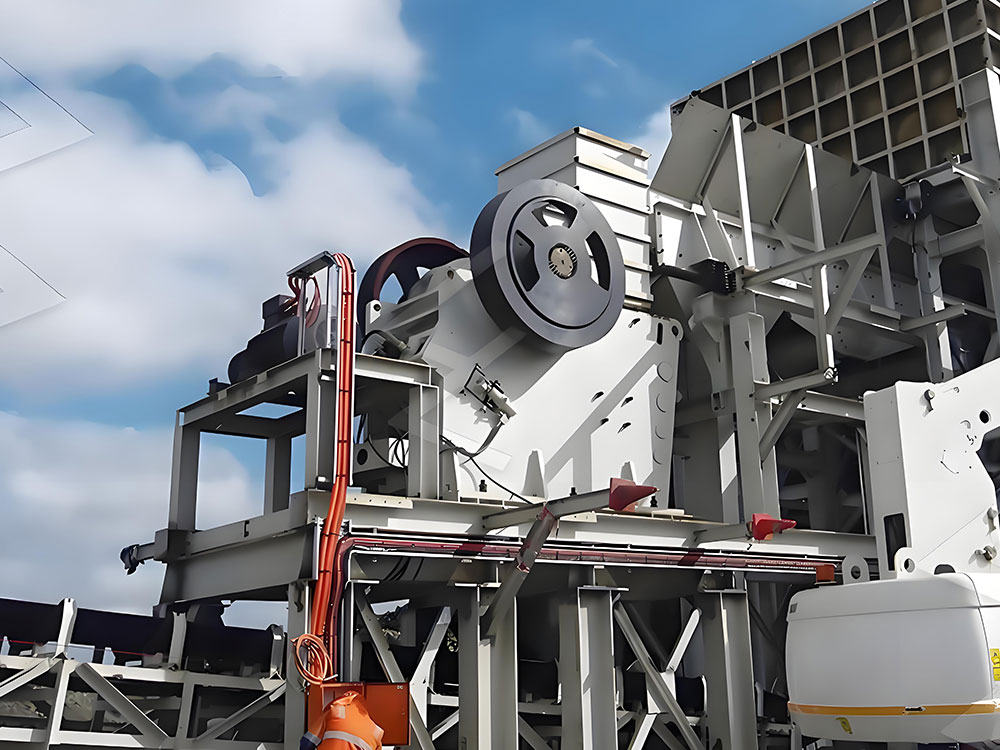

High-capacity CJ212 Stationary jaw crushers

The CJ212 jaw crusher, a star product of the company and a representative example of a stationary single-toggle jaw crusher, is highly sought after within the industry.

It boasts a unique structural design. Its deep, symmetrical crushing chamber, combined with a large feed opening measuring 1100 x 700 mm (43 x 27 inches), easily handles large materials. A hydraulic wedge-type discharge opening adjustment mechanism allows for flexible adjustment of the discharge opening to accommodate varying particle size requirements.

The CJ212 boasts exceptional performance. It utilizes advanced technology and a reliable welded design to ensure long-term, stable operation. Its efficient crushing capacity allows for outputs of 80 to 490 tons per hour, meeting the demands of large-scale production. Furthermore, its ease of maintenance and minimal downtime significantly reduce operating costs.

In terms of technical specifications, the CJ212 weighs 14,300 kg (31,500 lb) and is equipped with a 90 kW motor, providing ample power. Its adaptability allows for stable operation on a variety of complex construction sites. The CJ212 plays a vital role in practical applications. In aggregate production, it serves as a primary crusher, providing ideal raw materials for subsequent fine crushing and screening. In mining, it provides preliminary ore crushing, improving extraction efficiency. Its stable performance and reliable quality bring significant economic benefits to users, making it an indispensable piece of equipment in the mining and building materials industries.

High-capacity CJ212 Stationary jaw crushers Applications

The CJ212 jaw crusher has demonstrated significant application value in numerous industries, becoming a vital piece of equipment driving their development.

