Looking for reliable crushing equipment?CJ615 Jaw Crusher is your best choice!

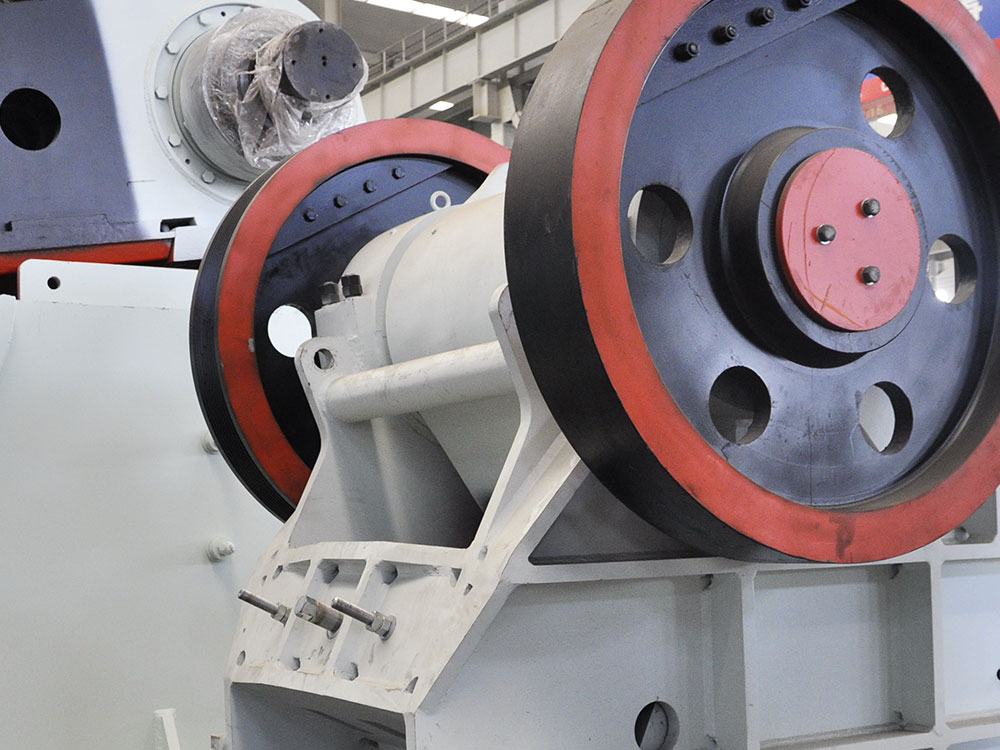

The CJ615 jaw crusher is a single elbow compound pendulum model with a deep and symmetrical crushing chamber and optimised meshing angle. This design results in smooth material fall and high crushing efficiency, while achieving high operating rate, large crushing ratio and high capacity. Its large feed opening can handle larger feed materials, further enhancing the crushing capacity. The crusher pays attention to detail design, such as adopting a grease lubrication system and a centralised lubrication distributor to ensure safe and convenient bearing lubrication. In addition, it is equipped with an automatic lubrication system that can be connected to the existing control system for remote alarm indication to better protect the roller bearings.

