GP300S Single Cylinder Hydraulic Cone Crusher

In core industries such as mining, metal smelting, construction and road paving, the fine crushing of raw materials plays an indispensable role. As a leader in the industry, the GP300S single-cylinder hydraulic cone crusher stands out among many crushing equipment with its efficient operation and excellent durability, becoming the first choice trusted by enterprises. This equipment comes from the top domestic machinery manufacturers, combines innovative wisdom and exquisite craftsmanship, and is designed for efficient crushing.

GP300S adopts cutting-edge hydraulic drive technology, combined with a unique single-cylinder structure design, which not only optimizes the overall layout, but also achieves excellent performance of low energy consumption and high output. Its crushed products have uniform particle size to meet diversified production needs. It is particularly worth mentioning that the equipment fully considers the economy of long-term use when designing. By optimizing materials and processes, it ensures low maintenance costs and ultra-long service life, saving a lot of operating costs for enterprises, which is directly converted into considerable economic benefits. Therefore, the GP300S single-cylinder hydraulic cone crusher is not only a technological innovation, but also an ideal partner for enterprises to achieve sustainable development.

GP300S Single Cylinder Hydraulic Cone Crusher Applications

GP300S single-cylinder hydraulic cone crusher has demonstrated extraordinary application value in many key industries with its excellent crushing performance and wide adaptability. The following is an overview of its main application areas and specific roles:

Mining industry: GP300S plays a vital role in the development of mineral resources. It can effectively process a variety of metal ores such as iron ore and copper ore. Through precise crushing operations, it can significantly improve the utilization and recovery rate of ores, and contribute to the economic benefits and efficient utilization of resources in mines.

Construction industry: GP300S is also indispensable in the wave of infrastructure construction. It is widely used in major engineering projects such as road construction, bridges, and tunnels. It efficiently crushes key construction materials such as limestone and granite, ensures the quality and stability of construction materials, and provides a solid foundation for the excellence of engineering quality.

Chemical and silicate industry: In the production process of chemical and silicate products, the crushing and processing of raw materials is a vital link. With its advanced crushing technology and precise control capabilities, GP300S can easily meet the crushing needs of high-hardness raw materials such as quartz and feldspar, provide high-quality, high-purity raw materials for related industries, and promote the continuous advancement and upgrading of industrial technology.

GP300S Single Cylinder Hydraulic Cone Crusher Advantages

Powerful crushing capacity

GP300S single-cylinder hydraulic cone crusher adopts advanced crushing technology and design, with powerful crushing capacity. Its maximum feed opening can reach 332mm (13 inches), and it can handle materials of various hardnesses, such as iron ore, copper ore, limestone, quartz, granite and basalt. By adjusting different eccentric distances (18 to 36mm), it can flexibly cope with raw materials of different particle sizes to ensure the best crushing effect.

Efficient production capacity

The crusher has excellent production capacity and a wide range of output, with a coarse crushing model of 250-870t/h and a fine crushing model of 140-490t/h. This efficient production capacity enables the GP300S single-cylinder hydraulic cone crusher to play an important role in large-scale production lines, significantly improving production efficiency and output.

Precise discharge control

GP300S crusher ensures uniform particle size of crushed materials through precise discharge opening size control. The discharge opening size of the coarse crushing model is generally controlled at 35-100mm, while that of the fine crushing model is controlled at 10-50mm. This precise particle size control not only meets the requirements of different industries for product quality, but also improves the added value of the product.

Reliable overload protection system

In order to ensure the stable operation of the equipment under harsh working conditions, the GP300S single-cylinder hydraulic cone crusher is equipped with a reliable overload protection system. When the equipment encounters unbreakable foreign objects or overload, the system will automatically shut down and alarm, effectively preventing equipment damage and safety accidents.

