NW330GP for any crushing need

NW330GP cone crusher, as the star product of NW series wheeled cone crushing station, is equipped with efficient GP330 cone crusher, specially designed to meet the high requirements of medium crushing operations. This crusher uses electricity as its driving source and has a crushing power of up to 400KW, demonstrating its extraordinary crushing strength.

The NW330GP cone crusher is favored in many industrial fields due to its excellent performance and stable operating characteristics. Its advanced crushing cavity design, combined with the laminated crushing principle, makes the crushing process more efficient, the crushing ratio is significantly improved, and the finished product particle size is more uniform. The equipment has a compact structure and reasonable design, which ensures the stability and reliability of operation, while reducing the failure rate and bringing lower maintenance costs to users.

In addition, the NW330GP cone crusher also has excellent mobile performance. Its wheeled chassis design allows the equipment to be quickly moved and set up between production sites, making it highly adaptable and flexible. At the same time, the equipment is also equipped with an advanced intelligent control system that supports multiple functions such as remote monitoring and automatic adjustment, making operation more convenient and efficient.

NW330GP for any crushing need Applications

In the mining field, the NW330GP cone crusher can easily cope with the crushing needs of various metal ores, such as iron ore, copper ore, gold ore, etc. Its powerful crushing capacity and adaptability to hard rock significantly improve the recycling rate of ore and bring considerable economic benefits to mining companies.

In the construction industry, the NW330GP cone crusher also shows extraordinary strength. It can convert construction waste, waste concrete and other materials into recycled aggregates for the production of new building materials. This recycling method not only helps environmental protection, but also improves resource utilization and contributes to the sustainable development of the construction industry.

In addition, in the chemical industry, the NW330GP cone crusher also plays an important role. It can crush various hardness and hard and brittle chemical raw materials to ensure the stability of the production process and the quality of the products. Its efficient crushing performance and stable operating status provide a strong guarantee for the production of chemical companies.

NW330GP for any crushing need Advantages

Modular design

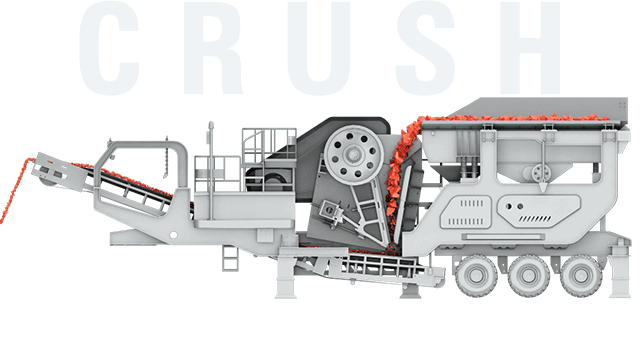

Adopting a highly integrated modular design concept, the whole machine has a compact structure and a reasonable spatial layout. It can be divided into nine modules: crawler walking module, power module, feeding module, crushing module, hydraulic module, electrical control module, belt conveyor module, screening module, and platform cover module. The technology of each subdivided module is more professional, and the matching between modules is more tacit, achieving uniform feeding, continuous crushing, full screening and classified transportation.

