How to maximize the benefits of LT106 mobile jaw crusher?

The LT106 mobile jaw crusher is indeed a comprehensive and high-performance device as you said. It is equipped with a variety of optional features, such as side conveyors, vibrating screen modules and extended main conveyors, which greatly improve the flexibility and applicability of the crushing station. At the same time, its automatic control system not only optimizes the crushing effect, but also realizes one-button start and stop, built-in troubleshooting functions and multiple parameter selections, making operation easier and smarter.

The equipment is mounted on crawlers, which gives it excellent maneuverability and can be easily handled in both mining sites and construction sites. In addition, the compact structure also reduces operating costs, allowing users to use resources more efficiently. The LT106 mobile jaw crusher is also equipped with a patented and safe hydraulic fixing system on the feed hopper side. This innovative design enables the equipment to complete the crushing operation or prepare for transportation conditions in a very short time, further improving work efficiency.

LT106 mobile jaw crusher Applications

The LT106 mobile jaw crusher has indeed demonstrated its wide range of applications and excellent performance. In medium-sized aggregate production, it can efficiently crush rocks and ores into aggregates that meet the requirements, ensuring the stable operation of the production line. At the same time, in terms of construction waste recycling, the equipment can also crush discarded concrete, bricks, etc. into recycled aggregates, contributing to the recycling of resources. The LT106 mobile jaw crusher also shines in urban infrastructure construction with its excellent mobility and flexibility. Whether it is road construction or sidewalk paving, it can use crushed concrete as base material, which is both environmentally friendly and economical. In quarries and mines, it can handle all kinds of hard rocks, providing strong support for mining and ore processing. The LT106 mobile jaw crusher can also be used to process other waste materials, such as scrap metal, glass, etc., to maximize the utilization of resources. This versatility makes it a leader in many industries, bringing considerable economic and social benefits to users.

LT106 mobile jaw crusher Advantages

Efficient crushing capacity

The LT106 mobile jaw crusher is specially designed for crushing hard rocks such as granite, basalt and gneiss. Its excellent crushing capacity ensures excellent performance in various applications and fully meets users' stringent needs for efficient crushing.

Flexibility

Thanks to the crawler design, the LT106 mobile jaw crusher can be easily moved within the stope or construction site, and can also be easily transported between different production sites on a low-bed trailer. This high degree of flexibility significantly improves equipment utilization and effectively reduces transshipment costs.

Intelligent control system

The equipment has a built-in advanced automatic control system that supports one-button start and stop. It is also equipped with troubleshooting functions and multiple parameter selections. This intelligent design not only greatly improves the crushing efficiency, but also significantly reduces the difficulty of operation and maintenance costs.

Various optional functions

The LT106 mobile jaw crusher provides a wealth of optional features, including side conveyors, vibrating screen modules and extended main conveyors. Users can flexibly configure it according to actual needs, thereby enhancing the applicability and flexibility of the device.

Compact structure design

The equipment adopts a compact structure design, which not only reduces transportation and installation costs, but also improves the stability and durability of the equipment. At the same time, the compact structure also ensures the safety and convenience of the equipment in daily operations.

Outstanding environmental performance

For densely populated areas such as city centers, schools, and residential areas, the LT106 mobile jaw crusher provides models equipped with noise reduction and dust suppression systems. This model strictly complies with noise and dust management regulations and can carry out crushing operations in areas close to the public, minimizing the impact on the environment.

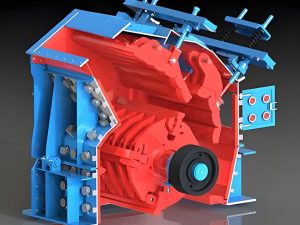

LT106 mobile jaw crusher Working Principle

The working principle of LT106 mobile jaw crusher is mainly based on the mutual extrusion of jaw plates and the periodic movement of the crusher.

When the equipment is working, the motor drives the belt and pulley to rotate, which in turn drives the eccentric shaft to rotate. The rotation of the eccentric shaft causes the movable jaw plate to move up and down periodically. When the movable jaw plate rises, the angle between the toggle plate and the movable jaw gradually increases, pushing the movable jaw plate closer to the fixed jaw plate. At this time, the material between the two jaw plates is gradually crushed by multiple effects such as squeezing and rubbing. When the movable jaw plate descends, the angle becomes smaller, and the movable jaw plate leaves the fixed jaw plate under the action of the pull rod and spring. At this time, the crushed material is freely discharged from the discharge port at the bottom of the jaw cavity under the action of gravity. As the motor continues to rotate, the movable jaw plate moves up and down periodically, thereby realizing continuous crushing and discharge of materials.

LT106 mobile jaw crusher Technical Parameters

| Feed opening | 1,060 x 700 mm | Engine | 224 kW |

| Weight | 40,000 kg | Width | 2,800 mm |

| Height | 3,400 mm | Length | 15,200 mm |