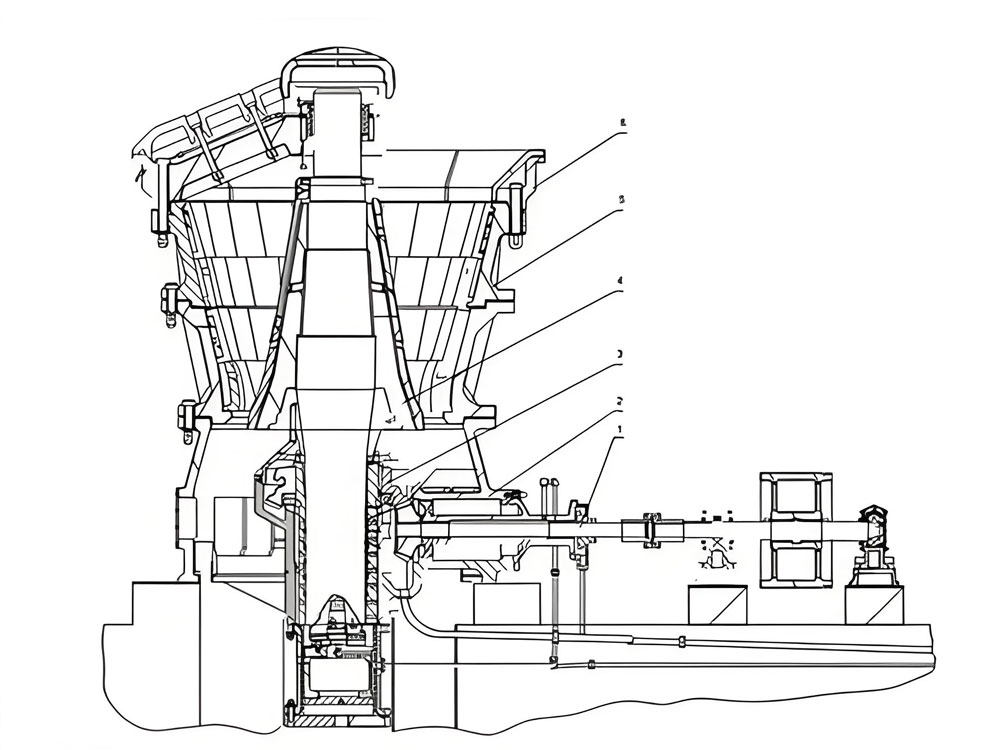

Mobile crushing unit UH316 cone crusher

UH316 cone crusher stands out in the crushing equipment market with its excellent performance and flexible application. Its core component adopts the advanced CH430 cone crusher. This design not only ensures the high efficiency and stability of the equipment, but also brings long-term reliable use guarantee to users. In the design of the main shaft, UH316 adopts a hydraulic adjustment structure with upper and lower two-point support. This design greatly enhances the force stability of the main shaft, allowing the equipment to withstand greater loads during crushing operations, while ensuring the smooth progress of the crushing process. In addition, combined with the constant crushing chamber (CLP) design, the equipment can maintain the stability of processing capacity and discharge particle size during the liner wear cycle, thereby ensuring the uniformity and consistency of the crushed products.

The adjustability of cavity type and eccentricity is another highlight of the equipment. UH316 supports 4 eccentric sleeve configurations. Users can choose the appropriate cavity type and eccentricity according to different crushing requirements (such as medium crushing or fine crushing), so as to achieve precise control of the crushing effect. This flexibility enables the equipment to be widely used in various crushing scenarios to meet the needs of different users. Based on the crawler chassis design, the UH316 cone crusher has excellent mobility and adaptability. It integrates multiple functional modules such as the crushing host, vibrating screen and conveyor, and can be quickly deployed to quarries, mines and other scenes to meet the needs of mobile operations. At the same time, its compact structural design facilitates site conversion, reduces infrastructure costs, and brings more economic benefits to users.

