Preferred Equipment for Mining C96 Jaw Crusher

C96 Jaw Crusher, a crushing equipment combining advanced design and high quality materials. The unique design of the crushing chamber and the optimised movement trajectory enable the material to be squeezed and split in all directions in the chamber, which significantly improves the crushing efficiency. Meanwhile, the jaw plate is made of high wear-resistant material, which is durable and effectively reduces the replacement frequency and maintenance cost.

The outlet size of the crushing chamber of C96 jaw crusher can be adjusted flexibly according to the user's needs, which can easily achieve the crushing needs of different particle size products. The C96 also excels in terms of manufacturing process and components. The advanced manufacturing process and selected quality components ensure stable operation and reduce the possibility of failure.

In addition, the C96 is equipped with convenient maintenance features and special tools, making maintenance work easy and quick. In particular, its standard jaw liner rear guard, replaceable wedge and composite shield design greatly simplifies the disassembly and installation work, providing users with great convenience.

Preferred Equipment for Mining C96 Jaw Crusher Applications

In the construction industry, C96 jaw crusher can be used to crush construction waste such as concrete, masonry, etc., and turn them into reusable aggregates. Meanwhile, it can also be used to prepare construction aggregates, such as limestone, gypsum and so on, providing high quality crushing products for the construction industry.

In road construction, C96 jaw crusher can be used for crushing and recycling road waste materials, such as asphalt, cement blocks and so on. After crushing, these materials can be used as materials for road base layer or surface layer, realising the reuse of resources.

In metallurgical industry, C96 Jaw Crusher is commonly used to crush metallurgical raw materials, such as iron ore, manganese ore and so on. Its fine crushing effect and adjustable crushing size help to meet the strict requirements of metallurgical industry on raw material size.

In the mining industry, C96 Jaw Crusher is commonly used for mining and primary crushing of various ores and rocks, such as iron ore, copper ore, manganese ore and so on. Its powerful crushing capacity and wear-resistant and durable features enable the equipment to run stably for a long time, meeting the mining industry's demand for efficient and reliable crushing equipment.

In the recycling industry, C96 jaw crusher can be used to crush and recycle waste metals, plastics and other recyclable wastes. After crushing, these wastes can be classified and reused more conveniently, which helps to realise the recycling of resources.

Preferred Equipment for Mining C96 Jaw Crusher Advantages

Wide Applicability

C96 jaw crusher is widely used in many fields such as mining, building materials, metallurgy and so on. Its powerful crushing capacity and wide applicability enable the machine to meet the needs of different industries for crushing equipment. The C96 Jaw Crusher can be used in the mining of ores, the preparation of building aggregates and the recycling of waste materials.

Stable and reliable operation

The equipment adopts advanced manufacturing technology and high-quality components to ensure stable and reliable operation. This reduces the failure rate and downtime, and improves the reliability and service life of the equipment. At the same time, stable operation also ensures the quality and consistency of crushed products.

Flexible and easy adjustment

The C96 Jaw Crusher usually has an adjustable outlet size of the crushing chamber, which allows the user to adjust the size of the crushed product according to the needs. This flexibility allows the machine to be adapted to different production requirements, providing users with more diversified crushing solutions.

Wear-resistant and durable

The jaw plate and other key parts of the machine are made of high wear-resistant materials, which have a long service life. This means that users can reduce the frequency of replacing jaws and other parts, thus reducing maintenance costs and downtime. At the same time, the wear-resistant and durable nature of the C96 Jaw Crusher also enables it to maintain stable operation under harsh working conditions.

High Crushing Capacity

The C96 Jaw Crusher adopts an advanced crushing chamber design and optimised movement trajectory, which makes the material fully squeezed and split in the crushing chamber, thus achieving high crushing efficiency. This efficient crushing capacity not only improves the production efficiency, but also reduces the energy consumption and saves the operating cost for the users.

Preferred Equipment for Mining C96 Jaw Crusher Working Principle

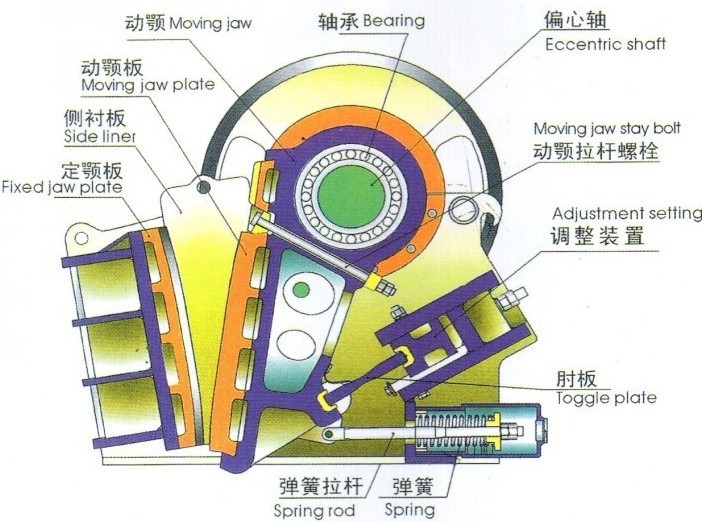

C96 Jaw Crusher, its core components are the fixed jaw plate and the movable jaw plate, the movable jaw plate is linked with the drive device through the precision eccentric shaft. When the drive unit starts with a roar, the movable jaw plate starts to reciprocate rhythmically around the eccentric shaft.

In the crushing operation, the movable jaw plate gradually approaches the fixed jaw plate, and the gap between the two is constantly narrowing, forming a strong extrusion effect on the material. Under this strong squeezing effect, the material undergoes a series of complex physical processes such as crushing, splitting, bending, etc., and is finally crushed into the required particle size.

Once the movable jaw plate completes a crushing stroke, it will move backwards with the driving force of eccentric shaft to make room for the discharge of crushed materials. At this time, the material is smoothly discharged from the outlet at the lower part of the crushing chamber under the effect of gravity, and the whole crushing process is finished.

In addition, the C96 Jaw Crusher also has an extremely practical feature, that is, the adjustability of the outlet size of the crushing chamber. By simply adjusting the outlet size, users can precisely control the particle size of the crushed material to meet the strict requirements of different industries on the particle size of raw materials.

Preferred Equipment for Mining C96 Jaw Crusher Technical Parameters

| speed | 330 rpm | Power | 90 kW |

| Weight | 10 150 kg | width | 930 mm |

| depth | 580 mm | closed side | 60 mm-175mm |