In order to meet the demand for high-quality sand and gravel aggregates in the infrastructure field, we need to finely process raw materials such as granite, pebbles, quartz and basalt. So, what key equipment do we need in the processing process? What is the process flow of these equipment? How to configure them efficiently? Next, let us enter the world of the 10 million tons per year sand and gravel aggregate production line.

This production line consists of five core systems: crushing, screening, sand making, sand washing and dust removal. The configuration of equipment needs to be closely combined with material characteristics, site conditions and finished product requirements to achieve the best production effect.

When configuring a 10 million tons per year sand and gravel aggregate production line, we need to pay attention to the following points:

1. Raw material hardness and equipment selection: For stones with higher hardness, such as granite and river pebbles, we recommend using a jaw crusher for coarse crushing, a cone crusher for medium and fine crushing, and a sand making machine to complete the final sand making. For medium and soft materials, a combination of jaw crusher + impact crusher + sand making machine can be selected.

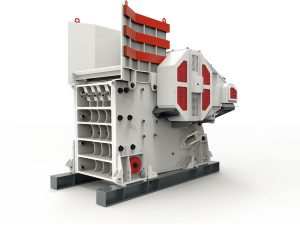

2. Crusher performance and crushing ratio: Jaw crusher is the first choice for coarse crushing due to its powerful crushing capacity and efficient discharging performance. Cone crusher, impact crusher and hammer crusher are more suitable for medium and fine crushing due to their good particle shape control ability. When choosing, the hardness of the material and the required crushing ratio should also be fully considered.

3. Production line output and equipment matching: The equipment type and model of the gravel production line need to be accurately matched according to the expected output, raw material characteristics and processing capacity. Through reasonable equipment configuration and process design, the stable operation and high production and efficiency of the production line can be ensured.

In terms of process design, we also pay attention to details and innovation:

Crushing system: The first stage crushing adopts a single-stage hammer crusher to ensure the rapid crushing of large pieces of material; the second stage crushing uses an impact crusher to further refine the material particle size.

Screening and conveying: Through efficient screening systems and flexible conveying equipment, accurate grading and rapid transportation of materials can be achieved.

Environmental protection and energy saving: Throughout the production process, we always pay attention to environmental protection and energy saving. By adopting advanced dust removal equipment and energy-saving technology, dust emission and energy consumption levels can be effectively reduced.

At the same time, we also provide a full range of service support, from equipment selection to installation and commissioning to after-sales service, to ensure that customers can enjoy a worry-free experience. If you have any questions or needs, please feel free to contact us.