Multifunctional crushing equipment QI341 impact crusher

As an outstanding representative of the combination of modern industrial technology and actual needs, the QI341 impact crusher demonstrates its excellent performance and wide application value in the field of crushing. Its design concept integrates multiple advantages such as high efficiency, flexibility, durability and intelligence, making it an ideal equipment for processing complex materials such as medium-hard ores and construction waste. The efficient crushing capacity of the QI341 impact crusher is due to its carefully designed crushing mechanism. The hammer head made of high manganese steel has extremely high hardness and wear resistance, and can easily cope with high-hardness materials such as granite and basalt, achieving fast and effective crushing. At the same time, the design of the wear-resistant impact plate further improves the crushing efficiency of the equipment, reduces wear and extends its service life.

The intelligent monitoring system has brought the performance of the QI341 impact crusher to a new level. The system can provide real-time feedback on the operating status of the equipment, including key parameters such as motor current, bearing temperature, vibration, etc., to achieve fault warning and remote monitoring. The warning accuracy rate is as high as 99%, ensuring the safe and reliable operation of the equipment. This intelligent management method not only improves production efficiency, but also reduces the risk of accidents. In addition, the maintenance convenience of QI341 impact crusher is also a highlight. The equipment has a simple structure and is easy to disassemble and clean, which greatly reduces the maintenance cost and time. At the same time, the machine body and crushing chamber lining made of high-strength steel have high tensile strength and toughness, which further enhances the durability and stability of the equipment.

Multifunctional crushing equipment QI341 impact crusher Applications

In the mining field, QI341 impact crusher is mainly used for medium and fine crushing of ores. It can effectively crush medium-hardness ores such as limestone, quartz sand, dolomite, etc., and convert them into crushed materials with uniform particle size and regular shape. Its selective crushing function can maintain the cubic shape of the material and reduce the generation of needle-like particles, thereby improving the utilization value and market competitiveness of the ore. In addition, QI341 impact crusher is also widely used in the field of tailings treatment. By recovering the useful components in the tailings, it maximizes the utilization of resources and reduces resource waste and environmental pollution.

In the construction field, QI341 impact crusher also performs well. It can convert construction waste and waste concrete into recycled aggregates, which can be used to produce new building materials such as recycled concrete, recycled bricks, etc., thereby realizing the recycling of resources. At the same time, QI341 impact crusher can also crush building materials such as concrete, stone, bricks, etc. to meet the construction industry's demand for crushed materials. Its efficient crushing capacity and precise particle size control provide high-quality crushing material guarantee for the construction industry.

In the construction of infrastructure such as roads and railways, QI341 impact crusher also plays an important role. It can crush large stones into the required particle size and provide high-quality fillers for roadbed filling. These fillers have the advantages of uniform particle size, regular shape and good compaction, which can improve the stability and bearing capacity of the roadbed. At the same time, the efficient crushing capacity and flexible adjustment function of QI341 impact crusher enable it to adapt to the crushing needs of stones of different specifications and shapes, providing strong support for infrastructure construction.

In the water conservancy and chemical industries, QI341 impact crusher also has a wide range of applications. It can handle various materials with different hardness, such as slag, quartz sand, basalt, etc., providing the required raw materials and fillers for production. Its powerful crushing capacity and wear resistance ensure the stable operation and long service life of the equipment under harsh working conditions.

In the field of environmental protection, QI341 impact crusher also plays an important role. It can crush and screen construction waste and waste, converting them into renewable resources or for other purposes. This not only helps reduce environmental pollution caused by landfill and incineration, but also achieves effective utilization and recycling of resources.

In cement production, QI341 impact crusher also plays an important role. It can crush cement raw materials such as limestone, coal, slag, etc., to meet the requirements of the cement industry for raw material particle size. Its efficient crushing capacity and precise particle size control provide high-quality raw material guarantee for cement production.

QI341 impact crusher can also be used to crush energy industry materials such as coal and calcium carbide. It can handle medium-hard and brittle materials with a side length of less than 100-500mm to meet the production needs of the energy industry. Its powerful crushing capacity and flexible adjustment function enable the equipment to adapt to the requirements of different materials and crushing particle sizes.

Multifunctional crushing equipment QI341 impact crusher Advantages

Significant technical performance advantages

The crusher adopts advanced impact crushing principle, and realizes efficient crushing operation through multiple high-speed impacts between materials and rotors and impact plates. This crushing method not only improves crushing efficiency, but also significantly reduces energy consumption and electricity consumption, saving operating costs for enterprises. In terms of structural design, the equipment is equipped with high-chromium alloy plate hammers, which have excellent impact resistance and wear resistance, ensuring the stability and durability of the plate hammers under long-term use. At the same time, the use of rigid keyless connection technology further enhances the overall stability of the equipment and improves the continuity and reliability of crushing operations.

In terms of crushing effect, the materials crushed by the crusher are mostly cubic particles with extremely low needle-like content. This kind of aggregate with uniform particle shape has excellent compressive strength and is very suitable for the preparation of high-grade concrete. In order to meet the crushing needs of different users, the equipment also further improves the crushing efficiency by optimizing the shape of the crushing chamber and the size of the feed port, so that the equipment can perform well when handling various materials.