Flexibility

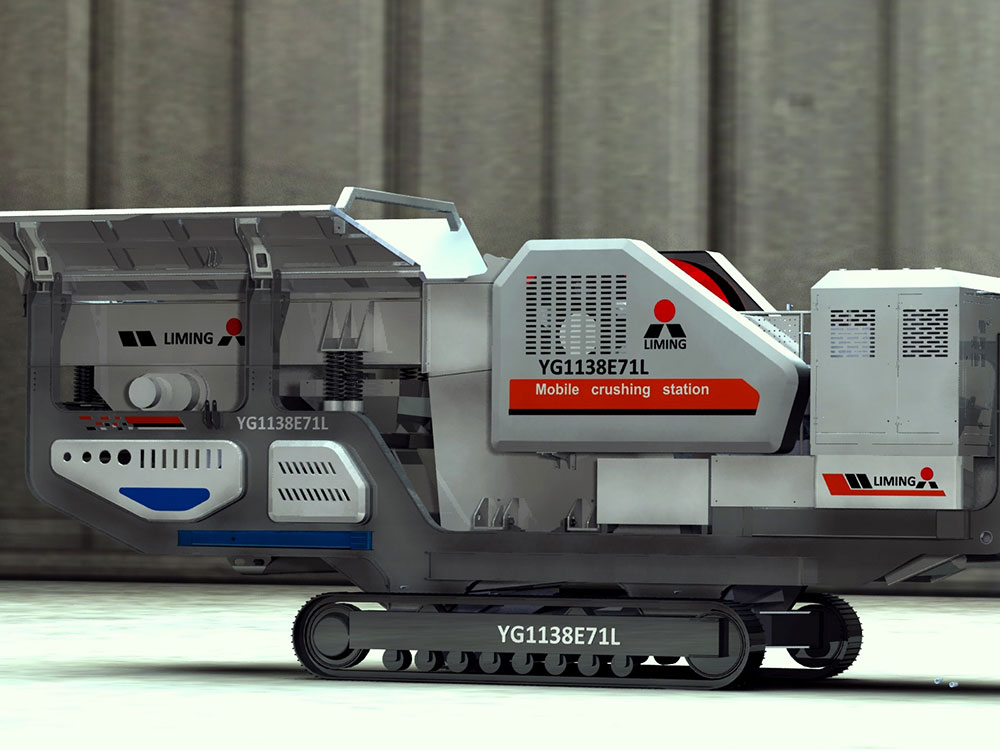

The whole machine is designed in accordance with international road transportation standards to meet the requirements of integral transportation without disassembly, saving transportation costs for users. The crawler walking mechanism made of special materials can travel flexibly in rugged and harsh terrain, and can quickly enter the construction site to save time. It can adapt to harsh working environments and provide more flexible space for the reasonable arrangement of crushing and screening processes to achieve a reasonable layout.

Intelligent control

Equipped with a variety of sensitive and high-precision sensors, it can timely collect various working data during equipment operation, monitor the operating status of the equipment in real time, and automatically handle various situations that occur during work in a timely manner, effectively protecting the normal operation of the whole machine. The operation control system has a friendly interface, simple operation and convenient maintenance.

Effectively reduce costs

The machine can crush and classify materials on the spot. The specially designed return material circulation crushing mechanism can continuously crush the first crushed materials after the initial screening, which significantly reduces the intermediate links and reduces the transportation costs of materials. At the same time, the equipment can also output three finished materials at one time according to the user's requirements for finished materials, meeting the user's various requirements for mobile crushing and screening. The material processing process is more reasonable and effectively reduces costs.

NW330GP for any crushing need Working Principle

The working principle of NW330GP cone crusher is similar to that of most cone crushers. When the crusher is working, the motor drives the eccentric sleeve to rotate through the transmission device. The rotation of the eccentric sleeve causes the movable cone connected to it to produce a pendulum motion, that is, the movable cone rotates and swings around a fixed point. This movement makes the surface of the movable cone sometimes approach the inner surface of the fixed cone and sometimes leave it. When the movable cone approaches the fixed cone, the material between the two cones will be strongly squeezed, rubbed and bent, thereby achieving crushing. After multiple crushing, the material reaches the required particle size and is discharged from the crusher's discharge port. It is precisely because of its scientific and efficient working principle that NW330GP cone crusher has demonstrated excellent performance and wide application value in many industrial fields.

NW330GP for any crushing need Technical Parameters

| Transport length | 11,592 mm (38' 0) | Transport width | 2,530 mm (8' 4") |

| Transport height | 3,990 mm (13' 1") | Transport weight | 35,718 kg (78,745 lbs.) |

| Bogie weight | 19,947 kg (43,976 lbs.) | King pin weight | 15,771 kg (34,769 lbs.) |

| Feed opening | 215 mm (8 15/32") | Motor power | 315 kW (425 hp) |