Optimised crushing chamber design for CG810i gyratory crusher

The CG810i gyratory crusher has an ingenious internal structure, including beams, upper, middle and lower frame, dynamic cone, eccentric sleeve, transmission and hydraulic cylinder. All components are well-designed and work together to ensure the smooth operation of the crusher. The spindle position control system is equipped with displacement sensors as standard, displaying the spindle position in real time, and the hydraulic cylinder automatically adjusts the discharge opening by making up the pressure, precisely compensating for the wear of the lining plate, thus stabilising the particle size and increasing the productivity. The machine adopts the design of large inclined angle crushing chamber and long crushing surface, with excellent crushing capacity. With the optimised stroke and speed, it can easily cope with all kinds of coarse crushing operations. The large crushing chamber facilitates the crushing of stone materials, improves efficiency and extends the life of the liner. Heavy-duty spindle design with integral forging prevents cone loosening and reduces downtime. The upper journal is enlarged and polished with large radius arc, which enhances the strength and durability of the main shaft and adapts to the harsh crushing conditions. The wear of crushing chamber is evenly distributed, reducing the frequency of liner replacement and lowering the production cost.CG810i gyratory crusher has outstanding performance in handling large materials, which is highly efficient, stable and durable. These features make it have a broad application prospect in mining, construction and other industries.

Optimised crushing chamber design for CG810i gyratory crusher Applications

Mining industry is one of the most important application areas for CG810i gyratory crushers. During the mining process, large size ores often need to be crushed for subsequent transport and processing. with its powerful crushing capacity and high efficiency, CG810i gyratory crusher can easily cope with various hardness of ores, such as granite, iron ore, limestone, etc. The internal structure is reasonable and the design of large inclined chamber and longer crushing surface makes the crushing process smoother. Its internal structure is reasonable, with a large inclined crushing chamber and longer crushing surface design, which makes the crushing process smoother and the crushing efficiency significantly improved. Meanwhile, the heavy-duty spindle design and integral forged spindle ensure the stability and durability of the equipment, reducing downtime and maintenance costs and providing a strong guarantee for the continuous production of mining enterprises.

Construction industry is another area where CG810i gyratory crusher is widely used. In building construction, sand and gravel aggregate is an indispensable raw material for the preparation of concrete, mortar and other building materials.CG810i gyratory crusher is able to crush rocks into sand and gravel aggregate that meets the requirements, which provides a solid material foundation for the rapid development of the construction industry. Its high efficient crushing capacity and stable performance ensure the output and quality of sand and gravel aggregate, which meets the high demand for sand and gravel aggregate in the construction industry. In addition, CG810i gyratory crusher also has good environmental performance, reducing dust and noise pollution in the crushing process, which meets the green construction requirements of modern construction industry.

In the metallurgical industry, CG810i gyratory crusher also plays an important role. The metallurgical process needs to deal with a large number of ores and slags, which often need to be crushed for subsequent smelting and processing. CG810i gyratory crusher can easily cope with the crushing needs of these materials, and its strong crushing capacity and stable performance ensure the smooth progress of the smelting process. Meanwhile, the CG810i gyratory crusher also has a high degree of automation, and can achieve good linkage and co-ordination with other metallurgical equipment, which improves the efficiency of the whole metallurgical production line.

In addition, CG810i gyratory crusher has a wide range of applications in the chemical industry. In the process of chemical production, many raw materials need to be crushed for subsequent chemical reaction and processing. CG810i gyratory crusher can adapt to the crushing needs of different raw materials, and its flexible adjusting mechanism and high efficient crushing capacity ensure the smooth progress of chemical production. At the same time, CG810i gyratory crusher also has good corrosion resistance, can cope with the corrosive substances in the chemical raw materials, to extend the service life of the equipment.

Optimised crushing chamber design for CG810i gyratory crusher Advantages

Stability and Reliability

The CG810i gyratory crusher adopts advanced design concepts to ensure the stable operation of the equipment under severe working conditions. Its robustly designed one-piece spindle and reinforced frame body, built for harsh working environments, are able to withstand tremendous impact and pressure, effectively extending the equipment's service life. In addition, the wear-resistant life of the one-piece spherical upper boom bearings is at least five times longer, thanks to its well-designed structure and the use of high-quality wear-resistant materials, which ensures the stability and reliability of the equipment over long periods of operation.

Excellent performance

The CG810i gyratory crusher also excels in terms of performance. With its high crushing ratio and high capacity, the machine can easily handle ores and rocks of various hardnesses and sizes. The material in the crushing chamber is subjected to multiple extrusion and splitting, and is finally crushed into small pieces with uniform product size, which meets the production needs of different industries. Meanwhile, the CG810i gyratory crusher also features low energy consumption and high efficiency, which can ensure the crushing effect and at the same time, effectively reduce the production cost and improve the economic benefits.