The metallurgical industry has stringent requirements for raw material particle size, and the CJ212 jaw crusher plays a key role in this process. Before metal smelting, ore must be crushed to maximize metal extraction efficiency. The CJ212 jaw crusher efficiently crushes ore into a suitable particle size, effectively exposing the metal elements within the ore and facilitating subsequent smelting processes. For example, in copper smelting, ore crushed by this equipment significantly improves leaching and electrolytic efficiency.

In cement processing, the CJ212 jaw crusher is used for coarse crushing of raw materials such as limestone. Limestone is one of the primary raw materials in cement production, and its particle size directly impacts cement quality and production efficiency. The CJ212 jaw crusher can break large limestone lumps into uniform particles, providing the appropriate feed for the cement mill and ensuring stable cement production. The CJ212 jaw crusher is also a key application for urban construction waste disposal. With the acceleration of urbanization, the amount of construction waste generated is increasing. The CJ212 jaw crusher can crush concrete blocks, bricks, and other construction waste into recycled aggregate for use in road bases, backfill materials, and other applications, thereby repurposing construction waste as a resource and reducing environmental pollution.

In water conservancy and hydropower projects, the CJ212 jaw crusher is used to crush stone, providing high-quality sand and gravel aggregate for construction. Whether it's dam construction or river dredging, large quantities of sand and gravel are required. This equipment can meet the project's requirements for sand and gravel particle size and quality, ensuring smooth project execution. Its strong adaptability and stable operation enable it to perform effectively in a variety of complex engineering environments.

High-capacity CJ212 Stationary jaw crushers Advantages

The CJ212 jaw crusher offers several significant advantages, making it stand out among other crushing equipment.

In terms of structural design, it features a deep, symmetrical crushing chamber with a feed opening measuring 1100 x 700 mm, easily accommodating large materials. This reduces pre-crushing pre-treatment and improves overall operating efficiency. Furthermore, the optimal engagement angle ensures smooth material flow within the crushing chamber, reducing the risk of blockage and ensuring continuous, stable operation.

In terms of performance, the CJ212 jaw crusher offers outstanding advantages. Utilizing proven technology and a reliable welded design, it offers exceptional operational stability and a low failure rate, minimizing production losses caused by equipment downtime for maintenance. Its impressive crushing efficiency and output of 80 to 490 tons per hour meet the needs of large-scale production. Furthermore, the machine is easy to maintain, requiring minimal downtime for maintenance, significantly reducing operating costs.

In terms of adaptability, the CJ212 jaw crusher excels. It can adapt to a variety of construction site conditions, enabling rapid adjustment and optimal performance, whether in a fixed installation or in conjunction with other equipment. It also has good processing capabilities for materials of different hardness and moisture. For example, when processing high-hardness ores and high-humidity coal, it can stably output products of appropriate particle size.