In terms of processing capacity, the estimated output of the UH316 cone crusher is 250 tons/hour (depending on the hardness of the material and the cavity configuration). This efficient processing capacity enables the equipment to easily cope with large-scale crushing operations, saving time and cost for users. At the same time, it is suitable for the crushing of medium-hardness materials such as granite and basalt, and can produce high-quality finished products such as railway ballast and water-stabilized layer aggregates, further broadening the application field of the equipment. The UH316 cone crusher also adopts a modular design. Users can customize the parameters of the vibrating screen and motor according to actual needs, thereby improving the adaptability and flexibility of the production line. This design not only meets the personalized needs of users, but also provides convenience for equipment upgrades and maintenance.

Mobile crushing unit UH316 cone crusher Applications

In the field of metal mining, the UH316 cone crusher is suitable for the secondary and fine crushing of medium and high hardness metal ores such as iron ore and copper ore. Its powerful crushing capacity and precise particle size control can meet the strict requirements of the beneficiation process for material particle size, thereby improving beneficiation efficiency and reducing production costs. By optimizing the crushing chamber type and eccentricity configuration, the equipment can effectively crush ores of different hardness and provide high-quality raw materials for subsequent smelting and processing.

For the treatment of non-metallic ores such as granite, basalt, and limestone, the UH316 cone crusher also performs well. It can crush these ores into finished products with stable particle size, providing a high-quality source of raw materials for building aggregates, cement raw materials, etc. The constant crushing chamber design and adjustable eccentricity function of the equipment enable it to maintain a stable processing capacity and output particle size during the crushing process, thereby ensuring the quality stability and consistency of the finished product.

In the sand and gravel production line, the UH316 cone crusher can be integrated into the system and used in conjunction with screening equipment for cyclic crushing. By precisely controlling the crushing cavity and adjusting the eccentricity, the equipment can produce sand and gravel aggregates that meet engineering standards and provide high-quality building materials for road construction, bridge construction, etc. Its efficient processing capacity and stable finished product quality make the sand and gravel production line more efficient and reliable.

In the field of construction aggregate processing, the UH316 cone crusher can provide sand and gravel raw materials of uniform particle size for concrete, water-stabilizing layer, etc. These raw materials have excellent physical properties and chemical stability, which can ensure the strength and durability of building structures. By optimizing the crushing cavity and adjusting the crushing parameters, the equipment can meet the requirements of different construction projects for aggregate particle size and quality.

In railway and road construction, the UH316 cone crusher can crush hard stones such as granite to produce engineering materials such as railway ballast and roadbed fillers that meet standards. These materials have the characteristics of high strength and wear resistance, which can meet the high requirements of railways and roads for basic materials. Through the crushing treatment of this equipment, the quality and stability of engineering materials can be ensured, and the service life and safety of railways and roads can be improved.

In the field of water conservancy projects, the UH316 cone crusher is involved in the crushing of stones for infrastructure such as dams and channels. It can crush high-quality stones that meet the needs of water conservancy projects for high-strength aggregates. These stones have excellent compressive strength and durability, which can ensure the stability and safety of water conservancy projects. Through the crushing process of this equipment, high-quality aggregate resources can be provided for water conservancy projects, promoting the sustainable development of water conservancy projects.

In the metallurgical industry, the UH316 cone crusher can crush and reuse by-products such as metallurgical slag. Through crushing, these by-products can be converted into valuable resources, promoting the recycling and sustainable development of resources. The powerful crushing capacity and flexible adjustment function of this equipment enable it to adapt to the crushing needs of different metallurgical auxiliary materials.

With its crawler chassis and modular design, the UH316 cone crusher can quickly adapt to the needs of mobile operations such as quarries and temporary construction sites. Its compact structural design and efficient crushing capacity enable the equipment to be quickly converted between different sites, reducing infrastructure costs and improving equipment utilization and economic benefits. This mobile operation capability makes the UH316 cone crusher have broad application prospects in many fields.