Easy Maintenance

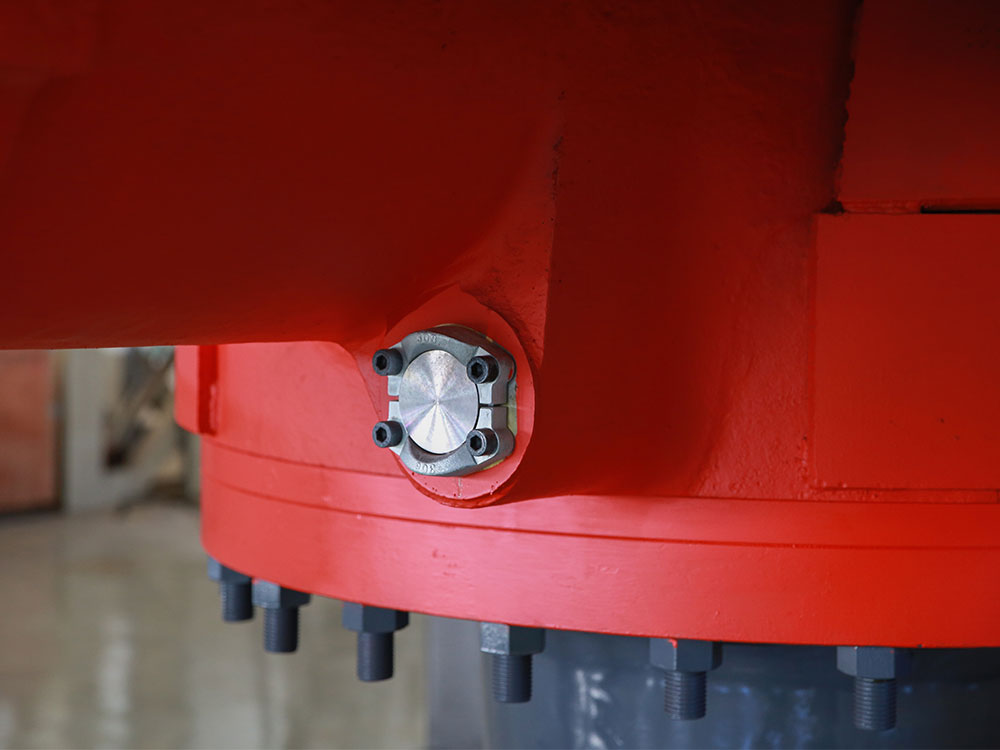

In terms of maintenance, CG810i gyratory crusher also shows its unique advantages. The machine is designed for easy maintenance, which makes routine maintenance and repair work easier and faster. For example, the tightened self-tightening mill wall prevents the liner from loosening, reducing downtime due to loose liners. In addition, the Tank Instrumentation Monitoring System (TIMS) provides real-time monitoring of the crusher's lubrication system, ensuring that the oil is at the proper flow and temperature conditions and triggering alarms when necessary to protect the equipment. These intelligent and automated maintenance tools greatly reduce the difficulty and cost of equipment maintenance and improve equipment reliability and service life.

Intelligent

The CG810i gyratory crusher also offers the advantage of intelligence. Through an integrated intelligent system, the machine is able to automatically adjust crusher settings to compensate for crushing chamber wear and ensure consistent product size. The automation system optimises the performance of the crusher without overloading it, allowing you to use the crusher to its full potential. Intelligent features not only improve plant productivity and product quality, but also provide users with more convenient and efficient management tools.

Efficient Operation

From an economic point of view, the CG810i gyratory crusher also offers significant advantages. Although the initial investment of the equipment may be high, its low operating costs, long maintenance intervals and long service life make the equipment able to bring higher economic benefits to users in the long term. In addition, the efficient operation and low failure rate of the equipment also greatly reduces the maintenance workload, ensures the continuity of the production line, and further improves the production efficiency and economic benefits of the enterprise.

Optimised crushing chamber design for CG810i gyratory crusher Working Principle

The working principle of the CG810i gyratory crusher is based on its unique crushing chamber design and gyratory motion mechanism. Inside the crusher, an annular space, i.e. the crushing chamber, is formed between the movable cone and the fixed cone. The material is fed into the crushing chamber from the upper part, and with the operation of the crusher, the movable cone makes a rotary oscillation movement inside the fixed cone. This movement is driven by an electric motor, which is converted into a rotary movement of the eccentric bushing through a transmission device, and then drives the movable cone to make an eccentric rotary movement around the centre line of the machine.

When the movable cone is close to the fixed cone, the material between the two cones is subjected to strong extrusion and splitting, thus realising crushing. As the movable cone continues to rotate, the crushed material is pushed to the bottom of the crushing chamber and discharged through the discharge port. During this process, the material is crushed continuously, ensuring the high efficiency and stable performance of the crusher.

The crushing action of the CG810i Gyratory Crusher not only relies on the crushing and splitting action between the movable and stationary cones, but also further refines the material through multiple impacts and shearing in the crushing chamber. The special design of the crushing chamber allows the material to be subjected to multiple impacts and shearing during the crushing process, thus improving crushing efficiency and product quality.

Optimised crushing chamber design for CG810i gyratory crusher Technical Parameters

| Feed opening | 1,067.0 mm | power | 315 kw |

| Weight | 128 tonne | Horizontal Shaft | 500 rpm |

| Automation | Standard | Open side setting | 115.0 - 190.0 mm |