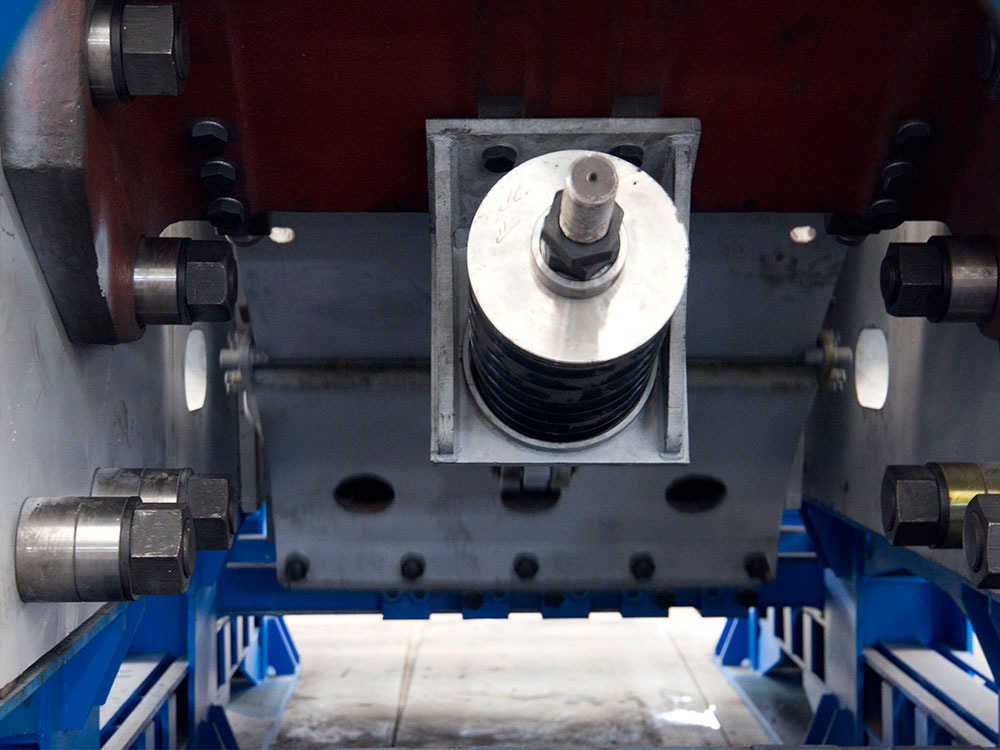

In terms of discharge opening settings, the CJ615 Jaw Crusher offers a variety of adjustment methods, including traditional shim adjustment, hydraulic-assisted adjustment and wedge-block hydraulic adjustment, to meet the needs of different users. Its welded frame body ensures equal strength in all directions and excellent durability against shock loads. The crusher also adopts a quick mounting method to fix the jaw plate on the crusher, and the use of some protective parts effectively avoids the damage of the main parts, reduces the total cost of the equipment life cycle and improves the operation rate.

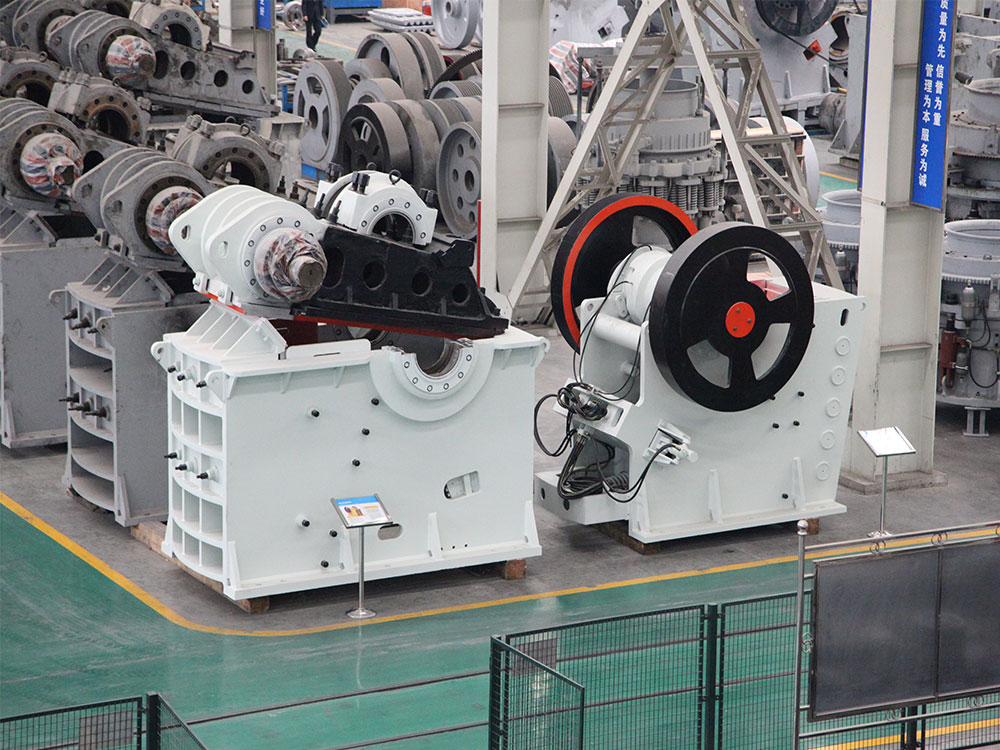

The CJ615 jaw crusher is designed and manufactured with a focus on long life, low wear and easy maintenance. Its low jaw wear reduces the need for maintenance, which in turn reduces downtime and allows users to benefit from the high productivity levels of the plant for longer. The crusher is the best choice for applications requiring high productivity and low total cost of ownership, and is widely used in a wide range of industries including mining, metallurgy, building materials, highways, railways and chemicals.

