LT7150 mobile VSI crusher designed for final stage crushing

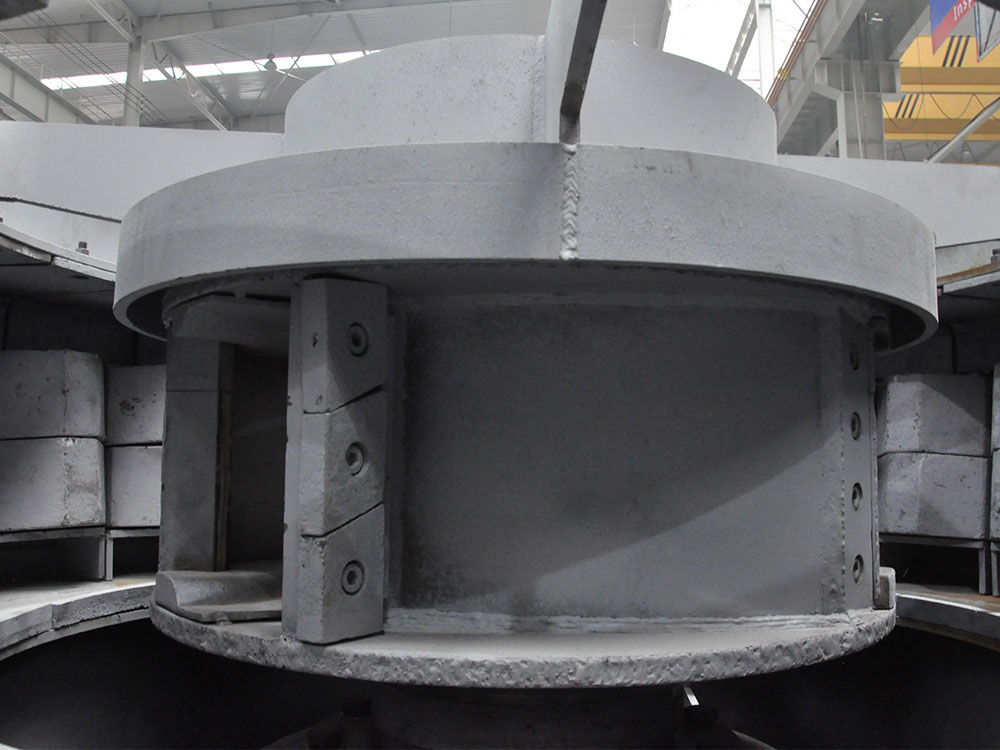

The series of countershaft impact crushers (sand making machines) produced by our factory are the result of optimized design and manufacturing combined with advanced domestic and foreign technologies. This series of equipment works stably and reliably, is easy to maintain, and has high sand making efficiency. The particle shape of its output products is regular, with obvious cubic shape and extremely low needle and flake content. It is very suitable for stone shaping and the production of machine-made sand. It is a high-quality finished product for industries such as hydropower, highways, construction, cement and metal mining. Ideal choice for materials. The VSI series vertical shaft impact crusher integrates precise manufacturing and excellent design. It is equipped with a PLC control system, which realizes friendly interaction with the human-machine interface, simplifies the operating process, and reduces the training time for operators. The VSI LT7150 mobile crusher uses a vertical shaft impact crusher as the core and uses "stone on stone" crushing technology to produce high-quality cubic aggregates, road construction base materials and machine-made sand. It is especially suitable for the final crushing stage and is widely used. In the fields of construction, mining and other fields, it shows the characteristics of high efficiency, environmental protection and flexibility.

LT7150 mobile VSI crusher Applications

Hydropower Industry: For large-scale projects such as hydropower station dams and spillways, efficient shaping equipment can produce cubic stones that meet strict standards to ensure the stability and durability of the engineering structure.

Highway and Transportation: In the construction of transportation infrastructure such as highways and railways, the high-quality sand and cubic stones provided by machine-made sand production equipment are the key to improving road surface quality and extending service life.

Construction Industry: Cubic-shaped stones are used in high-rise buildings, commercial complexes and other projects, which not only enhance the mechanical properties of the building structure, but also improve the aesthetics of the building.

Cement and Concrete: As the aggregate of cement and concrete, cubic stones can significantly improve the strength and durability of the material and are the cornerstone of high-quality cement products.

Metal Mine: During the processing of metal ore, shaping equipment can optimize the particle shape of the ore and improve smelting efficiency and product quality.

LT7150 mobile VSI crusher Advantages

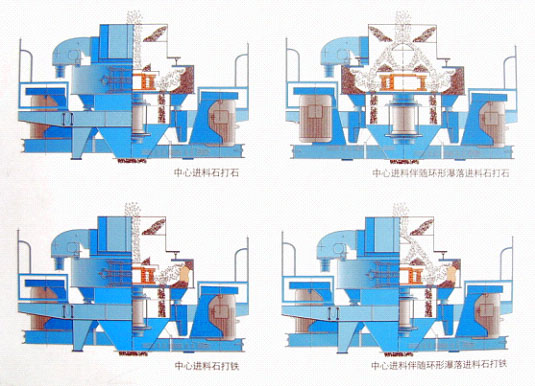

Flexible feeding mode

The equipment can easily switch between full center feeding and center plus waterfall feeding, and also supports the switching between "stone hitting stone" and "stone hitting iron" modes, realizing multiple uses of one machine to meet the diverse needs of users from stone crushing to shaping.

Controllable fineness modulus and high-quality products

The fineness modulus can be flexibly adjusted to ensure that the product particles have excellent shape, obvious cubic shape, extremely low needle-like content, high bulk density, balanced gradation, and extremely low iron pollution. It is very suitable for aggregate shaping, artificial sand making and high-grade highway aggregate production.

Innovative impeller design improves efficiency

Through the optimized launch port structure and the smooth material flow curve inside the impeller, the material flow resistance is reduced, the material throughput and crushing ratio are increased, thereby improving production efficiency, optimizing particle shape, and increasing output, while reducing maintenance costs.

Green and low pollution

The equipment is equipped with a unique air circulation system, which greatly reduces the external exhaust volume and reduces dust pollution, meeting environmental protection requirements. In addition, the reserved position of the crusher facilitates the installation of dust removal equipment of various specifications, further reducing environmental pollution.

LT7150 mobile VSI crusher Principle

Based on the advanced selective crushing and cleavage crushing principle, the equipment directly applies sufficient kinetic energy to the material and converts this kinetic energy into the energy required to crush the material through impact. The material is mainly broken along its natural texture and cleavage plane, forming a high-quality particle shape, while reducing the self-consumption of the equipment. The equipment can realize the conversion of the two working modes of "stone hitting stone" and "stone hitting iron". During the crushing process, the material falls vertically from the top of the machine into the high-speed rotating impeller, and is subjected to strong centrifugal force, and collides with another part of the material dispersed around the impeller in an umbrella shape at high speed, thereby achieving preliminary crushing. Subsequently, these materials form a vortex between the impeller and the casing, and undergo multiple collisions and frictions to further refine. Finally, the material is discharged vertically from the bottom of the equipment, forming a closed-loop multiple circulation. Through screening by the screening equipment, the finished product particle size that meets the requirements can be obtained.

LT7150 mobile VSI crusher Principle Parameters

| Max feed size | 75 mm (2¼'') | Engine | CAT®, 310 kW (415 hp) |

| Weight | 30,000 kg (66,000 lbs) | Width | 3,000 mm (9'10") |

| Height | 3,400 mm (11'1") | Length | 16,750 mm (54'11") |