Sell CG850i stationary gyratory crusher high efficiency coarse crushing

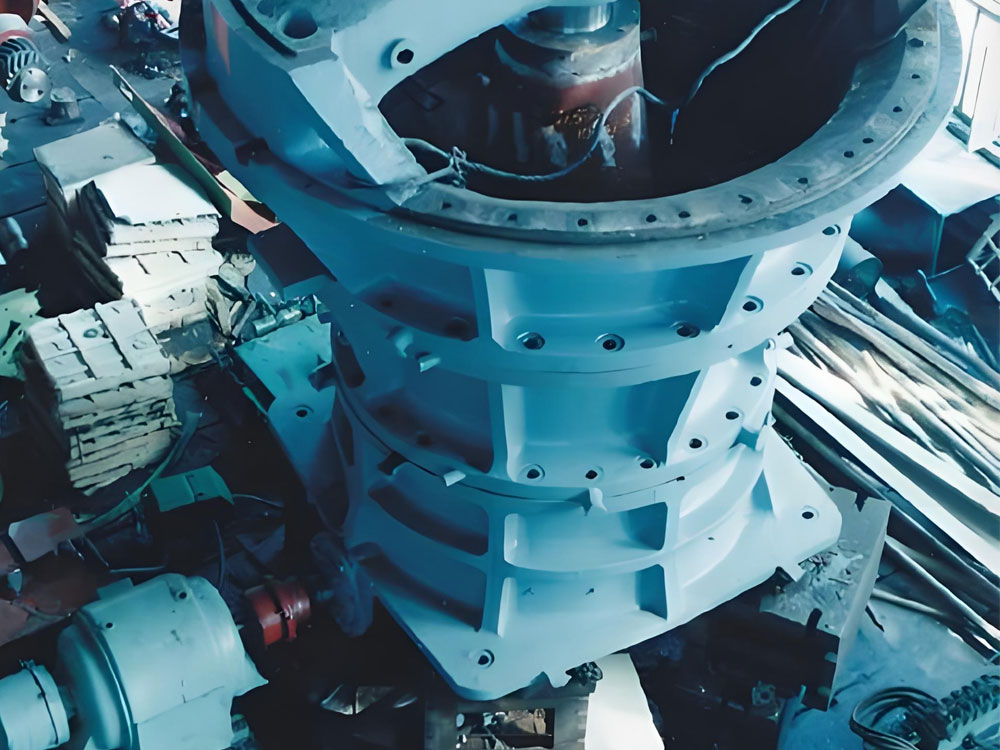

As a powerful crushing equipment, CG850i plays a vital role in the modern industrial field, especially in large-scale crushing production lines such as metal mines, sand and gravel aggregates, etc., it shows its incomparable advantages. This equipment is especially suitable for coarse crushing of hard rock in open pit mines, and its powerful crushing capacity and adaptability make all kinds of complex crushing tasks easy and comfortable.The CG850i's high efficiency, stability and intelligence are its most remarkable features. In terms of high efficiency, the machine adopts advanced crushing technology and design concepts, capable of completing a large number of crushing tasks in a short period of time, which greatly improves production efficiency. In terms of stability, the CG850i has undergone rigorous testing and verification, and can maintain stable operation under a variety of harsh working environments, ensuring the continuity and stability of production. As for intelligence, the equipment is equipped with advanced control system and monitoring device, which can monitor the running status and working parameters of the equipment in real time, and automatically adjust and optimise them according to the actual situation, thus realising more intelligent production and management. When the machine is in operation, the main shaft with crushing cone will make eccentric rotary movement in the eccentric hole of the shaft sleeve. This movement makes the material in the crushing chamber subject to a variety of forces such as extrusion, splitting and bending, so as to achieve continuous and efficient crushing. At the same time, the discharge opening is designed to be very flexible and can be adjusted mechanically or hydraulically to suit production tasks with different particle size requirements. This design not only increases the flexibility of the machine, but also greatly expands its range of applications.

