Jaw crusher high maintenance costs

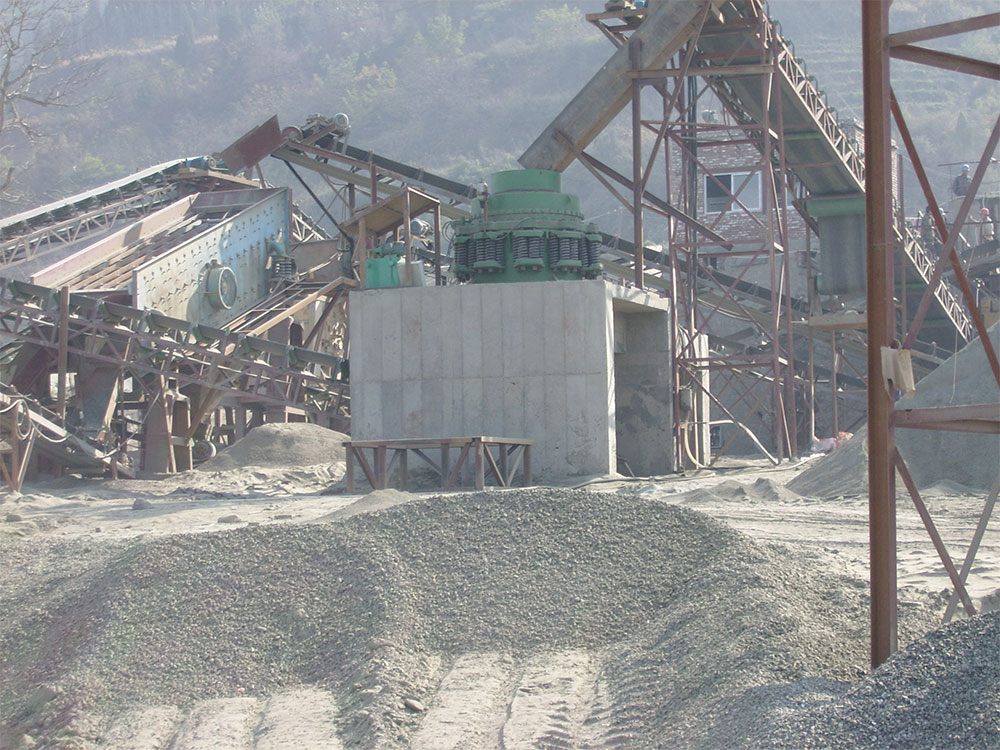

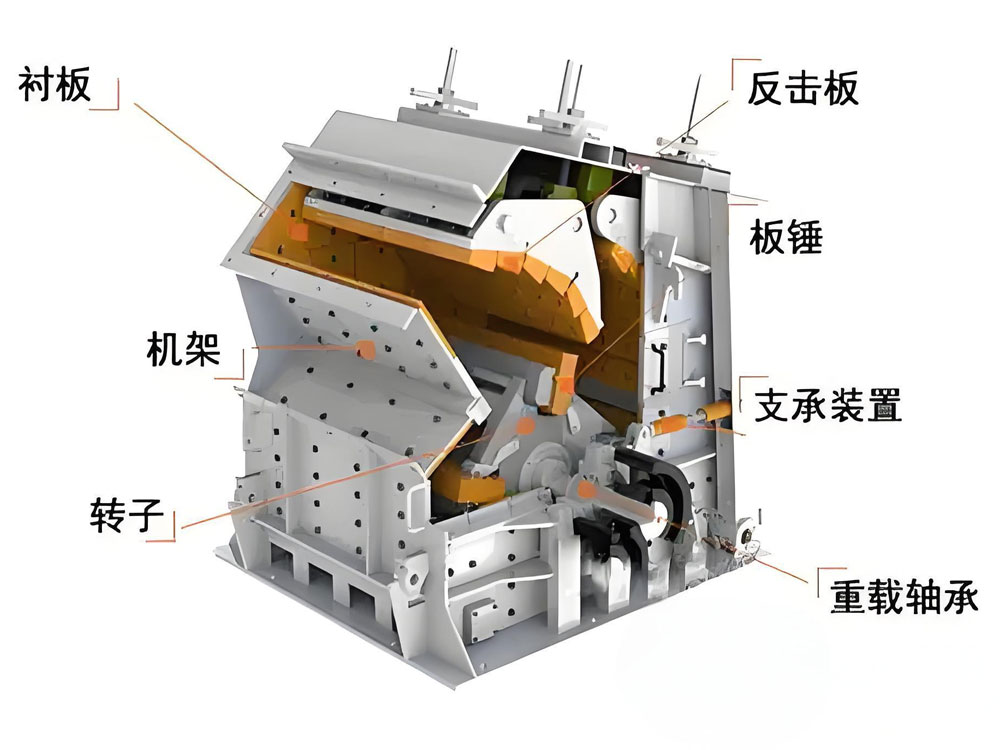

Jaw crusher is one of my company produces a new type of crusher machine, this machine is my company combines old-fashioned crusher before improved and designed on the basis of a new kind of crushing machine. The machine is to replace the old-fashioned crusher is a new generation of products, the most suitable for use in the new stone or sand production in the production of the old equipment renovation of the old production line. Abandoned the previous old design characteristics of the crusher, the use of new type hydraulic broken way, the size and the shape of the stone from the well, granularity, and large capacity, high production efficiency, broken than large, low energy consumption advantages, has been widely used.

