Hero Recycling Crusher Machine Sale

Customer: HerosSluiskil,Netherlands

Technical Data

Feed material: Slag from RIP‘s

Capacity: 40 t/h

Feed size: 0 – 150 mm

Product granulation: 0 – 40 with minimal oversize

Plant Description

At the „heart“ of the latest slag processing plant commissioned by Heros of Sluiskil in theNetherlandsis a new APPH 1010 Impact Crusher from . The slag from refuse incineration plants (RIP‘s) is selectively crushed by the impact crusher – in other words, the metal inclusions in the slag are freed from the non-metallic material for subsequent separation from the slag. This means that the metal can be recovered 100% for recycling, and the metal-free residue re-utilised, for example, in the building and construction industry.

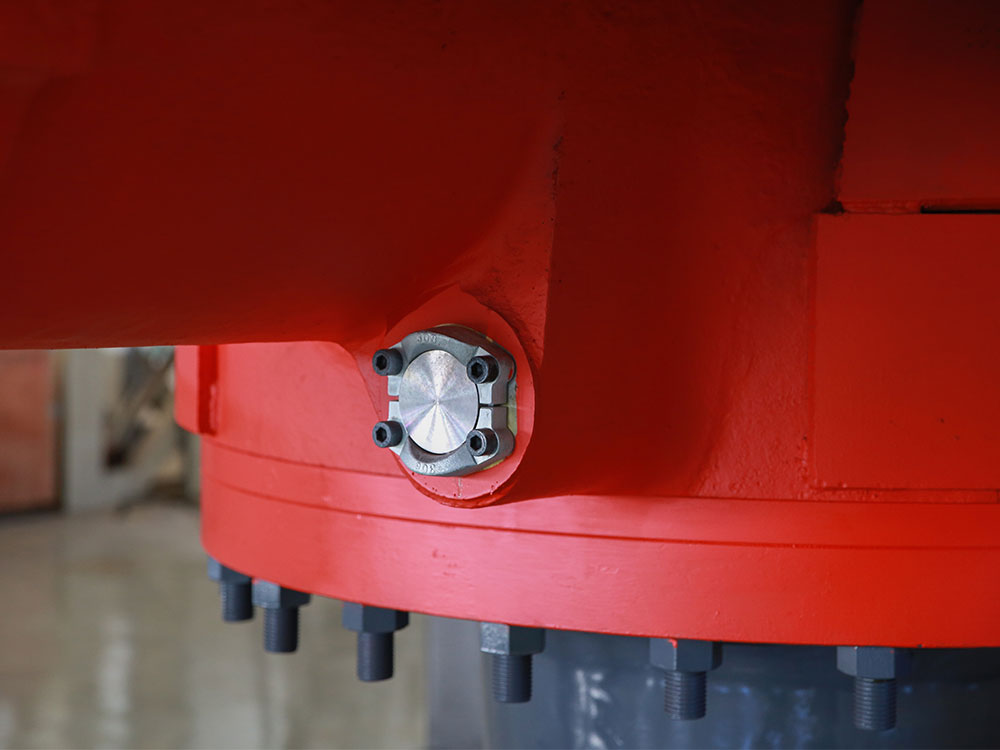

Initially, Heros used a second-hand crusher to collect information and gain experience with the project. The results with the crusher were excellent; however, the machine showed the signs of its age and wear, and so, following detailed discussions with specialists and a visit to a reference plant, Heros placed the order for the supply of a new crusher from the Dülmen works.The new machine is equipped with hydraulically-supported impact aprons, which can immediately retract on entry of non-crushables (i.e. tramp metal) into the crusher. The hydraulic control system offers a further big advantage in that the gap setting between the blow bars and impact aprons (which determines the overall product granulometry) can even be re-adjusted whilst the machine is in operation. In contrast to the previous models, the latest machine is equipped with a new labour-saving blow bar retention system, so that blow bar changing becomes even quicker and more simple.