How to choose the appropriate 3642 jaw crusher model

The 3642 jaw crusher is a medium-to-large ore crushing equipment. It is widely used in the coarse crushing of mining, construction, metallurgy and other industries with its high efficiency and stable performance. The feed port size of the equipment is 914×1067 mm, which can handle materials with larger particle sizes. The feed particle size can generally reach 500 to 800 mm, which is particularly suitable for the crushing needs of ores or stones with medium hardness or above. The adjustment range of its discharge port is usually between 75 and 200 mm. By adjusting the size of the discharge port, the discharge particle size can be flexibly controlled to meet the requirements of different production processes. This crusher is made of high-quality high-manganese steel, with a sturdy and durable structural design, and can maintain long-term stable operation in high-intensity operations. Its power system is generally equipped with a high-power motor and an optimized flywheel design, so that the equipment has a stronger crushing capacity and higher work efficiency during the crushing process. In terms of processing capacity, the 3642 jaw crusher can usually reach 200 to 400 tons per hour, which is suitable for the use of medium and large-scale production lines. In addition, the equipment is easy to maintain, and key components such as jaw plates and bearings have a long service life and are easy to replace. Its overall design also focuses on energy conservation and environmental protection, reducing energy consumption while lowering operating costs. It is a popular equipment choice in the modern ore crushing industry.

3642 jaw crusher advantages

Strong feeding capacity and wide application range

The 3642 jaw crusher has a large feed port of 914×1067 mm, which can handle materials from 500 to 800 mm and is suitable for various medium and high hardness ores and stones. This makes it an ideal choice for coarse crushing in industries such as mining, construction, and metallurgy.

Efficient and stable crushing performance

The equipment adopts an optimized crushing chamber design and a powerful power system, equipped with a high-power motor and a scientific flywheel structure, which not only improves the crushing efficiency, but also ensures stability during operation, and can cope with high-intensity operation requirements for a long time.

Flexible discharge adjustment range

The adjustment range of its discharge port is usually between 75 and 200 mm. Users can adjust the discharge particle size according to production needs to adapt to different process requirements. This flexibility makes the equipment more diverse in actual application.

Strong and durable, long service life

The jaw plates and bearings made of high-quality high-manganese steel and other wear-resistant materials have extremely high impact resistance and wear resistance, which greatly extends the service life of the equipment and reduces the cost of frequent replacement of parts.

Easy maintenance and low operating costs

The equipment design focuses on easy maintenance, and the core components are easy to disassemble and replace, reducing downtime. In addition, the optimized energy consumption design enables it to operate efficiently while significantly reducing energy consumption, saving users long-term operating costs.

