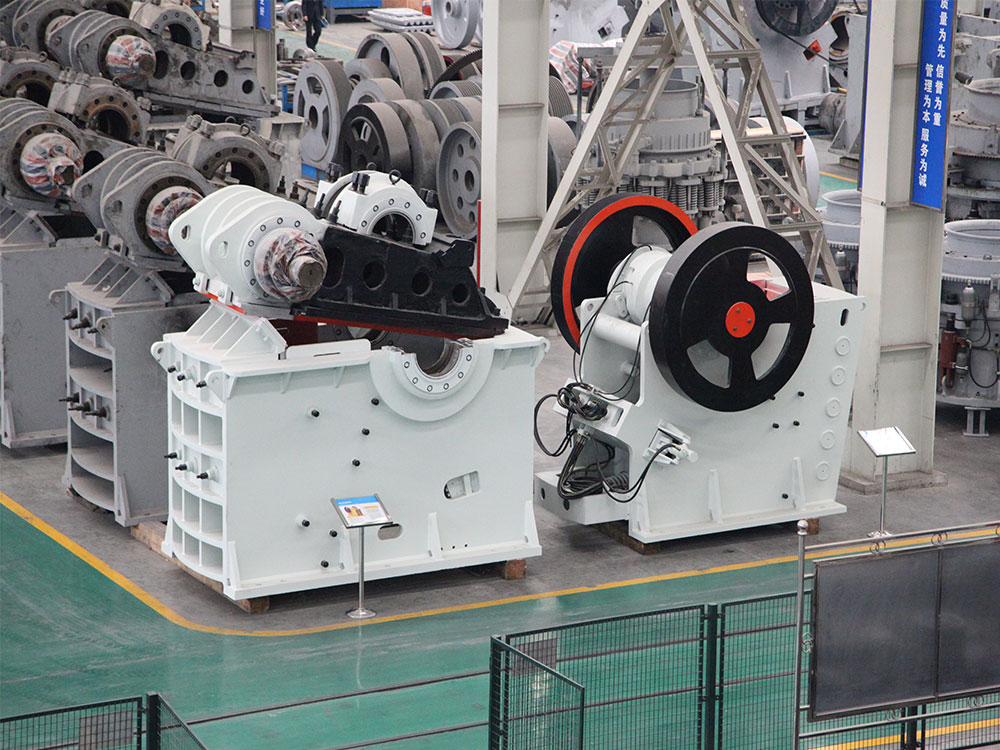

High performance and extremely reliable C150 jaw crusher

The C150 Jaw Crusher has an efficient movable jaw movement and a large eccentric distance at the bottom of the crushing chamber, making its crushing capacity outstanding. The larger feed opening increases feed capacity and ensures a smooth flow of rock into the crushing chamber, while the smaller bite angle reduces wear on the jaw liners, lowering operating costs while ensuring a fast downward flow of material through the crushing chamber. The machine delivers excellent whole-life performance, efficiently crushing large feed materials to the required product size. The enlarged feed opening handles oversize feed material up to 1 meter (40 inches) and utilizes the increased stroke at the top of the crushing chamber for efficient crushing. The small engagement angle in the middle of the chamber ensures rapid material flow to the bottom of the chamber, where crushing is accomplished by utilizing the increased stroke amplitude.The reliability of the C150 Jaw Crusher is based on pin-bolt connections and non-welded frame construction, which provides superior fatigue strength. All frame components are cast in an alloy developed specifically for jaw crushers, featuring a honeycomb structure for added ruggedness. The plant is safe and easy to operate and maintain, with a limited number of maintenance points that are easily and safely accessible. Operation, condition monitoring and greasing can be configured to be fully automated, and a dedicated component lifting tool comes as standard to make maintenance easier and safer.

High performance and extremely reliable C150 jaw crusher Applications

In large-scale mines and quarries, C150 jaw crusher is undoubtedly a powerful assistant. It can easily handle the feed material with the largest particle size, crushing it precisely into the required particle size, laying a solid foundation for the subsequent ore dressing and smelting processes. Its powerful crushing capacity and efficient crushing efficiency make it the nemesis of hard and highly abrasive rocks and minerals.

In the field of building materials production, C150 jaw crusher also performs well. Whether it is crushing limestone, granite, etc. into raw materials for concrete and mortar, or crushing all kinds of rocks and ores into aggregate that meets the requirements, it is able to do so with ease and meet the demand for high-quality raw materials in the construction industry.

C150 Jaw Crusher is also an indispensable member in road engineering. It can crush various kinds of stone materials, provide solid support for the laying of road base and pavement, and ensure the smooth progress of road projects.

In addition, C150 Jaw Crusher also plays an important role in the recycling of waste materials. It can crush waste concrete, bricks and tiles and other construction waste into recycled aggregates, realizing the recycling of resources and contributing to the development of circular economy.