Mobile crushing unit UH316 cone crusher Advantages

High-efficiency crushing capacity and intelligent control

The UH316 cone crusher is unique in the crushing industry for its excellent high-efficiency crushing capacity and advanced intelligent control technology. Its core component adopts the advanced CH430 cone crusher. This design not only ensures the efficient operation of the equipment, but also brings long-term reliable use guarantee to users. The adjustable eccentricity and constant crushing chamber (CLP) design enable the equipment to maintain the stability of the output particle size during the liner wear cycle, thus meeting various process requirements such as medium crushing and fine crushing.

It is particularly worth mentioning that the UH316 cone crusher has significantly improved its feed processing capacity by adopting an "S"-shaped cone structure compared with the standard model, with an increase of up to 90%. This design enables the equipment to efficiently produce high-standard finished products such as railway ballast and water-stabilized layer aggregates, providing high-quality raw materials for infrastructure construction.

In terms of intelligent control, the UH316 cone crusher is equipped with the ASRi™ intelligent control system. The system can monitor the load and discharge port size of the crusher in real time, and automatically adjust the operating parameters according to the monitoring data to maintain the best working efficiency of the equipment. At the same time, the wear data of the liner is intuitively fed back through the display screen, so that users can understand the status of the equipment in time and perform necessary maintenance and replacement.

In addition, the equipment is also equipped with an automatic level sensor, which can accurately control the feeding speed and effectively avoid the occurrence of equipment overload or idling, thereby reducing energy consumption and improving the overall economy of the equipment.

Modular system and mobility advantages

The modular system design of the UH316 cone crusher brings great convenience to users. Based on the design of crawler chassis, the equipment integrates the crushing host, screening and conveying modules, and can be quickly put into operation without fixed infrastructure. This feature makes the UH316 particularly suitable for temporary construction sites or mining projects with limited sites, greatly shortening the construction period and reducing infrastructure costs.

At the same time, its compact structural design shortens the wheelbase and reduces the turning radius, allowing the equipment to move flexibly in complex terrain to meet the needs of various complex working environments.

In terms of the lubrication system, the UH316 cone crusher adopts a dual oil pump (one for use and one for backup) and a double-barrel oil filter design. This design enables the equipment to be switched and maintained without stopping, greatly improving the reliability and stability of the equipment. At the same time, combined with the use of magnetic filtration devices, the service life of the lubricating oil is effectively extended and the maintenance cost is reduced.

The modular design also simplifies the component replacement process. For example, when the liner wear reaches the threshold, the main shaft will rise to a specific spacing, at which time the user can accurately plan the maintenance cycle and perform necessary replacement and maintenance work. This design not only improves the maintenance efficiency of the equipment, but also saves users valuable time and cost.

Energy saving, environmental protection and economy

The UH316 cone crusher also performs well in energy saving and environmental protection. The use of Hydrocone technology to optimize the crushing ratio enables the equipment to reduce the number of repeated crushing during the crushing process, thereby reducing the energy consumption per unit output. At the same time, the equipment also supports the crushing and reuse of industrial by-products such as metallurgical slag, improves the utilization rate of resources, and promotes the development of a circular economy.

In on-site crushing mode, the UH316 cone crusher can reduce the need for material transportation, further reducing operating costs. Combined with the use of intelligent feeding control systems, the equipment can reduce idling rates and improve overall work efficiency, thereby creating more economic benefits for users.

Mobile crushing unit UH316 cone crusher Working Principle

The working principle of the UH316 cone crusher deeply integrates the classic dynamic extrusion crushing mechanism of the cone crusher with the essence of modern hydraulic adjustment and intelligent control technology. This efficient and controllable crushing process not only improves the crushing efficiency, but also ensures the precise control of the product particle size.