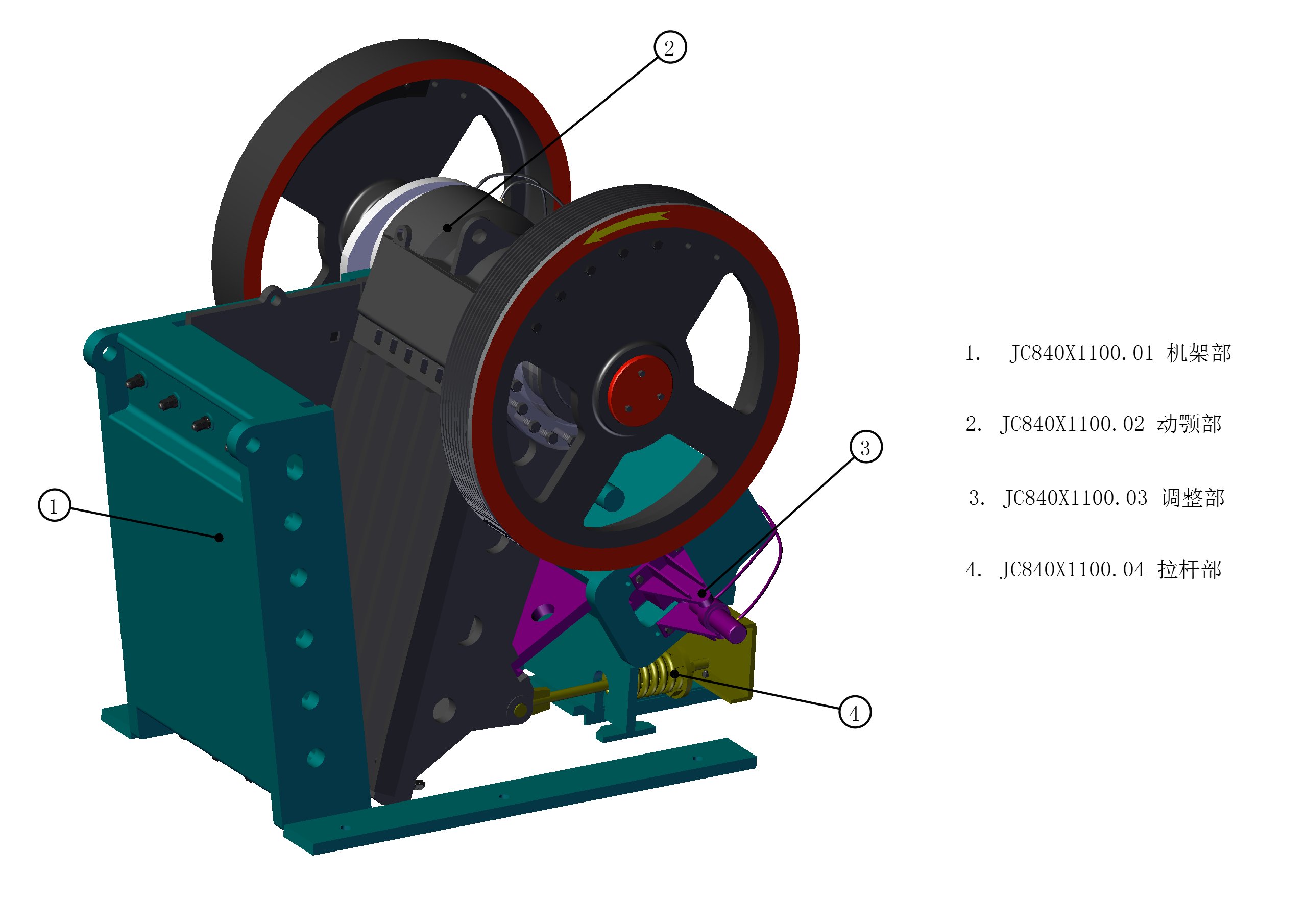

High-capacity CJ212 Stationary jaw crushers Principle

The CJ212 jaw crusher uses mechanical motion to simulate the bite of an animal's jaws to crush materials.

During operation, the motor starts, transmitting power to the eccentric shaft via a belt and pulley, causing the eccentric shaft to begin rotating. This rotation drives the movable jaw plate to oscillate periodically. As the movable jaw plate swings toward and gradually approaches the fixed jaw plate, the gap between them gradually decreases, trapping the material between the two jaw plates and subjecting it to intense squeezing, shearing, and bending forces. These combined forces crush the material.

As the eccentric shaft continues to rotate, the movable jaw plate begins to oscillate in the opposite direction, gradually moving away from the fixed jaw plate. At this point, crushed material within the crushing chamber that is smaller than the discharge port is discharged from the crushing chamber through the lower discharge port under its own weight. Material that has not been completely crushed moves downward under the influence of gravity, returning to the space between the two jaw plates to await the next crushing cycle. As the motor continues to operate, the movable jaw plate continues its cyclical oscillation, repeating the crushing and discharge processes, thus achieving continuous material crushing.

High-capacity CJ212 Stationary jaw crushers Technical Parameters

| Feed opening | 1,100 x 700 mm (43 x 27 in.) mm | Motor power | 90 kW (125 hp) |

| Weight | 14,300 kg (31,500 lb) | Length | 2.4 m (94.0 in) |

| Width | 2.4 m (94.0 in.) | Height | 2.2 m (86.0 in.) |