Outstanding convenience of operation and maintenance

The crusher also performs well in operation and maintenance. The equipment supports controlling the discharge particle size by adjusting the rotor speed or the gap between the impact plates. This flexible adjustment method enables the equipment to adapt to diversified production needs. It is worth mentioning that the hydraulic system can realize remote and rapid adjustment, which greatly improves the operating efficiency. In terms of maintenance, the hammer adopts a modular design, and the wear is mainly concentrated on the material-facing surface, making replacement more convenient. At the same time, the overall structure is simple and the key components are easy to disassemble, which effectively reduces the downtime and improves the utilization rate of the equipment.

Significant operation economy

From the perspective of operation economy, the crusher also has significant advantages. The equipment consumes less power during operation, and the comprehensive energy consumption is about 50,000 yuan lower than that of similar equipment, which greatly reduces the operating costs of the enterprise. In addition, the equipment has a low failure rate and no significant vibration or shutdown problems, ensuring the continuity and stability of production. At the same time, the crusher can handle materials with a side length of ≤1300mm and a compressive strength of ≤350MPa, which is suitable for the crushing of medium-hard materials (such as limestone, granite, etc.). The single machine has a large processing capacity and a high crushing ratio, which further improves the production efficiency of the enterprise.

Powerful environmental adaptability

In terms of environmental protection, the crusher also performs well. The equipment adopts a sealed structure combined with dust and silencer devices to effectively control dust spillage and noise pollution, and meets modern industrial environmental protection standards. This design not only protects the environment, but also creates a healthier and safer working environment for operators.

Wide application scenarios

The crusher has been widely used in many fields due to its excellent technical performance, convenient operation and maintenance, significant operating economy and strong environmental adaptability. Whether it is mining, construction waste recycling or cement, chemical and other industries, this equipment can play its unique advantages. It is especially suitable for secondary crushing scenarios in conjunction with jaw crushers, taking into account the needs of stone crushing and sand making, and providing enterprises with a more comprehensive and efficient crushing solution.

Multifunctional crushing equipment QI341 impact crusher Work Principle

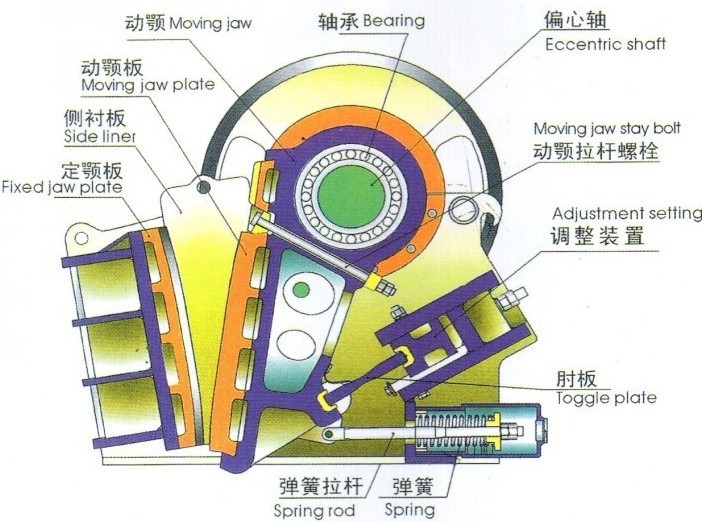

The impact crusher is an efficient and versatile crushing equipment. Its core working principle is mainly based on the impact crushing process of materials. When the material enters the crushing chamber through the feed port, a series of precisely designed crushing actions begin.

First, the material collides with the high-speed rotating rotor. This rotor is driven by an electric motor and rotates at a very high speed. The high-strength plate hammers installed on it exert the first impact force on the material. This impact force is so strong that it is enough to throw the material to the impact plate in the crushing chamber. Under the impact of the plate hammer, the material hits the fixed impact plate at a very high speed, resulting in secondary crushing. This process not only crushes the material, but also gives it enough kinetic energy to prepare for the subsequent crushing action.

The material then rebounds from the impact plate back to the rotor area. Here, they collide again with the subsequent material or plate hammers, forming a cyclic crushing process. This cyclic crushing mechanism ensures that the material is fully crushed in the crushing chamber until it reaches the required particle size. The materials in the crushing chamber frequently collide with each other due to high-speed movement, further reducing the particle size. This collision has a significant shaping effect on the needle-like particles of hard materials (such as granite and limestone), making the final product more uniform and regular.

In order to control the particle size of the discharge, the impact crusher is also designed with the function of adjusting the gap between the impact plate and the rotor. This gap can be adjusted mechanically or hydraulically. The smaller the gap, the more times the crushing is performed, and the finer the particle size of the finished product. This flexible adjustment mechanism enables the impact crusher to adapt to the crushing needs of different particle sizes and provide users with more diverse crushing solutions.

Finally, the materials that meet the particle size requirements are discharged through the bottom discharge port, while the particles that do not meet the standards continue to circulate in the crushing chamber until they meet the requirements. This precise particle size screening and discharge mechanism ensures that the impact crusher can produce high-quality, standard-compliant crushed products.

Multifunctional crushing equipment QI341 impact crusher Technical Parameters

| Feed opening | 992 x 670 mm | Max. feed size | 600 mm |

| length | 14.1 m | width | 2.5 m |

| height | 3.4 m | Weight | 40,276 kg |