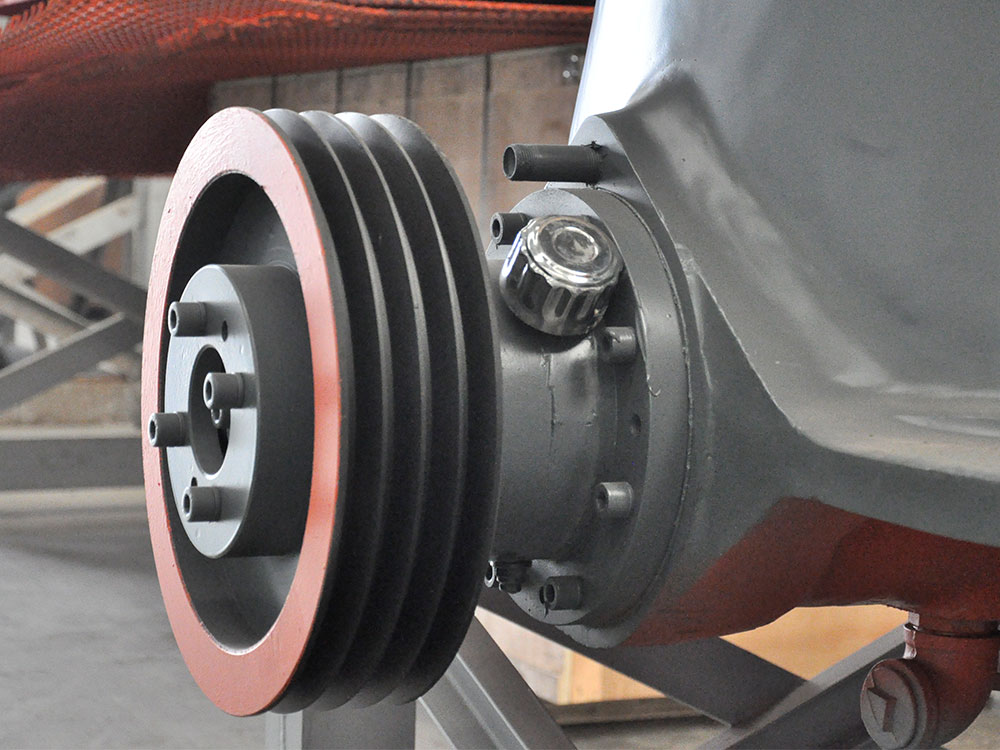

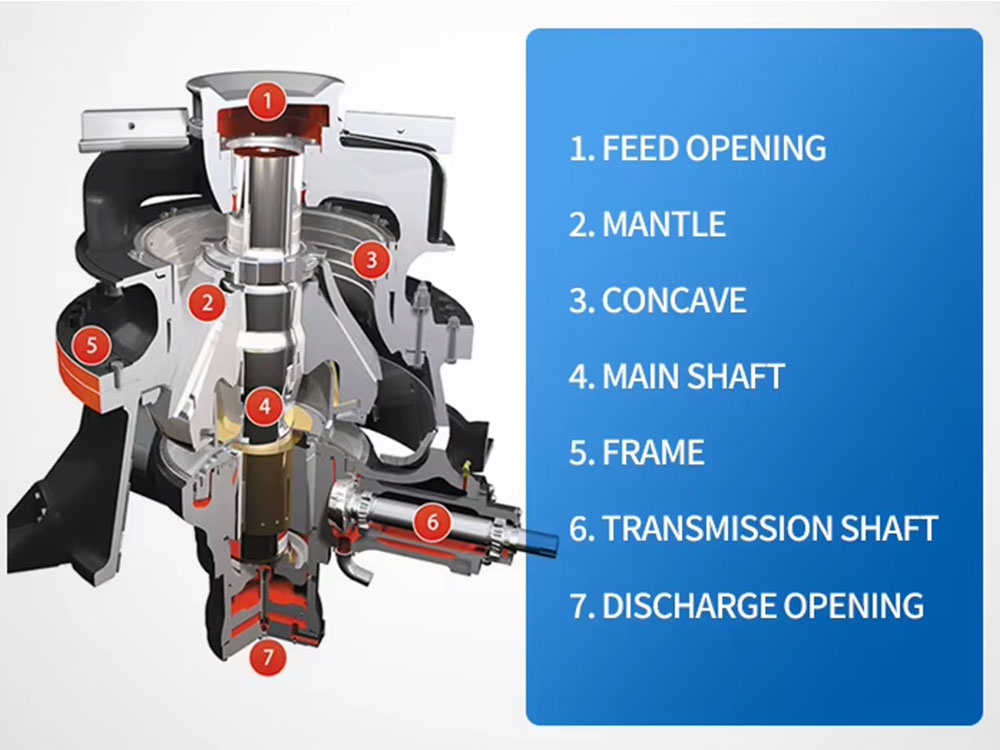

GP300S Single Cylinder Hydraulic Cone Crusher Working Principle

The working principle of the GP300S single-cylinder hydraulic cone crusher is exquisite and efficient. Its core lies in the advanced concept of selective crushing of materials in layers. Specifically, when the material to be crushed is fed into the crushing chamber, the hydraulic device in the system is activated, driving the moving cone to perform complex swinging motion. This motion trajectory cleverly guides the moving cone to apply multiple forces such as extrusion, shearing and kneading to the material, thereby achieving the initial crushing of the material.

As the moving cone continues to swing regularly, the material undergoes a progressive and refined crushing process in the crushing chamber. Larger material blocks are gradually broken down into smaller particles, which gradually move to the discharge port of the crushing chamber under the combined action of gravity and crushing force. Finally, when the particle size reaches the preset standard, they are smoothly discharged from the crusher through the discharge port, completing the entire crushing process.

It is worth mentioning that the design of the GP300S single-cylinder hydraulic cone crusher fully considers the problems of wear and contamination. The wall of its crushing chamber is made of special materials and structural design, which effectively avoids direct contact with the material, thereby significantly reducing the degree of wear and extending the service life of the equipment. At the same time, this design also reduces the risk of contamination caused by friction between materials and metal parts, ensuring the purity and high quality of the crushed products.

GP300S Single Cylinder Hydraulic Cone Crusher Technical Parameters

| Main engine motor power | 250KW | power | 110-160 Read |

| Crusher weight | 16200 kg | Drive mode | Hydraulic |

| Configuration | 1 host, 1 motor, 1 starter cabinet | Discharging | 46-200 mm |