The CS840i stationary cone crusher represents a revolutionary advancement in crushing technology, combining a double-chamber design with robust engineering to deliver unmatched efficiency and versatility. Designed for heavy-duty applications, this crusher is ideal for mining, quarrying, and aggregate production. Its innovative architecture ensures high productivity, reduced downtime, and adaptability to diverse material types.

Working Principle of the CS840i Double-Chamber Cone Crusher

Dual Crushing Zones for Enhanced Efficiency

The CS840i stationary cone crusher employs a unique double-chamber design that divides the crushing process into two distinct stages: primary and secondary. The upper chamber handles coarse crushing, breaking large feed materials into manageable sizes. The lower chamber then refines these particles to the desired final product specifications.

This dual-zone approach minimizes recirculation loads and reduces energy consumption by 15–20% compared to traditional single-chamber crushers. The hydraulic adjustment system allows operators to fine-tune the discharge setting dynamically, ensuring consistent output quality even with fluctuating feed conditions.

Key Technical Parameters of the CS840i Cone Crusher

Engineered for Performance

The CS840i stationary cone crusher is built to handle demanding workloads. Below are its core technical specifications:

Max Feed Size 450 mm (17.7 in)

Capacity 500–1,200 t/h

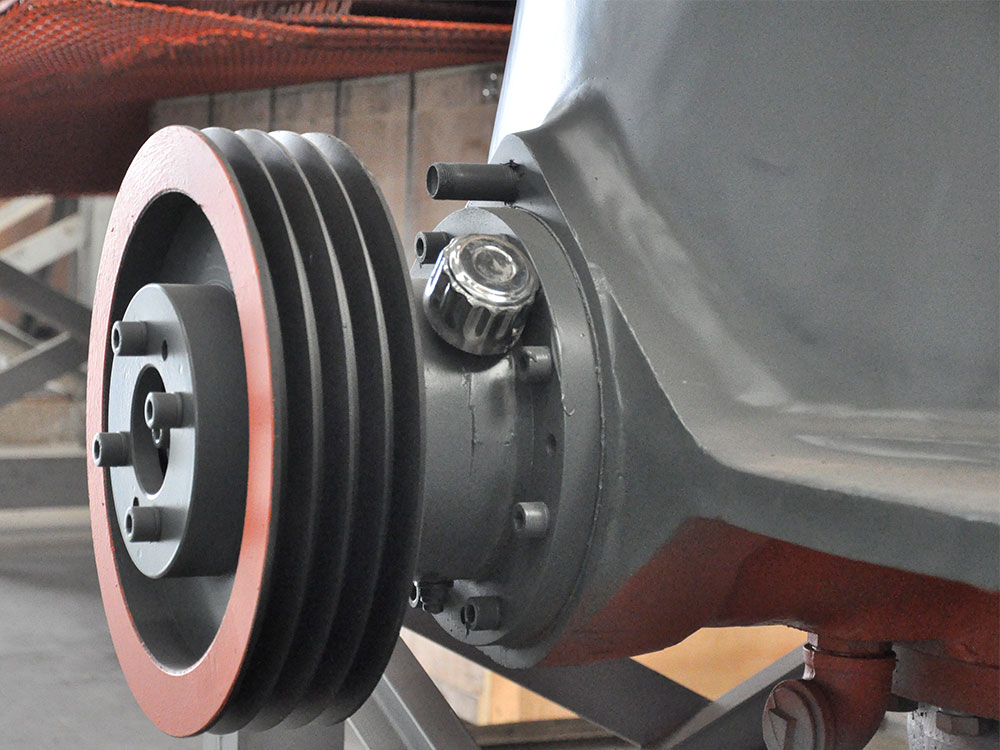

Motor Power 315 kW (422 hp)

Crusher Weight 24,200 kg (53,350 lbs)

Discharge Range 19–51 mm (0.75–2.0 in)

Chamber Options Coarse, Medium, Fine, Extra-Fine

These parameters make the CS840i double-chamber crusher suitable for processing hard and abrasive materials like granite, basalt, and iron ore, while maintaining high throughput and low operational costs.

Application Scenarios for the CS840i Double-Chamber Crusher

Mining and Quarrying Operations

The CS840i stationary cone crusher excels in large-scale mining and quarrying environments. Its double-chamber design allows for continuous processing of oversized rocks, reducing the need for primary jaw crushers in certain configurations. For example, in copper mines, the crusher’s ability to handle high-pressure crushing ensures efficient liberation of valuable minerals.

Aggregate Production for Construction

In aggregate plants, the CS840i cone crusher delivers uniformly shaped end products critical for road construction and concrete manufacturing. The dual chambers enable precise control over particle size distribution, meeting strict industry standards such as ASTM and EN.

Recycling and Secondary Crushing

The crusher’s adaptability extends to recycling applications, where it processes demolition waste, concrete, and asphalt. The hydraulic tramp release system protects the machine from uncrushable materials, making it ideal for urban recycling facilities with variable feed composition.

