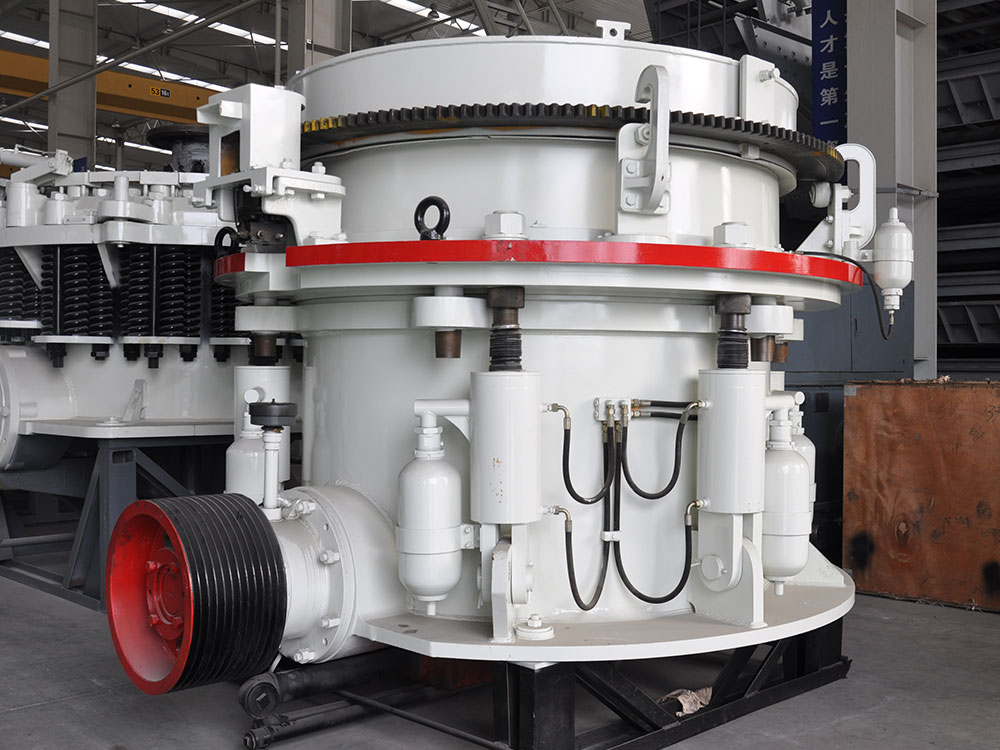

HP400 rock crusher, one of the cone crusher series

HP400 Rock Crusher sets a strict upper limit for feed size - no more than 299mm. This design enables it to easily handle rocks and raw materials of various sizes collected from large open-pit mines to underground mines. Its wide adaptability ensures processing efficiency and flexibility. The discharge size is finely controlled below 30mm, ensuring the uniformity of the crushed products, laying a solid foundation for subsequent processing or direct use. In terms of production capacity performance, HP400 is even more impressive. Its processing capacity spans from 140 to 630 tons/hour, demonstrating strong production potential and significantly improving operating efficiency. In addition, its 315-kilowatt high-power motor provides a solid guarantee for the stable operation of the equipment at full load, further consolidating its leading position in the industry.

HP400 rock crusher Applications

In the face of regions rich in mineral resources, effective crushing of ores has become the first step to extract precious mineral resources and promote efficient use of resources. With its excellent crushing performance, HP400 Rock Crusher can easily overcome the obstacles of ore hardness. Whether it is tough and difficult to break iron ore or ore rich in elements such as copper and zinc, it can be broken down into small pieces under its powerful crushing ability. The cutting-edge crushing technology and carefully designed structure it adopts ensure the stability and durability of the equipment in long-term, high-load operation, effectively control maintenance costs, and improve overall production efficiency.

With the deepening of urbanization, the construction industry has an increasing demand for high-quality building materials. With its wide applicability, HP400 Rock Crusher not only serves the mining industry, but also shines in the crushing and processing of building materials. Whether it is crushed stone used for road construction, high-quality aggregates in concrete production, or even fine sand making materials required for high-end construction, the equipment can provide products with precisely controlled particle size and excellent morphology, fully meet market demand, and provide strong support for the rapid development of the construction industry.

The success of HP400 Rock Crusher is the inevitable result of the deep integration of its technological innovation and sustainable development concept. The built-in automatic control system of the equipment realizes remote monitoring and intelligent adjustment, which greatly improves the convenience and safety of operation. At the same time, the outstanding performance of the equipment in energy saving and consumption reduction, through the optimization of the power system and the adoption of efficient crushing mechanism, effectively reduces energy consumption and emissions, and makes an important contribution to the green development of enterprises.