The CG850i also has excellent overload protection. When the machine encounters an overload situation during the working process, the hydraulic system will automatically adjust the size of the discharge opening to discharge the non-crushed materials, thus avoiding damage and failure of the machine. This intelligent overload protection mechanism not only improves the safety and reliability of the equipment, but also reduces the user's maintenance cost and risk of use.The CG850i also excels in terms of wear resistance and crushing ratio. Its one-piece spherical upper boom bearing design increases the wear life by 5 times, which means that users can go longer without replacing the bearings, thus reducing maintenance costs and usage costs. Meanwhile, the high crushing ratio design ensures that 90% of the feed opening can operate normally, and the 950kW motor power is suitable for the machine, which makes the machine excel in handling materials of various hardnesses and particle sizes. The CG850i is also very easy to install and use. The machine needs to be installed on a horizontal concrete foundation for fixing to ensure its stability and safety. A special lubrication system is also required to extend bearing life and improve operating efficiency. These installation and use requirements are simple and straightforward, allowing users to get started and quickly learn how to operate and maintain the machine.

Sell CG850i stationary gyratory crusher high efficiency coarse crushing Applications

In the mining industry, the CG850i crusher has become the preferred equipment for coarse crushing of iron ore, copper ore and other hard minerals with its excellent performance. With a capacity of up to 3,800-8,250 tonnes per hour, it is perfectly adapted to the demands of large-scale ore mining. This means that even with large quantities of hard ore, the CG850i is able to complete crushing tasks quickly and efficiently, ensuring continuous and efficient mine production. The machine's ability to handle large boulders with feed sizes ranging from 1,550 to 4,140 mm makes it easily adaptable to the requirements of the primary crushing process in mines. After entering the crushing chamber, the CG850i's powerful crushing process quickly breaks down the large ore into small particles suitable for subsequent processing, laying a solid foundation for the efficient operation of subsequent processes.

In the metallurgical industry, the CG850i crusher also plays an important role. It is capable of crushing ferrosilicon, iron ore and other metallurgical raw materials, providing uniform particle size materials for the smelting process. This is important for improving smelting efficiency, reducing energy consumption and improving product quality. At the same time, metallurgical production environment is usually harsh, high temperature and high load is the norm. However, the CG850i is able to maintain stable operation in such extreme environments, supported by its wear-resistant materials and efficient lubrication system. This not only ensures production continuity, but also effectively extends the service life of the equipment and reduces maintenance costs for users.

In the building materials industry, the CG850i crusher is widely used in the production of sand and gravel aggregates. It provides high-quality raw materials for concrete mixing stations and dry mortar, ensuring the high quality and stability of building materials. In addition, the machine can also process limestone, granite and other building materials to meet the high standard demand for construction sand and gravel. These raw materials, after being crushed and processed by CG850i, are of uniform particle size and high quality, providing a strong guarantee for the quality of construction projects.

In the field of infrastructure construction, CG850i crusher also plays an irreplaceable role. It participates in road construction, house demolition and other projects, and realises the recycling of resources by crushing construction waste (such as concrete blocks). This not only helps to reduce the pollution of construction waste to the environment, but also transforms the waste into valuable resources, contributing to the sustainable development of infrastructure construction.

In the chemical industry, the CG850i crusher is capable of crushing quartz, graphite and other chemical raw materials, providing the necessary raw materials for the chemical production process. These raw materials have a more uniform particle size after crushing, which is beneficial to the subsequent chemical reaction and processing. Meanwhile, the CG850i also plays an important role in the power industry. It is able to process limestone and other materials in the desulphurisation process of power plants, assisting in environmental protection and emission reduction. By crushing limestone and other desulphurising agents, CG850i provides a stable and efficient supply of raw materials for the desulphurisation process in power plants, which helps to reduce the emission of sulphur dioxide and other harmful gases and protects the atmospheric environment.

Sell CG850i stationary gyratory crusher high efficiency coarse crushing Advantages

