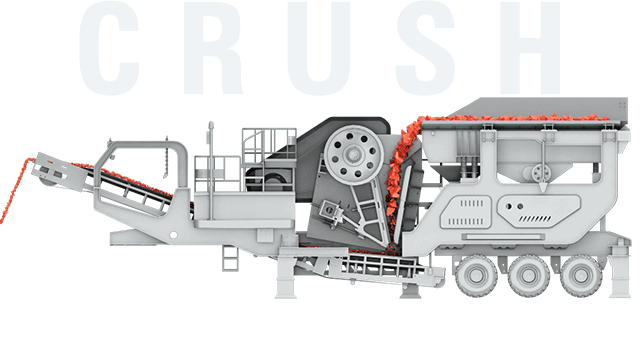

LT130E mobile crusher is a new choice for coarse crushing in mines

LT130E mobile crusher is widely used in many fields, including mining, construction, highway, railway, etc., for crushing and processing of ore and rock. It can handle ores of various hardness, such as granite, river pebbles, iron ore, etc. It is also suitable for crushing and recycling construction waste, contributing to environmental protection.

Before starting the equipment, be sure to check whether all parts are intact, whether the fasteners are loose, whether the drive belt is worn or broken, and whether the lubrication system is normal. The electrical system also needs to be carefully checked to ensure that the cables are not damaged and that safety devices such as leakage protectors and short-circuit protectors are operating normally.

During the operation of the equipment, the operator should pay close attention to its status. Once abnormal sound or vibration is found, the machine should be stopped for inspection immediately. It is strictly forbidden to overload the equipment. When the load is too large, the feed rate should be appropriately reduced or the machine should be stopped for processing.

To extend the service life of the LT130E mobile crusher and keep it in good condition, the operator needs to perform regular maintenance. This includes checking the wear of fasteners and transmission parts, the smoothness of the lubrication system, and regularly replacing severely worn parts and replenishing or replacing lubricating oil.

LT130E mobile crusher is a new choice for coarse crushing in mines Applications

In the field of infrastructure construction, the LT130E mobile crusher has indeed played an important role. It can process raw materials into particle sizes that meet the requirements, provide high-quality aggregates and sand and gravel for highways, railways, water conservancy projects, and lay a solid foundation.

With the acceleration of urbanization, the treatment of construction waste has become a problem. LT130E shines in the treatment of construction waste with its excellent crushing capacity and flexibility. It can crush garbage into different particle sizes for the production of recycled concrete, recycled bricks, etc., to achieve resource utilization.

In the field of mining, the LT130E mobile crusher also performs well. It can easily cope with various hardness ores, such as granite, basalt, gneiss, etc., to achieve efficient and uniform crushing. In open-pit mines and large quarries, LT130E can be used as a link of multi-stage combined crushing or a separate primary crushing equipment to provide strong support for mining.

LT130E mobile crusher is a new choice for coarse crushing in mines Advantages

High-efficiency crushing capacity

The LT130E is equipped with a C130 jaw crusher, which is particularly suitable for crushing hard rocks such as granite, basalt and gneiss. Its 1,000mm deep feed port can accommodate larger pieces of material, which greatly reduces the use requirements of blasting and breaker.

Excellent mobility

Despite its large size, the LT130E is very convenient for transfer and transportation. It can quickly enter the crushing site and save valuable time. As a mobile crusher, it has high mobility and can adapt to various complex terrain conditions and flexibly respond to different operating environments.

Integrated design and low-cost operation

The LT130E adopts an integrated unit equipment installation form, eliminating the complicated site infrastructure installation work of the split components, reducing the consumption of materials and man-hours. It can process materials on site without moving the materials off site for reprocessing, which greatly reduces the transportation cost of materials.

Environmental protection and intelligent features

LT130E may be equipped with a high-efficiency dust collector and an intelligent control system (depending on the actual configuration), which helps to achieve an environmentally friendly and worry-free working environment and improve working efficiency and flexibility. Its design also takes environmental protection requirements into consideration, such as good sealing effect, professional dust removal and noise reduction devices, etc., to reduce the impact on the environment.

Versatility and flexibility

LT130E can be used as part of a multi-stage combined crushing system or as a single primary crushing system, providing flexible process configuration options to meet the diverse processing needs of users. According to different production needs, the mobile crusher can also be customized to adapt to different crushing tasks.

LT130E mobile crusher is a new choice for coarse crushing in mines Working Principle

The LT130E mobile crusher is equipped with a high-performance C130 jaw crusher. It adopts the principle of jaw crushing and applies pressure to the material through two working jaw plates. When the compressive stress of the material exceeds its compressive strength, crushing occurs. Its 1,000mm deep feed opening can easily accommodate large pieces of material into the crushing chamber. Under the continuous extrusion and grinding of the jaw plate, the material is gradually broken into smaller particles. This design not only improves crushing efficiency, but also significantly reduces the need for blasting and breaker hammers. In addition, the jaw plate of the LT130E is well designed with excellent engagement angle and dynamic performance to ensure efficient crushing in various rock crushing processes. At the same time, the crusher can be used as a part of a multi-stage crushing system or as a primary crusher alone, providing users with great flexibility to meet diverse processing needs.

LT130E mobile crusher is a new choice for coarse crushing in mines Technical Parameters

| feedthrough | 1,300 x 1,000 mm | motor | 403 kW |

| Crusher motor | 185 kW | alternators | 420 kVA |

| weights | 105,000 kg | breadth | 3,500 mm |

| high degree | 3,900 mm | lengths | 21,500 mm |