Medium-sized B7150SE crusher for sale

The B7150SE crusher indeed shines in many fields such as construction, industrial minerals, metal minerals and solid waste recycling due to its significant advantages of high efficiency, energy saving and easy maintenance. This crusher is known for producing high-quality cubic final products and low operating costs. It is good at processing rocks, recycled materials, ores and minerals. Through the ingenious design of the feed materials colliding with each other, it achieves self-crushing and outputs The product has uniform grain shape and obvious cubic shape. At the same time, the product has lower water content and excellent quality.

In addition, the B7150SE crusher can be flexibly equipped with metal anvils according to actual customer needs, thereby significantly increasing the crushing ratio and producing finer final products to meet diversified production needs. The choice of multiple models, including fixed, portable and mobile, allows it to easily meet the challenges of different scenarios.

In terms of energy saving, the B7150SE crusher also performs well. Its wear rate is low, which effectively extends the maintenance and repair cycle, increases the operating rate, and brings more considerable economic benefits to users. At the same time, the equipment is equipped with an automatic lubrication system and a design that allows quick maintenance of the rotor through the access door, which greatly shortens maintenance downtime and improves the overall operating efficiency of the equipment.

It is worth mentioning that the B7150SE crusher can also be connected to the IC crusher automatic system to achieve intelligent operation. This innovative design undoubtedly brings a qualitative leap to the equipment's operational convenience and intelligence level.

Medium-sized B7150SE crusher for sale Applications

The B7150SE crusher is popular in aggregate production due to its ability to produce a final product with excellent particle size. It can process rocks and ores of various hardnesses and crush them into aggregates that meet the requirements for use in the construction of buildings, roads, bridges and other infrastructure.

In the construction industry, the B7150SE crusher can be used to prepare raw materials for concrete, asphalt and foundation materials. The crushed materials have uniform particle size and low moisture content, making them very suitable for use as building materials.

In the field of recycling, the B7150SE crusher can crush discarded concrete, bricks and other construction waste into recycled aggregates to achieve resource recycling. This not only helps reduce environmental pollution caused by construction waste, but also saves raw materials and energy.

The B7150SE crusher can also be used for industrial mineral processing, such as grinding feed, heap leaching process, etc. Its efficient crushing capacity and precise particle size control give this equipment significant advantages in the field of industrial mineral processing.

The B7150SE crusher is also suitable for crushing metal minerals, such as iron ore, copper ore, etc. Its sturdy structure and wear-resistant components enable the equipment to cope with harsh working conditions and long-term operating requirements.

Medium-sized B7150SE crusher for sale Advantages

High crushing efficiency

The B7150SE crusher adopts a unique vertical shaft impact crushing principle, which uses the feed materials to collide with each other and crush themselves, with high crushing efficiency. The equipment can handle rocks and ores of various hardnesses, and the crushed materials have uniform particle size, meeting a variety of production needs.

Low cost

Compared with other types of crushers, the B7150SE crusher has a lower operating cost. Its rock-on-rock working principle reduces the cost of wear parts, and the equipment is easy to maintain, reducing the overall operating cost. At the same time, the equipment is equipped with automatic lubrication systems and inspection doors, which further extend the service life of the equipment and reduce downtime.

Flexible and adjustable

The performance of the B7150SE crusher can be fine-tuned according to actual needs. By changing the rotor speed or waterfall flow ratio, operators can optimize output and power consumption, and control product grading and particle shape to meet technical specifications. This flexibility allows the B7150SE crusher to adapt to different production environments and material characteristics.

Energy saving and environmental protection

When the B7150SE crusher is equipped with a traditional rock-on-rock crushing chamber ring, due to the mutual collision of rocks, the crushing circuit requires less energy, and the energy saving effect is significant. At the same time, the equipment generates low noise and dust pollution during operation, which meets environmental protection requirements.

Wide application fields

The B7150SE crusher is widely used in aggregate production, construction industry, recycling, industrial mineral processing and other fields. Its excellent performance and stable performance make this equipment the preferred equipment in many industrial fields.

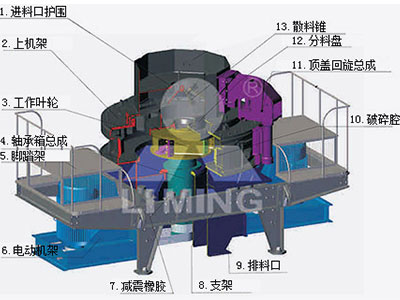

Medium-sized B7150SE crusher for sale Working Principle

The B7150SE crusher mainly uses the feed material in the crushing chamber to self-crush, which is called the rock-on-rock working principle. During the crushing process, the feed material first enters the rotor, which rotates at high speed, accelerates the material and throws it onto the wall of the crushing chamber or other materials. The material is crushed by colliding with each other and hitting the wall, forming a final product with uniform particle size.

In addition, the B7150SE crusher can also be equipped with metal anvils according to customer requirements. In this case, the rock-on-rock crushing chamber ring is replaced by anvil rings, and the rock impact acts on the metal anvil instead of the rock material lining. The anvil solution can increase the crushing ratio and produce a finer final product. However, it should be noted that materials with high abrasiveness need to replace the anvils from time to time, so the wear cost will be slightly higher.

In addition to the above crushing principle, the B7150SE crusher also has a waterfall flow feature. The material can bypass the rotor overflow into the crushing chamber. This feature allows operators to optimize production and power consumption, and control product grading and particle shape to meet different technical specifications.

Medium-sized B7150SE crusher for sale Technical Parameters

| weight | 12 400 kg | Power | 160 - 320 kW |

| feed size | 45 mm | Speed | 1 100 - 2 100 rpm |

| Minimum capacity | 137 Mtph | cascade | 545 Mtph |