NP1620 HSI crusher for aggregate production and mining operations

To fully upgrade your production efficiency, the maximum available power of the NP13 crusher has now been increased to 315 kW, while the maximum available power of the NP15 single-drive version has been increased to 355 kW, and the dual-drive version is up to 630 kW. Regarding the use of NP crusher in artificial sand applications, we provide the following suggestions: NP crusher is known for its excellent particle shape, and the particles it produces are more angular than rounded, which is very ideal. As a processing equipment, the NP crusher shows a high tolerance to the fine powder content in the feed, making it the first choice for closed-circuit operating environments. In addition, the NP crusher can easily cope with various processing needs due to its high reliability and good adaptability to feed fluctuations and sticky materials. With its low wear characteristics and wide application in soft rock and production of aggregates and coarse artificial sand (particle size less than 6mm), HSI technology has become a popular choice in the industrial and asphalt sand fields. It has been proven for many years and is trustworthy.

NP1620 HSI crusher Applications

Mine and Quarry Application: The NP1620 HSI crusher is specially designed for stone crushing operations in mines and quarries. It can significantly improve production efficiency and ensure efficient operation.

Construction waste processing field: This equipment also plays an important role in the recycling and reuse of construction waste. Through efficient crushing processing, materials originally regarded as waste are converted into valuable renewable resources, helping environmental protection and sustainable development. .

Road and railway construction projects: During the construction process of roads and railways, the NP1620 HSI crusher can be used to crush stones and produce concrete and asphalt aggregates that meet standards, providing a solid material foundation for construction projects.

Metallurgy and Chemical Industry: In addition, this equipment also plays a key role in the metallurgy and chemical industry, used to crush raw materials, provide necessary, processed materials for the production process, and ensure the smooth operation of the production line.

NP1620 HSI crusher Advantages

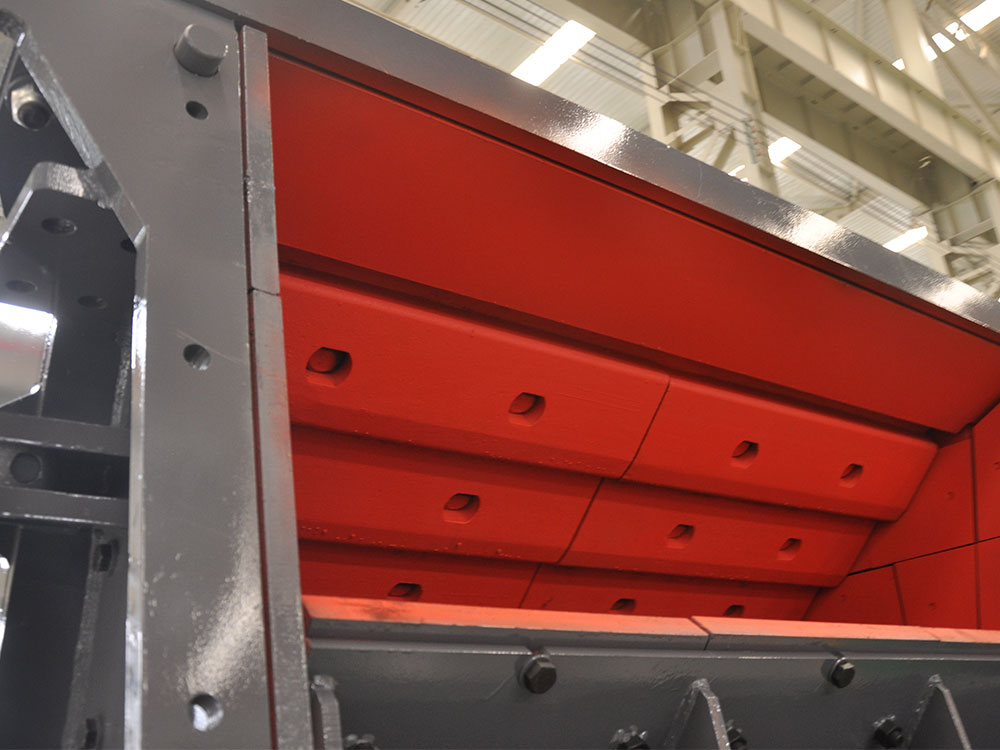

The cornerstone of high performance lies in the ingenious combination of heavy-duty rotors, wear-resistant materials and excellent crushing cavity design. This combination has demonstrated unprecedented revolutionary effects in increasing production capacity, optimizing product quality and reducing operating and wear costs. The unique blow bar connection system significantly reduces the risk of breakage by achieving precise alignment of the back beam contact surfaces and pushes the boundaries of innovation in cast iron applications in blow bars. At rated speed, the high-inertia heavy-duty rotor not only improves crushing efficiency, but also ensures process stability, thereby reducing energy consumption and improving long-term operating efficiency.

