Granite crushing Process in Russia

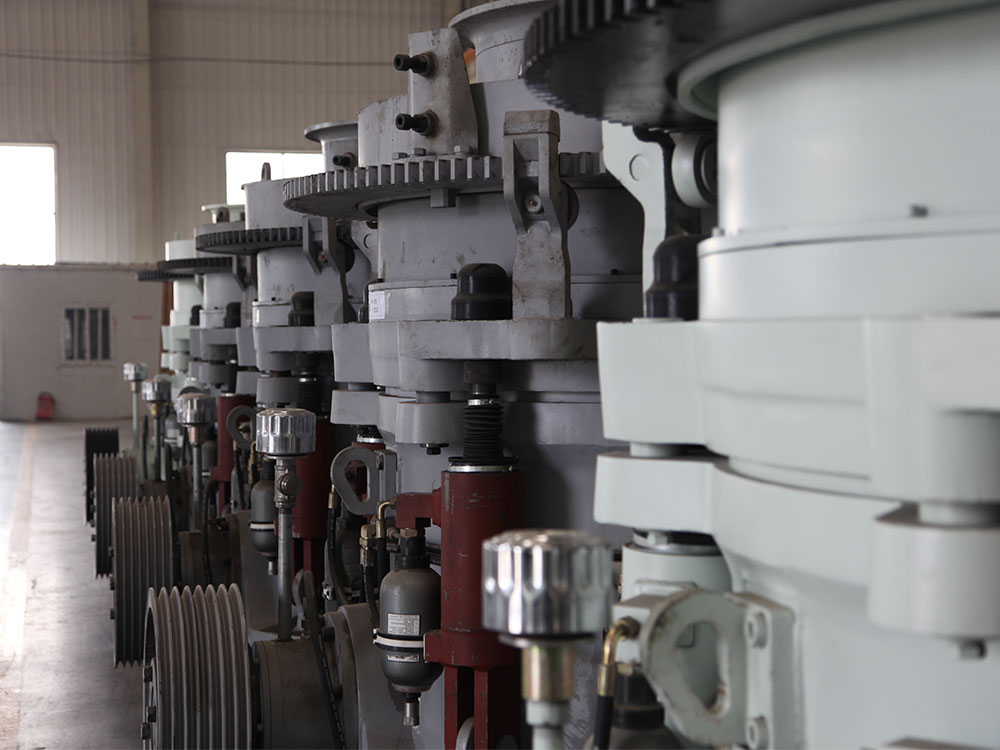

Procuction Process

The raw materials are unloaded by trucks into the primary hopper. By vibrating, the raw materials are regularly fed into Primary Jaw Crusher . The half-finished products from Jaw Crusher will be conveyed by Belt Conveyor. #1 and piled up into the storage hopper. Another Vibrating Feeder under the pile also feeds stones regularly into Belt Conveyor #2. By conveying, the stones are now fed into Cone Crusher. After crushing by Cone Crusher”, through Belt Conveyor #3 & #5, the materials are conveyed into Vibrating Screens to be separated as 0-5mm, 5-20mm, 20-40mm and +40mm.

The substandard Stones which are bigger than 40mm return into Cone Crusher by Belt Conveyor #4 for further crushing, and the rests are piled by Belt Conveyor #6. Scraps from grate of the primary vibrating feeder are conveyed by Belt Conveyor #7 as another pile.

Case Study

A Crushing Plant invested by Russia Government intends to crush Granite Stones for road construction. The detailed requirements are as following:

Raw material: Granite

Feeding Size: 800mm Output size: 0-5mm, 5-20mm, 20-40mm

Feedback From The User:

Lower energy consumption, Longer service life, Lower cost of spare parts, Higher performance cost ratio, Perfect products.