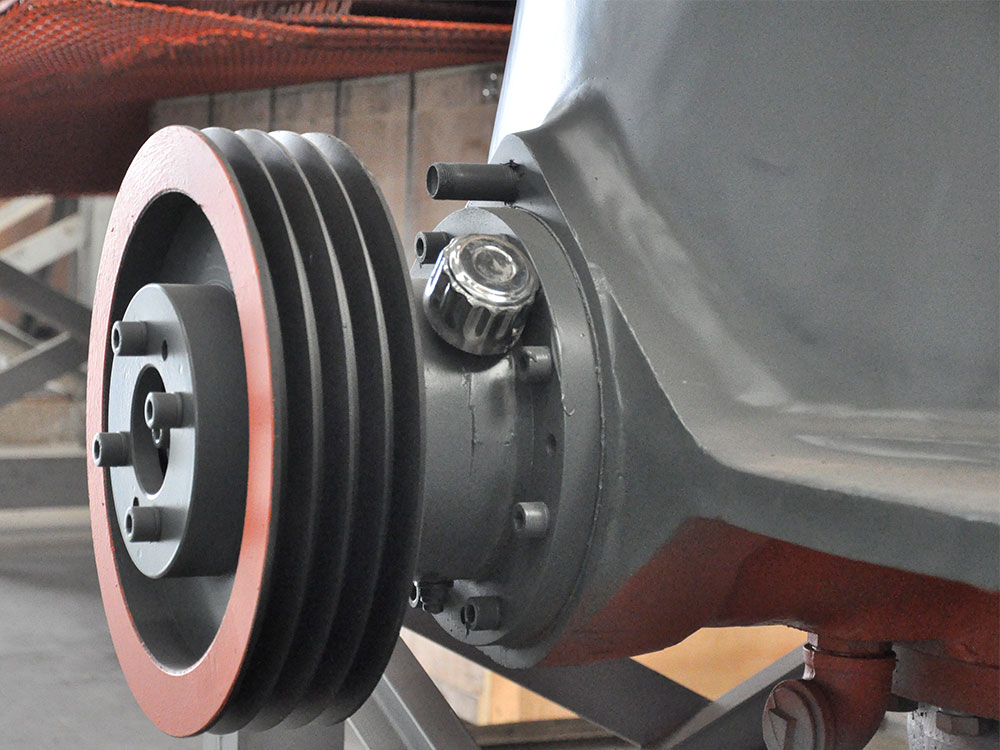

Jaw crusher work mainly has two pieces of jaw, namely fixed jaw and moving jaw moves up and down for broken, so are the most common components in the jaw crusher wear, need to use when designing and manufacturing high strength and high wear resistance of the material to produce. The strength of the jaw crusher jaw in the standard structure, are using it as a general insurance parts, so to reduce the safety coefficient calculation. Design Suggestions to its allowable stress by 25 ~ 30%. In order to weaken the cross section of the thrust plate, sometimes along its width direction cloth has a hole.

When calculating the strength of jaw crusher thrust plate, are generally according to the broken motor to determine the width of jaw thrust plate width, again by the width to the thickness of the thrust plate. According to the requirements of the jaw strength of the material we use is manganese steel, manganese steel has the following high strength and abrasion resistance. Manganese steel is a kind of high strength wear-resistant steel, mainly used in the need to withstand shocks, extrusion, material wear bad working conditions, such as damage form is given priority to with wear consumption, part of the rupture, deformation. Wear can be divided into three types: metal component surface interaction and movement between the friction and wear; Other metal or nonmetal materials against metal flowing gas or liquid on the surface of the abrasive wear and contact with the metal lead to erosion abrasion. Wear resistant steel wear-resisting performance depends on the material itself, and the anti-wear steel are different under different working condition of wear resistance, working conditions of material itself and both can decide its wear resistance.

Jaw crusher teeth plate adopt high strength manganese steel production, greatly reduced the change frequency, easy loss components directly reflected in the equipment maintenance cost and equipment of continuous reliability. Later with the development of material science, we may have better strength and abrasion resistance material better, to make life more long jaw crusher.