Uncover the technical innovation behind C130 jaw crusher

The C130 Jaw Crusher focuses on delivering outstanding crusher performance and meeting the diverse needs of our customers. The C130 Jaw Crusher consists of a fixed jaw and a movable jaw, which is connected to the drive through an eccentric shaft, allowing it to move up and down. A feed opening up to 1000mm (39 inches) deep handles larger feed materials and significantly reduces the need for blasting and crushing hammers. Non-welded frame construction ensures superior fatigue strength for extended crusher life. Lighter and more durable composite guards allow for quick and easy disassembly. The pin-and-bolt design facilitates down-hole installation and transportation, allowing for convenient installation in surface, underground and mobile applications. The C130 Jaw Crusher can also be customized according to different application requirements. Customers can choose different configurations and options to meet specific production requirements. This customization makes the C130 Jaw Crusher more flexible and versatile, and better able to adapt to a variety of complex working conditions and customer needs.

Uncover the technical innovation behind C130 jaw crusher Applications

In mining, C130 jaw crusher undoubtedly plays the important role of initial crushing of ores, providing just the right size of materials for subsequent processing. Its powerful crushing force and efficient operation efficiency undoubtedly make it occupy a pivotal position in the mining industry. Stepping into the construction industry, C130 jaw crusher also shines, whether it is crushing limestone, granite and other raw materials into basic materials for concrete and mortar, or converting construction waste into reusable recycled materials, all of which show its excellent crushing capacity and contribution to green development. In highways, railroads and other road projects, the stone materials crushed by C130 jaw crusher provide a solid guarantee for the laying of road base and pavement. Its efficient and reliable working performance is undoubtedly an important booster for the smooth progress of road projects. In addition, in chemical production, C130 jaw crusher also performs well in crushing coal, sulfur, phosphate and other raw materials, providing a stable and reliable guarantee for the supply of raw materials for chemical production. With the increasing awareness of environmental protection, C130 jaw crusher also plays an irreplaceable role in the field of environmental protection. It can crush municipal garbage, scrap iron and other wastes into smaller particles, which greatly facilitates the work of garbage disposal and resource reuse. It can be said that C130 Jaw Crusher is an excellent equipment that shows excellent performance and wide application value in many fields.

Uncover the technical innovation behind C130 jaw crusher Advantages

Intelligence and Automation

The C130 Jaw Crusher realizes real-time monitoring and intelligent adjustment of the crushing process by skillfully integrating sensors, controllers and other intelligent devices. This not only greatly improves the operating efficiency and stability of the equipment, but also allows the optional automation system to remotely monitor and adjust the crusher, feeder and conveyor, making the operation easier and more convenient than ever.

Safety and easy maintenance

The C130 Jaw Crusher also excels in safety. The flywheel and drive unit are equipped with safety guards to protect the operator from moving parts. At the same time, the equipment is also equipped with special lifting tools and reduced maintenance points, making maintenance work safer and more convenient. This design improves safety while significantly reducing maintenance costs.

Flexibility and Adaptability

The C130 Jaw Crusher can easily cope with various scenarios such as surface, underground and mobile applications with its flexible installation. The pin-and-bolt design of the C130 Jaw Crusher greatly facilitates underground installation and transportation, reducing installation costs. In addition, the equipment can be customized according to different processing materials and application scenarios, fully meeting the individual needs of different customers. This flexibility and adaptability makes the C130 jaw crusher widely used in mining, smelting, construction, highway, railroad and other fields.

Durability and Reliability

The C130 Jaw Crusher, with its pin-bolt connection and non-welded frame structure, exhibits excellent fatigue strength, thus extending the service life of the machine. The lighter and more durable composite guard makes disassembly and installation quick and easy, further enhancing the durability and reliability of the machine. At the same time, the key areas of the equipment are equipped with wear protection, and the design of vulnerable components and parts is easy to access and replace, effectively reducing maintenance costs.

High Crushing Efficiency and Productivity

The C130 Jaw Crusher ensures efficient crushing along the entire length of the crushing chamber, thanks to its small meshing angle and excellent kinematics. The large size of the crushing chamber, with a feed opening up to 1,000 mm (39 inches) deep, makes it easy to handle larger feed materials and significantly reduces reliance on blasting and crushing hammers. In addition, the larger stroke width at the bottom of the chamber helps to increase capacity and ratio, ensuring high throughput in a wide range of operations.