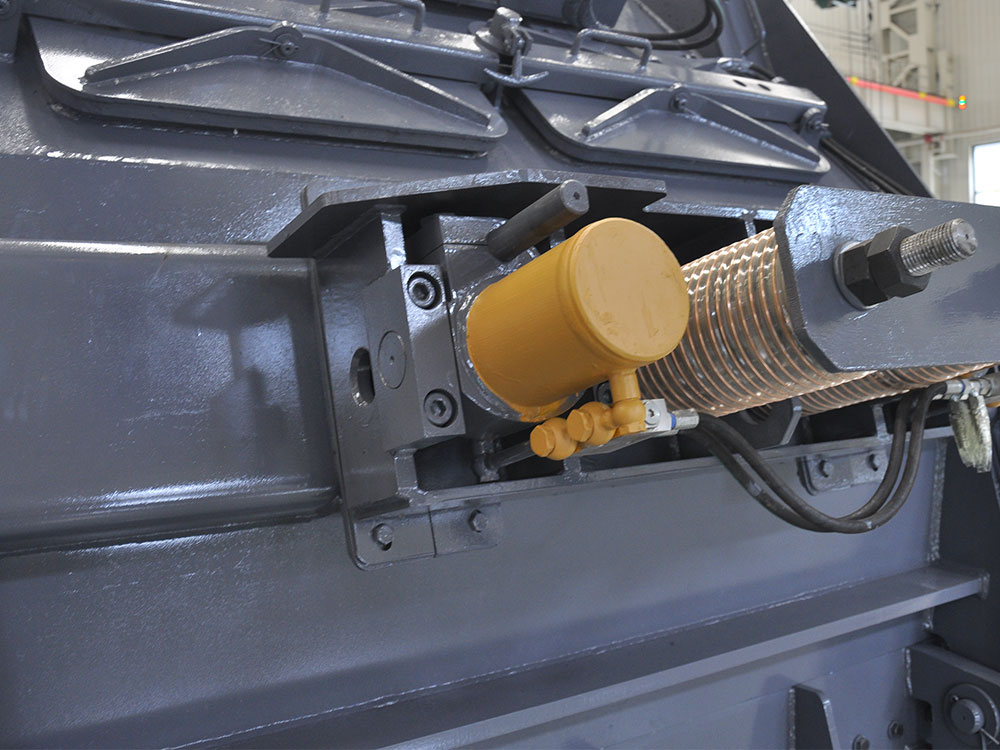

Customized crusher configurations are available upon request. Full hydraulic adjustment, a tertiary crusher plate and a variety of active wear parts options in steel and cast iron allow you to customize the crusher to your needs. At the same time, the integration of automation systems makes crusher operation more intelligent and provides comprehensive performance monitoring.

With its rich crushing experience and close collaboration with customers and research institutions, we continue to promote technological innovation and enhance the reliability of our crushers. The combination of high capacity and efficient reduction ratio creates a high-performance crushing equipment. Where possible, avoiding the third-level crushing stage can significantly reduce capital expenditures and energy consumption. Durable wear parts and mechanical components further reduce maintenance costs. The high reliability of the machinery, the simplification of the process, the convenience of operation, and the safety and simplicity of maintenance jointly enhance the factory's global competitiveness and profitability.

NP1620 HSI crusher Working Principle

The working principle of the impact crusher is to use the impact energy to break the material. When the material enters the plate hammer area, it will be immediately crushed by the high-speed impact of the plate hammer, and then thrown to the impact device on the top of the rotor to be crushed again. After that, the material will rebound from the impact liner to the plate hammer area and continue to experience the crushing process. This process will be repeated until the material is crushed to the required particle size and then discharged from the bottom of the machine. In addition, by adjusting the gap between the impact frame and the rotor frame, the particle size and shape of the crushed material can be flexibly controlled.

NP1620 HSI crusher Technical Parameters

| Total weight | 40 500 kg (89 290 lbs) | Shaft line weight | 15 980 kg (35 236 lbs) |

| Rotor diameter | 1 600 mm (63") | Rotor width | 2 000 mm (78 3/4") |

| Nominal installed power | 400 kW (2x200 kW) / 500 HP (2x250 HP) | Maximum installed power | 630 kW (2x315 kW) / 840 HP (2x420 HP) |

| Feed opening | 2 040 x 1 430 mm (80.3" x 56.3") | Maximum feed size | 1 300 mm (51") |