High efficiency continuous crushing and processing capacity

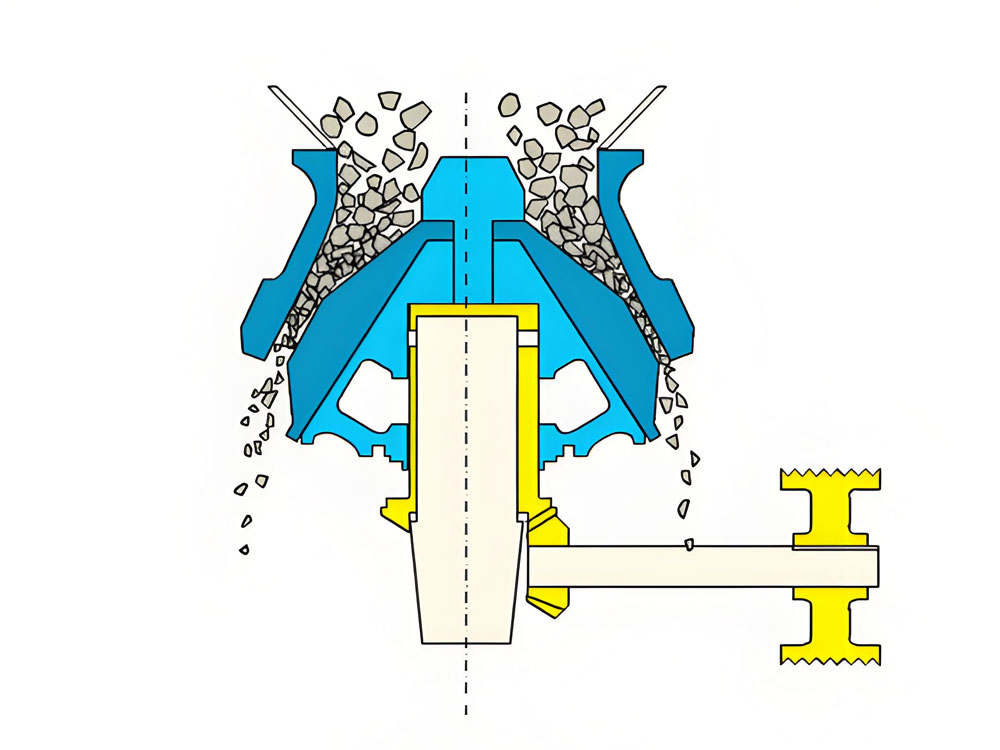

In modern mining and aggregate production lines, the crushing efficiency and processing capacity of the equipment are the key indicators of its performance. This equipment is designed based on the principle of gyratory continuous crushing, in which the crushing cone carries out a series of complex and orderly compound movements driven by the eccentric sleeve. This mode of movement creates a continuous extrusion, shearing and grinding effect on the material, thus realising a highly efficient crushing effect. Compared with the traditional jaw crusher, which operates in an intermittent mode, the processing efficiency of this equipment has been significantly improved by more than 30%.