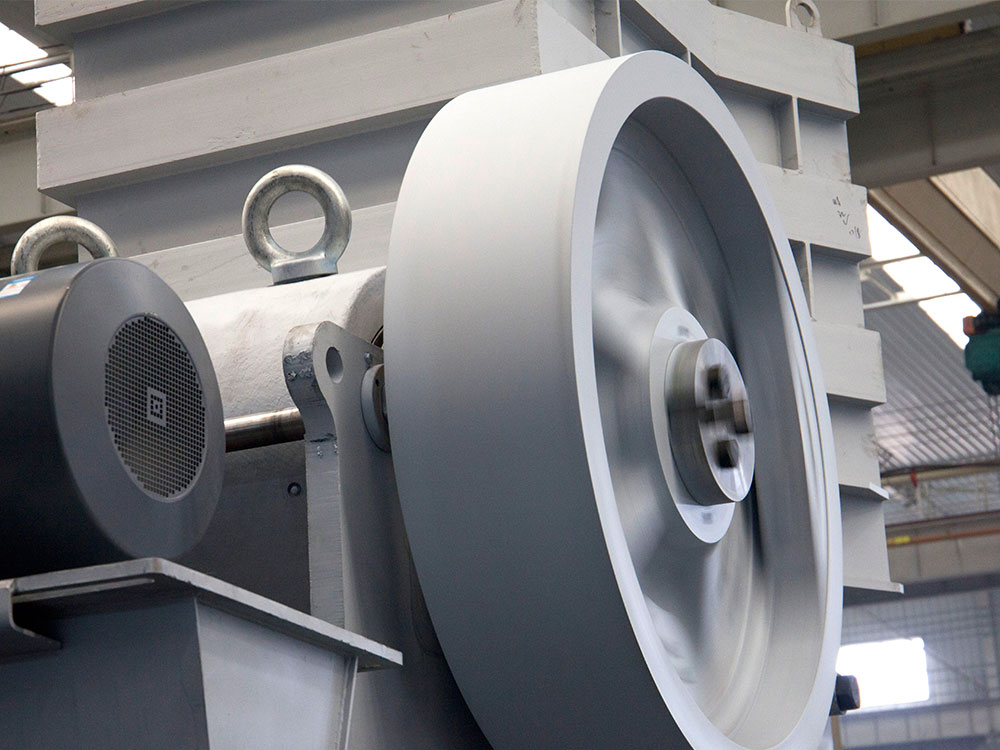

Working principle of 3642 jaw crusher

3642 jaw crusher is a typical coarse crushing equipment, and its working principle is based on the mechanical action of extrusion and crushing. The equipment is mainly composed of fixed jaw plate, movable jaw plate, eccentric shaft, flywheel, frame and adjustment mechanism. When the equipment is started, the motor drives the eccentric shaft to rotate through the belt, driving the movable jaw plate to make periodic reciprocating motion with the fixed jaw plate as the fulcrum. When the movable jaw plate moves forward, the material in the crushing chamber is squeezed between the movable jaw plate and the fixed jaw plate and is gradually crushed; when the movable jaw plate moves backward, the gap in the crushing chamber increases, and the crushed material is discharged from the discharge port under the action of gravity, and new material enters the crushing chamber at the same time, thus completing a crushing cycle. Through continuous reciprocating motion, the equipment realizes continuous crushing of large pieces of ore or stone. The size of the discharge port of the 3642 jaw crusher can be flexibly adjusted through the adjustment mechanism. Users can control the discharge particle size according to production needs to meet different process requirements. The entire crushing process is efficient and reliable. The equipment structure is sturdy and can cope with high-intensity working environments. It is widely used in the coarse crushing process in mining, construction, metallurgy and other fields. It is a crushing equipment with superior performance.

3642 jaw crusher technical parameters

| Output | 200-400t/h | Discharge particle size | 75-200mm |

| Feed port size | 36×42inch | Motor power | 110-15 0kW |

| Feed particle size | 500-800mm | Weight | 20-30t |

3642 jaw crusher case and customer evaluation

In the Potosi region of Bolivia, which is rich in mineral resources, the 3642 jaw crusher is used in silver, zinc and tin mining projects. These ores are hard, and the high wear-resistant jaw plate and strong crushing force of the equipment can efficiently process the ores. It is usually used as a primary crushing equipment to provide suitable materials for subsequent fine crushing and screening. Bolivia has many mountainous areas, and crushing equipment usually needs to face harsh environmental conditions. The 3642 jaw crusher performs well in this environment with its sturdy structure and strong impact resistance. In addition, the easy maintenance of the equipment reduces the difficulty of maintenance in high-altitude operations.

"As a user of the 3642 jaw crusher, I am very impressed by the performance of this equipment. First of all, its processing capacity is indeed satisfactory. Whether it is ore or hard stone, it can efficiently complete the crushing task. The design of the feed port is large, which can easily handle large pieces of material, which is very helpful for us to reduce the workload of preliminary screening."

"I especially appreciate its stable performance. Even after long-term operation, the equipment has not experienced obvious jams or failures. The coordination between the flywheel and the power system is very smooth, and the efficiency of the production line has been greatly improved. The adjustment of the discharge port is also very convenient, and the discharge particle size can be quickly adjusted according to needs. This flexibility makes our production process more worry-free."