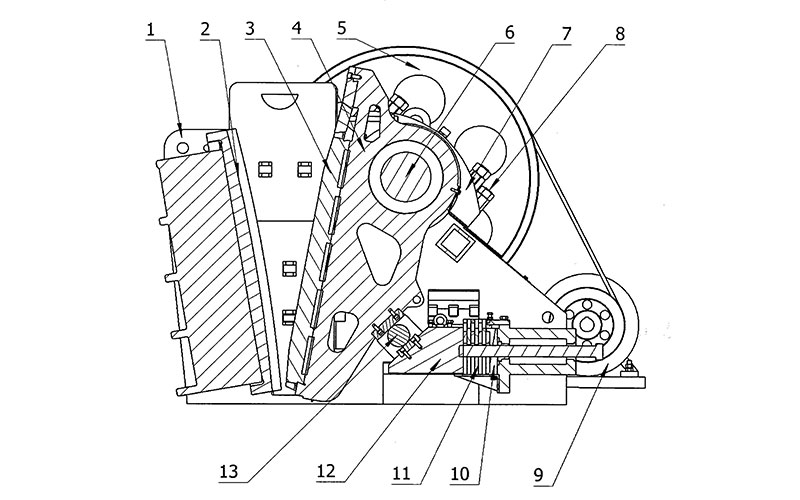

Primary crusher with wide cavity profile C3054 jaw crusher

C3054 jaw crusher consists of two jaw plates, a movable jaw and a static jaw, which form a crushing chamber. It simulates the movement of the two jaws of animals and completes material crushing through bending and extrusion. This equipment is mainly used for coarse and medium crushing of various ores and rocks, and is widely used in mining, building materials, roads, railways and other industries. The compressive strength of the crushed material generally does not exceed a certain value, such as 320Mpa or 80MPa, and when the water content of the material is too high, it may affect the unobstructed feeding of the material. C3054 jaw crusher has the characteristics of large crushing ratio, uniform material particle size, simple adjustment, and convenient material connection. At the same time, it has a reasonable design, convenient maintenance, and simple operation.

C3054 Jaw Crusher Applications

In the field of mining, this equipment is the first choice for coarse crushing of raw stones, laying the foundation for subsequent fine crushing and grinding processes. It is an indispensable key link in the preparation of sand and gravel aggregates. In the building materials industry, it crushes basalt and other raw materials to prepare aggregates required for concrete, asphalt mixture and roadbed construction. In terms of highway and railway construction, it provides high-quality stone materials that meet the strict requirements for railway ballast and highway roadbed materials. In water conservancy projects, crushed stone is widely used in the reinforcement and construction of dams, embankments and other projects. In addition, in the field of construction waste treatment, it shows significant advantages in processing concrete and bricks, and efficiently completes coarse crushing operations. At the same time, this equipment is also suitable for concrete products, chemical industry and other industries.

C3054 Jaw Crusher Advantages

The design of this crushing equipment is extremely simple, making it easy to repair and maintain. Its clear structure allows maintenance personnel to quickly locate and solve problems without complicated operations or special tools. This design not only reduces downtime but also reduces repair costs and allows users to more easily manage the equipment.

High crushing ratio and production efficiency are another highlight of this equipment. The equipment has a large crushing ratio and can quickly crush various materials, significantly improving production efficiency. This means users can complete more work tasks in less time, thus saving time and labor costs.

Low energy consumption and cost savings are also important features of this device. The equipment consumes very little energy during operation, and the wearing parts are made of wear-resistant materials, which has a long service life, further reducing maintenance and operating costs. This energy-saving design not only conforms to the green production concept of modern industry, but also brings real economic benefits to users.

The operational stability of the device and its wide range of applications are equally commendable. Using a hydraulic adjustment device, the equipment remains stable during operation and can cope with various complex working conditions. In addition, it is also suitable for crushing a variety of materials, including materials with higher hardness, meeting the needs of users in different fields.

The quality of crushing effect is one of the important indicators to measure the performance of crushing equipment. This equipment has a large crushing chamber capacity and a suitable crushing angle, which can achieve more complete crushing and make the material shape more uniform. This not only improves product quality, but also reduces the difficulty and cost of subsequent processing.

In terms of safety performance, this device also performs well. The equipment is designed with full consideration of operational safety and strict operating procedures have been formulated. Users can strictly follow the procedures during use to ensure the safety of people and equipment.

C3054 Jaw Crusher Working Principle

The C3054 jaw crusher is mainly composed of two jaw plates, the movable jaw and the static jaw, which form a crushing chamber. The material is crushed by simulating the movement of animal jaws. This design not only makes the crushing process more natural and smooth, but also greatly improves the crushing efficiency and crushing quality. The movable jaw and the static jaw are the core components of the C3054 jaw crusher. The movable jaw is connected to the motor through a transmission mechanism. When the motor is started, the movable jaw will reciprocate under the drive of the transmission mechanism. This reciprocating motion forms an extrusion effect with the static jaw, so that the material entering the crushing chamber is crushed after being strongly squeezed. Since the motion trajectory of the movable jaw simulates the curve of the animal jaw movement, this crushing method is called curved extrusion crushing. The curved extrusion crushing method has many advantages. First, it can effectively crush the material with uniform crushing particle size and can meet the crushing particle size requirements of different industries. Secondly, the curved extrusion crushing method can reduce the energy consumption in the crushing process and improve the crushing efficiency. In addition, due to the extrusion effect between the movable jaw and the static jaw, the material is not prone to excessive wear during the crushing process, thereby extending the service life of the equipment. The crushing chamber of C3054 jaw crusher is reasonably designed, which allows materials to enter and discharge smoothly. At the same time, wear-resistant materials are used inside the crushing chamber to further improve the durability of the equipment. In addition, the equipment is equipped with an advanced control system, which can achieve precise control of the crushing process, thereby ensuring the stability of crushing quality and crushing efficiency.

C3054 Jaw Crusher Technical Parameters

| Feed opening | 1380 x 760 mm (30” x 54”) | Installed power | 160 kW (200 HP) |

| Speed | 260 rpm | Max. capacity, scalped feed | 670 mtph / 740 stph |

| Max. capacity, non-scalped feed | 1030 mtph / 1125 stph | Weight (basic unit) | 26 500 kg / 58 420 lbs |