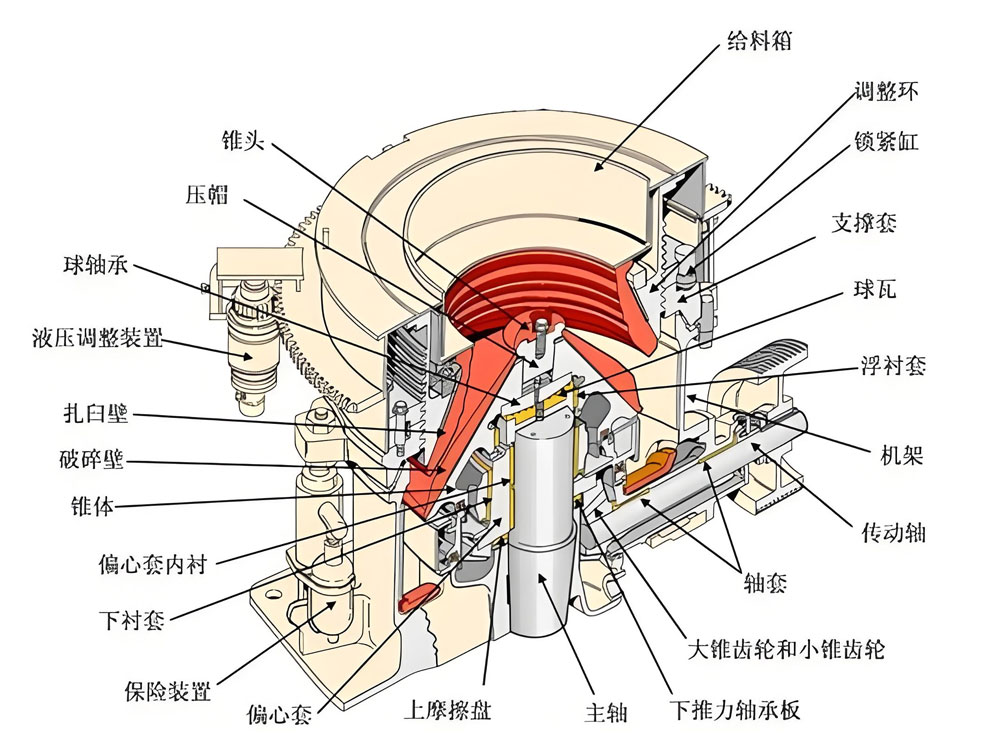

The core of the equipment lies in its main shaft support structure. Driven by the eccentric sleeve, the main shaft drives the moving cone to perform a swinging motion. This movement cooperates with the fixed cone fixed on the frame to form a variable crushing chamber. The material enters from the top feed port of the crusher and is evenly distributed in the annular space between the moving cone and the fixed cone.

With the swinging motion of the moving cone, the material begins to be initially squeezed, bent and sheared in the upper part of the crushing chamber, and this process completes the coarse crushing of the material. With the continuous movement of the moving cone, the material gradually moves downward and enters a narrower crushing chamber area. Here, the material is subjected to a stronger squeezing effect and is gradually crushed to the target particle size.

The hydraulic system plays a vital role in this process. It changes the spacing between the moving cone and the fixed cone, that is, the size of the discharge port, by adjusting the vertical position of the main shaft. This adjustment mechanism enables the equipment to control the discharge particle size in real time as needed. When a finer particle size is required, the hydraulic cylinder pushes the main shaft up to reduce the distance between the moving cone and the fixed cone; conversely, when the processing capacity needs to be increased, the distance is increased.

The drive of the motor is also an indispensable link. The motor drives the horizontal shaft to rotate through the pulley, which in turn drives the eccentric sleeve (eccentric copper sleeve) to produce eccentric movement. This movement forces the moving cone to periodically approach or move away from the fixed cone in a swinging trajectory, forming a continuous extrusion and crushing of the material.

After the crushing is completed, the material that meets the particle size is discharged from the discharge port and then further sorted by the screening equipment (such as vibrating screen) on the lower layer. The oversized material is sent back to the crushing chamber through the return system for secondary crushing, forming a closed loop. This process ensures that all materials can be fully crushed to the required particle size range.

Mobile crushing unit UH316 cone crusher Technical Parameters

| Max. feed size | 185 mm | Weight | 9,500 kg |

| Power | 160 kW | Length | 12.3 m |

| Width | 2.8 m | Height | 5.0 m |