CJ615 Jaw Crusher Applications

With its robust structure, efficient crushing performance and wide applicability, the CJ615 Jaw Crusher is the ideal choice for coarse and medium crushing operations in many industries. The following is a list of its main application industries:

1、Metal Mining: CJ615 Jaw Crusher can efficiently crush iron ore, copper ore, gold ore and other metal ores, and provide suitable feed size for the subsequent beneficiation process. Non-metallic mining: In the mining process of limestone, granite, basalt and other non-metallic minerals, CJ615 jaw crusher also performs well, and its strong crushing capacity can easily deal with high hardness materials.

2, sand and gravel aggregate production: CJ615 jaw crusher is the core equipment in the sand and gravel aggregate production line, which can crush the large stone into different specifications of crushed stone, used in concrete mixing, road construction and so on. Construction Waste Disposal: With the acceleration of urbanisation, the disposal of construction waste has become a big problem, CJ615 Jaw Crusher can crush the construction waste into recycled aggregates to achieve the recycling of resources.

3、Steel slag processing: steel slag is a solid waste produced in the process of iron and steel production, CJ615 Jaw Crusher can crush it into fine particles for the production of steel slag cement, paving materials and so on. Refractory processing: Some refractory materials need to be crushed for subsequent processing, CJ615 jaw crusher can provide stable and reliable crushing solutions.

CJ615 Jaw Crusher Advantages

Sturdy and durable, stable and reliable

CJ615 Jaw Crusher adopts high-strength cast steel frame and high manganese steel jaw plate, which ensures the stable operation of the equipment even when crushing high hardness materials. Advanced processing technology and strict quality control ensure that all parts of the equipment are highly accurate and closely matched, effectively extending the service life of the equipment. Optimally designed structure and reliable parts make CJ615 jaw crusher able to operate stably for a long time under the harsh working conditions, reduce the failure rate and improve the production efficiency.

High efficiency and energy saving, excellent output

The deep crushing chamber and reasonable meshing angle design increase the crushing ratio and improve the crushing efficiency, so that the materials are fully crushed in the crushing chamber. Larger crushing stroke, so that the material in the crushing cavity by a greater impact force, improve crushing efficiency, increase production. Optimised design of structure and movement parameters reduces the energy consumption of the equipment during operation, reduces the production cost of the user and meets the requirements of environmental protection at the same time.

Easy maintenance and low cost

The key components adopt modular design, which is easy to disassemble and replace, reducing downtime and maintenance cost. Adopt centralised lubrication system, which is convenient for users to lubricate and maintain the equipment, and prolong the service life of the equipment. Humanised operation interface and simple operation process, even novice can quickly get started, reduce the operating difficulty.

Wide application and strong adaptability

CJ615 Jaw Crusher provides a variety of specifications and models to meet the production needs of different users. It can crush materials of various hardness, including granite, basalt, limestone, iron ore, etc. It is widely used in mining, construction, metallurgy, chemical industry and other industries. According to the actual needs of users, flexible configuration of feeding equipment, conveying equipment, etc., to form a complete crushing production line.

Intelligent control, safe and reliable

PLC control system can be optional to achieve automatic control of the equipment, improve production efficiency and safety. Equipped with overload protection device, alarm system, etc., to ensure the safe and reliable operation of the equipment, to protect the safety of operators.

CJ615 Jaw Crusher Working Principle

When the motor is started, the eccentric shaft starts to rotate through the belt and pulley drive. The rotation of the eccentric shaft drives the movable jaw to swing periodically around the suspension axis. The trajectory of the movable jaw appears as an up-and-down reciprocating arc. When the movable jaw is close to the fixed jaw, the material located between the two jaw plates is subjected to the combined effects of extrusion, splitting and bending. At the beginning, the pressure gradually increases, so that the volume of the material is reduced, and the materials are close to each other and squeezed. When the pressure rises to more than the strength of the material can withstand, the material is broken. When the movable jaw leaves the fixed jaw and swings in the opposite direction, the material in the crushing chamber moves downward by its own weight. Materials smaller than the size of the discharge opening are discharged from the discharge opening, while the incompletely crushed materials continue to stay in the crushing chamber, waiting for the next extrusion and crushing by the movable jaw. Every cyclic movement of the movable jaw causes the material to be crushed once and discharged downwards for a certain distance. After a number of cycles, the crushed material is gradually discharged from the discharge opening.

CJ615 Jaw Crusher Parameters

| Capacity | 300-1000 t/h | Feed opening | 1,500 x 1070 mm |

| power | 200 kW | Weight | 56,500 kg |

| Feed size | 960.000 mm | range | 115.0 - 300.0 mm |