What is a desulfurization pulverizing equipment?

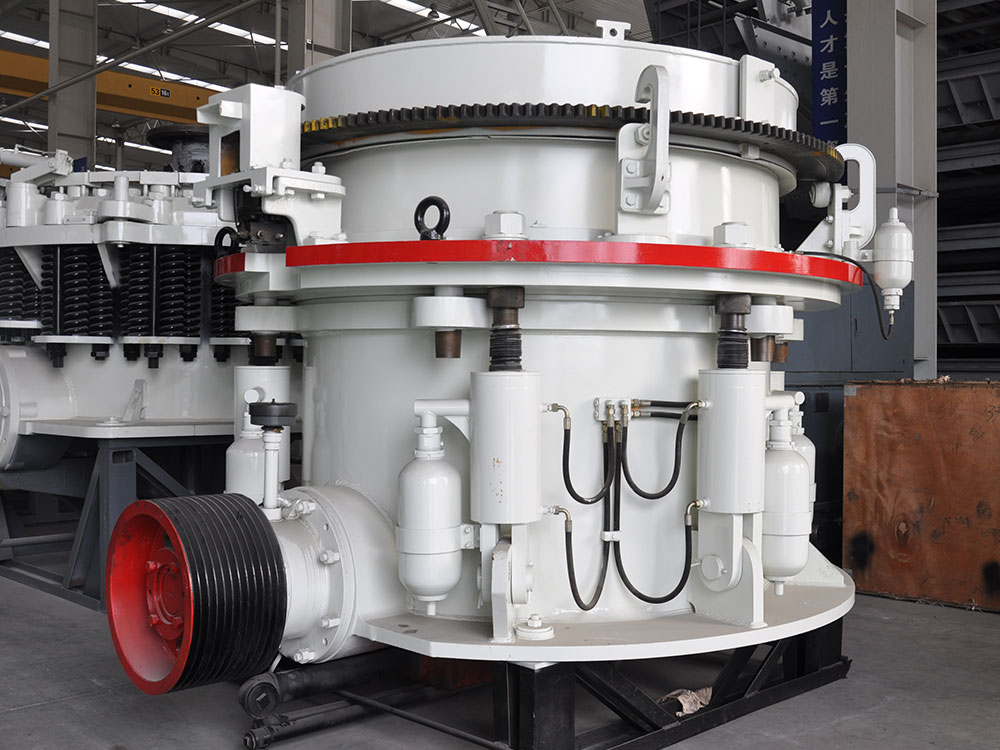

General, desulfurization of coal pulverizing equipment is medium high voltage and the principle of continuous rolled pieces repeatedly, after the widely absorbed better technology combined with your manufacturers and market experience, research and development to produce a set of grinding, drying and sizing equipment. Rollers and its main components for general mill, raw materials by stress and shear stress were shattered. Henan Liming heavy industry science and technology co., LTD., is producing many types of desulfurization of coal pulverizing equipment.

Our company's mill equipment for desulfurization and milling has European mills, trapezoidal mills, vertical roller mills and intelligent mills, etc., all of which have their own advantages and areas of expertise. In recent years, the desulfurization and milling of power plants has been favored and praised by customers. It is the MTW European version of the grinding machine. This type of grinding machine is a national patent product developed by our company on the basis of absorbing European grinding technology and concept. A number of independent patent technology property rights. This model adopts a series of new patented technologies such as bevel gear integral transmission, internal thin oil lubrication system and curved air duct. The grinding efficiency is high and the output is increased by more than 20%. It is a replacement for traditional Raymond mill and pendulum mill. Products are widely used in power plant desulfurization, large non-metallic mineral milling and building materials and chemicals.

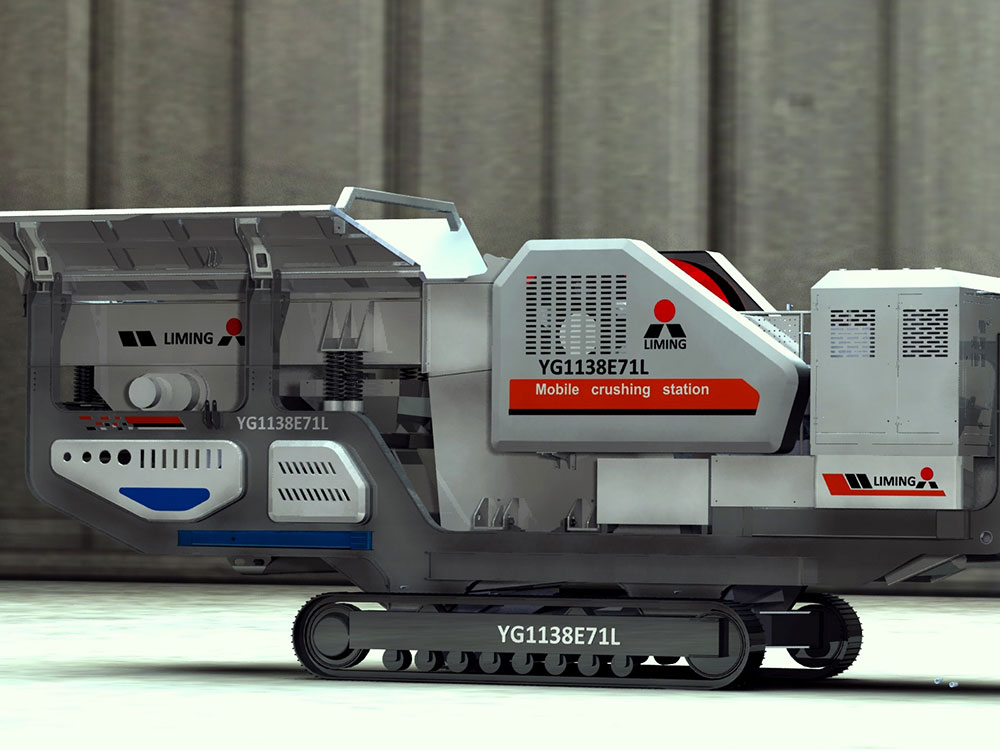

In addition, our company has introduced a 5X series fifth-generation European version of the intelligent mill, which can be applied to environmentally-friendly limestone desulfurization and milling, heavy calcium carbonate grinding, large non-metallic mineral milling, building materials, Chemical, solid fuel grinding, etc. It has a new type of intelligent grinding equipment with unique structural design, full thin oil lubrication system, low-resistance curved air duct and many other proprietary technology. The high-capacity, low-energy, safe and advanced intelligent mill is also the preferred equipment for large-scale mineral processing scale construction and environmental protection and intelligent production.