Low energy consumption and operational stability

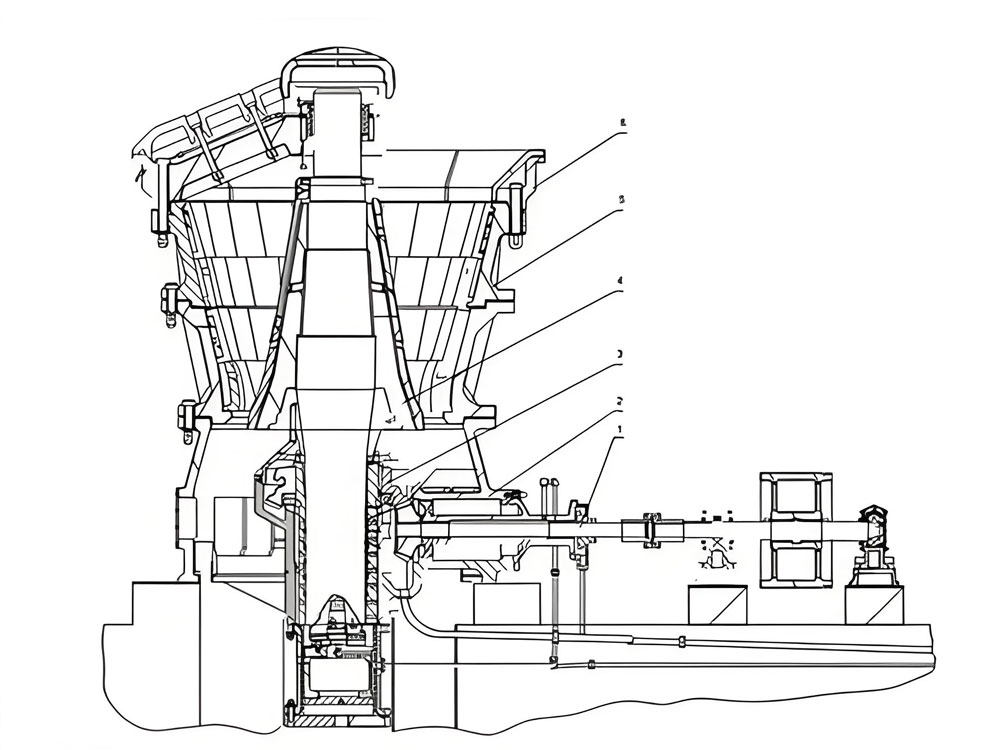

While pursuing high efficiency, we also pay great attention to the energy consumption and operational stability of the equipment. Through the synergistic design of the hydraulic system and the mechanical structure, the unit energy consumption of this equipment is significantly reduced compared with the traditional models, with a range of 15%-20%. The use of hydraulic drive technology not only realises the infinite adjustment of the discharge opening, which gives the equipment greater flexibility, but also has the overload protection function. When encountering the entry of non-crushed materials, the system will automatically adjust the position of the crushing cone and enlarge the discharge opening, thus effectively avoiding the damage of the equipment. The main shaft of the equipment is supported by heavy-duty bearings, combined with a precision gear transmission system, which significantly reduces the operating vibration of the equipment and effectively extends the life of key components. This not only improves the stability of the equipment, but also reduces the maintenance cost in the later stage.

Intelligent control and maintenance convenience

With the continuous development of science and technology, intelligence has become an indispensable part of modern equipment. CG850i is equipped with an integrated PLC control system, which can monitor the crushing force, bearing temperature, lubrication status and other key parameters in real time. Through the remote terminal, users can grasp the operating status of the equipment at any time, and carry out fault warning and optimisation of process parameters. This not only improves the operating efficiency of the equipment, but also greatly reduces the risk of failure caused by human factors. In terms of maintenance, this equipment also shows a high degree of convenience. The lubrication system with multi-point automatic oiling ensures that the bearings and gears operate with low wear, thus extending maintenance intervals to 1.5 times that of conventional equipment. At the same time, the modular design makes the replacement of liners easier and quicker, reducing the replacement time by 40% and keeping the maintenance window to less than 4 hours, which greatly improves the utilisation of the equipment.

Uniform product size and environmental compatibility

For crushing equipment, the uniformity of product size is one of the most important indicators of its performance. Through the optimised design of the crushing chamber curve, this equipment makes the material go through the process of graded crushing in multiple crushing zones. This not only improves the crushing efficiency, but also reduces the content of needles and flakes in the finished product to less than 10%, and the proportion of cubic aggregate reaches more than 85%, which fully meets the standard of high-end concrete aggregate. In terms of environmental protection, this equipment has also made positive contributions. Its closed structure with pulse dust removal interface reduces the dust emission concentration to below 20mg/m³, which fully meets the requirements of green mine construction. Users can directly connect the equipment to the plant's environmental protection system to achieve zero dust emission. This not only protects the environment, but also improves the social image of the enterprise.

Sell CG850i stationary gyratory crusher high efficiency coarse crushing Working Principle

It adopts high-precision conical crushing chamber, which forms a progressive crushing area between the moving cone and the fixed cone. The cone is driven by the eccentric bushing to rotate and oscillate, and the material is roughly crushed by squeezing, splitting and bending. The crushing chamber has built-in wear-resistant liners, the self-tightening rolling wall design prevents the liners from loosening and prolongs the service life, and the one-piece spherical upper arm bearing replaces the traditional liner, which improves the wear-resistance by 5 times and ensures the constant eccentricity. Driven by an electric motor, the power is transmitted to the eccentric sleeve through the reducer and transmission shaft, driving the dynamic cone to rotate with a specific trajectory. The rotating speed of the cone is matched with the eccentric distance to achieve continuous crushing action. The material enters into the crushing chamber from the top inlet, and when the moving cone is close to the fixed cone periodically, it generates high intensity extrusion and crushes the material; when the moving cone is far away from the fixed cone, the crushed material falls down and discharges from the bottom by gravity. Through the hydraulic system to adjust the height of the fixed cone or the position of the cone, to change the exit gap of the crushing chamber, to control the range of finished product size. Through the deep integration of mechanical design and intelligent control, this equipment solves the pain points of traditional gyratory crusher in terms of efficiency, stability and maintenance cost, and is suitable for large-scale ore coarse crushing scenarios.

Sell CG850i stationary gyratory crusher high efficiency coarse crushing Technical Parameters

| Feed opening | 1,549.0 mm | Power | 3000 tph |

| Weight | 500 tonne | Capacity | 1 150 mm |

| Horizontal Shaft | 500 rpm | Open side setting | 150.0 - 265.0 mm |