HP400 rock crusher Advantages

Excellent large-block processing capability

The HP400 Rock Crusher has a feed size limit of ≤299mm, demonstrating its powerful ability to handle large volumes of rock and raw materials, greatly broadening the application field of the equipment. Its discharge particle size is strictly controlled below 30mm, ensuring the uniformity of the crushed product size, which perfectly meets the strict requirements of various engineering projects. In addition, its excellent production capacity of 140-630t/h enables the equipment to efficiently process massive amounts of raw materials per unit time, significantly improving the overall efficiency of the production line.

Efficient and energy-saving power configuration

The HP400 Rock Crusher is equipped with a high-power motor, which provides a solid guarantee for the efficient operation of the equipment. The motor not only has a strong output power, but also achieves the goal of maintaining efficient crushing effect at low energy consumption through advanced energy-saving design, saving users a lot of operating costs. This design not only reflects the technological advancement of the equipment, but also highlights the manufacturer's commitment to environmental protection and sustainable development.

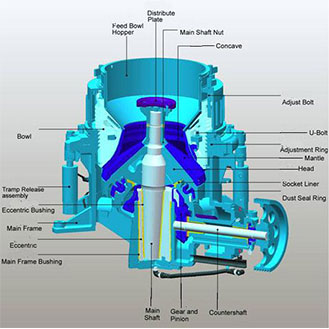

Innovative cone crushing technology

Adopting advanced cone crushing technology, HP400 Rock Crusher achieves efficient and accurate rock crushing by optimizing the crushing cavity and crushing path. Its unique crushing mechanism ensures that the rock is evenly and effectively impacted and squeezed during the crushing process, thereby improving the crushing efficiency and the quality of the crushed product. In addition, the equipment also has an automatic adjustment function, which can intelligently identify the hardness of the rock and the crushing requirements, and automatically optimize the crushing parameters, further improving the intelligence level and operation convenience of the equipment.

Sturdy and durable mechanical structure

HP400 Rock Crusher pursues extreme durability and reliability in mechanical structure design. Key components such as crushing cones and liners are carefully made of high-strength materials, and are processed by precision machining and heat treatment processes to ensure the stable operation and long service life of the equipment under extreme working conditions. At the same time, the equipment is also equipped with advanced lubrication and cooling systems, which effectively reduce component wear and failure rate, further extend the service life of the equipment and reduce maintenance costs.

Convenient operation and maintenance experience

In order to improve the user experience, HP400 Rock Crusher fully considers the convenience of operation and maintenance of the equipment during the design and manufacturing process. The compact and reasonable structure layout makes the maintenance of the equipment easy and simple; the advanced control system and intuitive human-machine interface make the operation of the equipment a piece of cake. Users can start and stop the equipment, adjust parameters and other functions through simple operations, which greatly improves work efficiency and reduces the difficulty of operation.

HP400 rock crusher Principle

HP400 Rock Crusher mainly uses a conical crushing chamber and a rotating crushing cone to crush ores. Its working principle is based on the "laminated crushing" theory, that is, the ore is crushed in the crushing chamber under the action of multiple forces such as extrusion, shearing and bending. The crushing chamber of HP400 Rock Crusher consists of an upper fixed cone and a lower moving cone. The gap between the two is adjustable to meet the crushing needs of ores of different particle sizes and hardness. The shape and size of the crushing chamber are precisely designed to ensure that the ore can be subjected to uniform pressure distribution during the crushing process, thereby improving the crushing efficiency and product quality. The moving cone is driven to rotate by the motor through the transmission device. During the rotation, the cone surface of the moving cone constantly approaches the cone surface of the fixed cone, forming a gradually shrinking crushing space. After the ore is fed into the crushing chamber, it is subjected to the strong extrusion and shearing between the moving cone and the fixed cone, and gradually crushed into smaller particles. During the crushing process, the ore is first hit and squeezed by the moving cone, and then with the rotation of the moving cone, the ore is brought deeper into the crushing chamber and further subjected to shearing and bending. The combined effect of these forces causes the ore to be gradually broken into the required particle size. At the same time, a discharge port is also provided in the crushing chamber, and the crushed ore is discharged from the crusher through the discharge port.

HP400 rock crusher Technical Parameters

| Motor Type | AC motor | weight | 10000 KG |

| Core Components | PLC, pressure vessel, gear, motor, engine | After Sales Service | The whole time |

| Dimensions (length x width x height) | According to machine model | Spare Parts Supply | Will Supply Any Time |

| Test&Installation | Professional Engineer Assigned | Guarantee/Warranty | one year excluding wearing parts |