Uncover the technical innovation behind C130 jaw crusher Working Principle

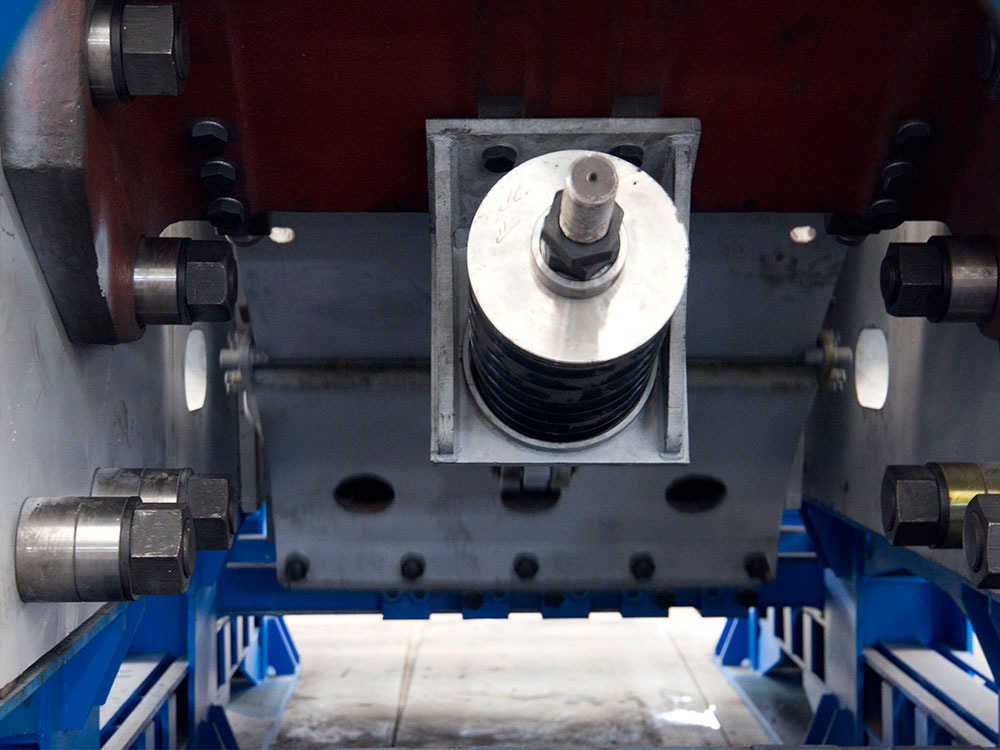

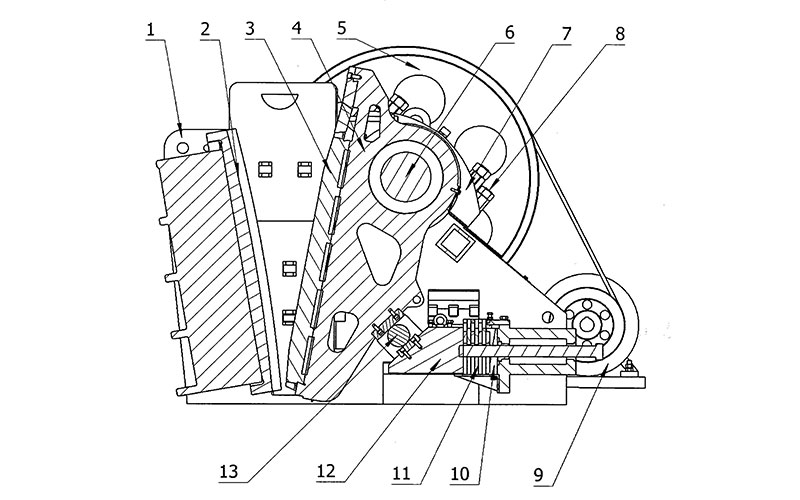

Jaw crusher mainly consists of frame, eccentric shaft, big pulley, flywheel, side guard plate, elbow plate, elbow plate back seat, clearance screw, reset spring, fixed jaw plate and movable jaw plate and other components. The crushing method belongs to the curved extrusion type. When working, the motor drives the belt and pulley to rotate and drive the movable jaw up and down through the eccentric shaft. When the movable jaw rises, the angle between the elbow plate and the movable jaw increases gradually, which pushes the movable jaw plate close to the fixed jaw plate, and the material is crushed by extrusion, rubbing and crushing between the two jaw plates. When the movable jaw moves downward, the angle becomes smaller, the movable jaw plate leaves the fixed jaw plate under the action of the tie rod and spring, and the crushed materials are discharged from the discharge opening at the lower part of the jaw cavity under the action of gravity. With the continuous rotation of the motor, the movable jaw periodically crushes and discharges the material, thus realizing mass production.

Uncover the technical innovation behind C130 jaw crusher Technical Parameters

| Weight | 40 150 kg | Power | 185 kW |

| Feed opening width | 1 200 mm | Operating speed | 220 rpm |

| Feed opening depth | 900 mm | Minimum Closed Edge Setting | 100 mm |