Of course, the application fields of C150 jaw crusher are far beyond this. It also has a wide range of applications in chemical industry, metallurgy and other fields, and can be used to crush raw materials such as coal, sulfur, phosphorite and other raw materials, providing a stable and reliable supply of raw materials for the production of these industries. Its excellent performance and wide range of applications make the C150 jaw crusher an indispensable and important equipment in the industrial field.

High performance and extremely reliable C150 jaw crusher Advantages

Superior performance and powerful crushing capacity

The C150 Jaw Crusher is known for its long term performance and high reliability. With a large feed opening and deep steep crushing chamber, the C150 Jaw Crusher is able to easily handle oversized feed material up to 1 meter (40 inches) in size. In addition, the bottom stroke of the crushing chamber is larger, which not only increases the capacity, but also optimizes the crushing ratio to ensure high output in various operating environments.

Energy efficient and environmentally friendly

In operation, the C150 Jaw Crusher demonstrates excellent crushing efficiency and reduces energy consumption. Thanks to its unique crushing principle and structural design, materials are crushed quickly and evenly in the crushing chamber, significantly reducing energy consumption and wear. In addition, the equipment has achieved remarkable results in noise control and dust suppression, effectively reducing the impact on the environment, in full compliance with environmental requirements.

Easy to operate and maintain

The C150 Jaw Crusher is safe and easy to operate and maintain. Its modular design makes installation and dismantling quick and easy, saving time and costs. Critical areas of the machine are protected against wear, and wear components and parts are designed for easy access and replacement. In addition, the machine can be equipped with fully automated operation, condition monitoring and grease filling systems, which further enhances the ease of use and maintenance of the machine.

Wide range of applications

The C150 jaw crusher is widely used in large-scale mines, quarries and aggregate production. Its powerful crushing capacity and high crushing efficiency make it the preferred equipment for handling hard and highly abrasive rock minerals. Meanwhile, the equipment also performs well in the field of recycling, capable of crushing waste concrete, masonry and other construction waste into recycled aggregates, realizing the recycling of resources.

Providing customized services

In order to meet the actual needs of different customers, C150 jaw crusher also provides customized services. Customers can choose different configurations and options according to their specific needs to meet specific production requirements. This flexible and versatile customization service enables the C150 Jaw Crusher to better adapt to a variety of complex working conditions and customer needs.

High performance and extremely reliable C150 jaw crusher Working Principle

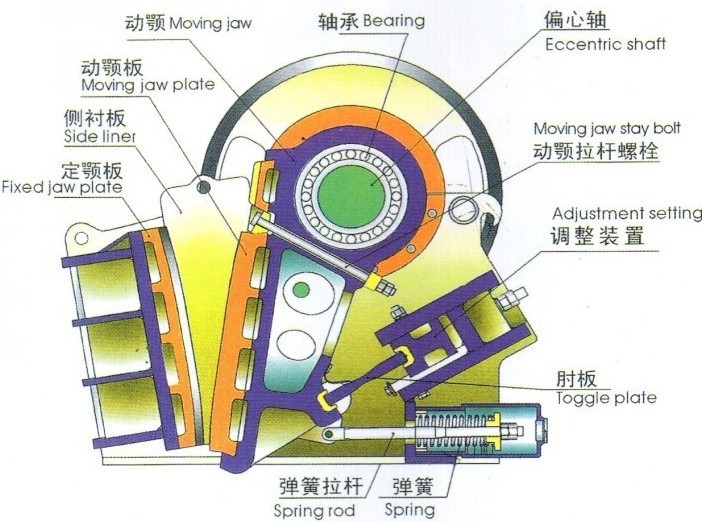

C150 Jaw Crusher, with delicate structure, mainly consists of core parts such as frame, eccentric shaft, big belt pulley, flywheel, side guard plate, elbow plate and its back seat, gap adjusting screw, reset spring, fixed jaw plate and movable jaw plate. When working, the motor drives the belt pulley to rotate and drive the movable jaw plate to reciprocate up and down through the eccentric shaft. When the movable jaw plate rises, the angle between the elbow plate and the movable jaw increases, which pushes the movable jaw plate close to the fixed jaw plate, and the material is crushed by multiple extrusion and rubbing between the two jaw plates. When the movable jaw plate goes down, the angle becomes smaller, the movable jaw plate leaves the fixed jaw plate under the action of pull rod and spring, at this time, the crushed materials are discharged freely from the discharge port in the lower part of the jaw cavity under the action of gravity. With the continuous rotation of the motor, the movable jaw plate moves up and down periodically, realizing the continuous crushing and discharging of materials.C150 Jaw Crusher shows high efficiency and stable crushing performance by virtue of its unique jaw structure and the principle of periodic movement.

High performance and extremely reliable C150 jaw crusher Technical Parameters

| Power | 200 kW | speed | 220 rpm |

| Weight | 50 950 kg | feed opening | 1 400 mm |

| Output Size | 125 mm | Capacity | 500 tph |