Advantages of the Double-Chamber Design in the CS840i

Operational Efficiency and Cost Savings

The CS840i’s double-chamber configuration optimizes energy use by distributing wear evenly across both crushing zones. This extends component lifespan and reduces maintenance frequency. Additionally, the crusher’s automated control system monitors performance in real time, adjusting settings to maximize output while minimizing downtime.

Flexibility Across Material Types

Whether processing soft limestone or hard quartzite, the CS840i stationary cone crusher adapts seamlessly. Operators can switch between chamber profiles (coarse to extra-fine) within minutes, making it a versatile solution for multi-product operations.

Case Study: CS840i Crusher in a Granite Quarry

Problem Statement

A granite quarry in Scandinavia faced challenges with inconsistent product gradation and excessive wear on their existing single-chamber crusher.

Solution with the CS840i Double-Chamber Crusher

After installing the CS840i stationary cone crusher, the quarry achieved:

- 22% increase in throughput.

- 30% reduction in energy costs.

- Extended liner lifespan due to balanced wear distribution.

The dual-chamber system allowed simultaneous production of two aggregate grades, eliminating the need for a secondary crushing unit.

Maintenance and Longevity of the CS840i Cone Crusher

Simplified Service Procedures

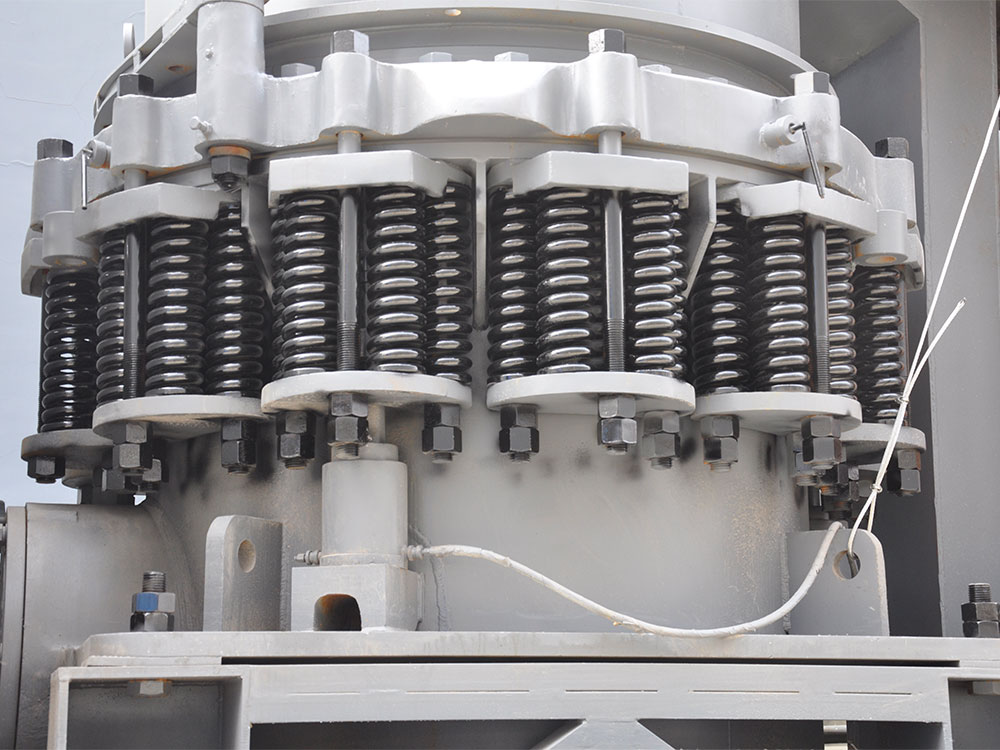

The CS840i cone crusher features a modular design for easy access to critical components. Key maintenance highlights include:

- Tool-free adjustment of the crushing chamber.

- Replaceable wear plates to protect the main frame.

- Centralized lubrication system for hassle-free upkeep.

These features ensure the CS840i double-chamber crusher operates at peak performance for over 10,000 hours between major overhauls.

Future Trends: Integration with Smart Technologies

The CS840i stationary cone crusher is poised to integrate with Industry 4.0 frameworks. Upcoming upgrades include IoT-enabled sensors for predictive maintenance and AI-driven optimization algorithms. These innovations will further cement the CS840i’s double-chamber design as a benchmark in crushing technology.

The CS840i stationary cone crusher redefines efficiency through its double-chamber design, offering unparalleled adaptability across mining, recycling, and aggregate sectors. With robust technical parameters, reduced operational costs, and future-ready engineering, it stands as a superior investment for businesses prioritizing productivity and sustainability.

By leveraging its dual crushing zones and intelligent automation, the CS840i cone crusher not only meets but exceeds the demands of modern material processing. Explore how this innovative machine can transform your operations today.