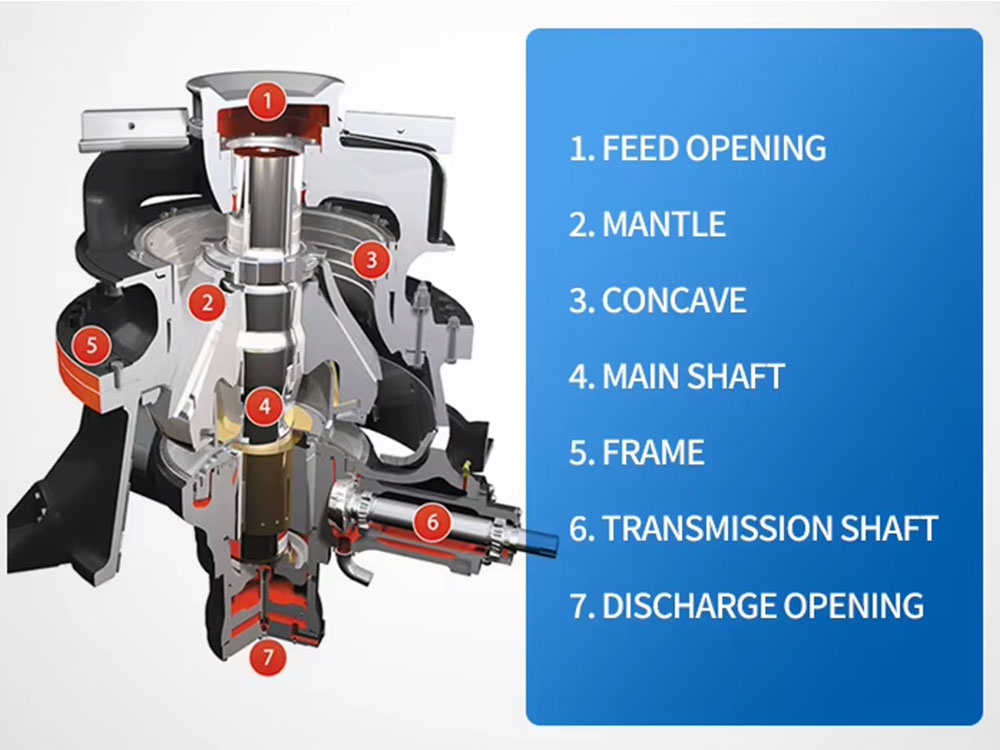

GP330 cone crusher for efficient crushing Working Principle

First, the material is evenly fed into the annular crushing chamber composed of a moving cone and a fixed cone. Subsequently, the motor drives the eccentric sleeve to rotate through the transmission device, and then drives the moving cone to do a rotary pendulum motion. In this process, the surface of the moving cone will sometimes approach the inner surface of the fixed cone, and sometimes leave it. When the moving cone is close to the fixed cone, the material between the two cones will be subjected to strong squeezing, rubbing and bending, thereby achieving crushing. Under the combined action of gravity and the rotary pendulum motion of the moving cone, the crushed material will be discharged from the discharge port at the bottom of the cone. It is worth noting that the GP330 cone crusher is standardly equipped with multiple eccentric distances, but all use one eccentric sleeve. Users can adjust the crushing effect and output of the crusher by changing the crushing chamber and eccentric distance according to actual application requirements. This design not only improves the flexibility and adaptability of the crusher, but also provides users with more choices and convenience.

GP330 cone crusher for efficient crushing Technical Parameters

| Weight (without accessories) | 16 600 kg (36 600 lbs) | Power | 250 - 315 kW (325 - 425 hp) |

| Maximum feed size | 215 mm (8 15/32") | Stroke options | 32, 36, 40 mm |

| Maximum capacity | 420 Mtph (462 Stph) |